A group project by Ollie, Kiefer, Ian and Asa

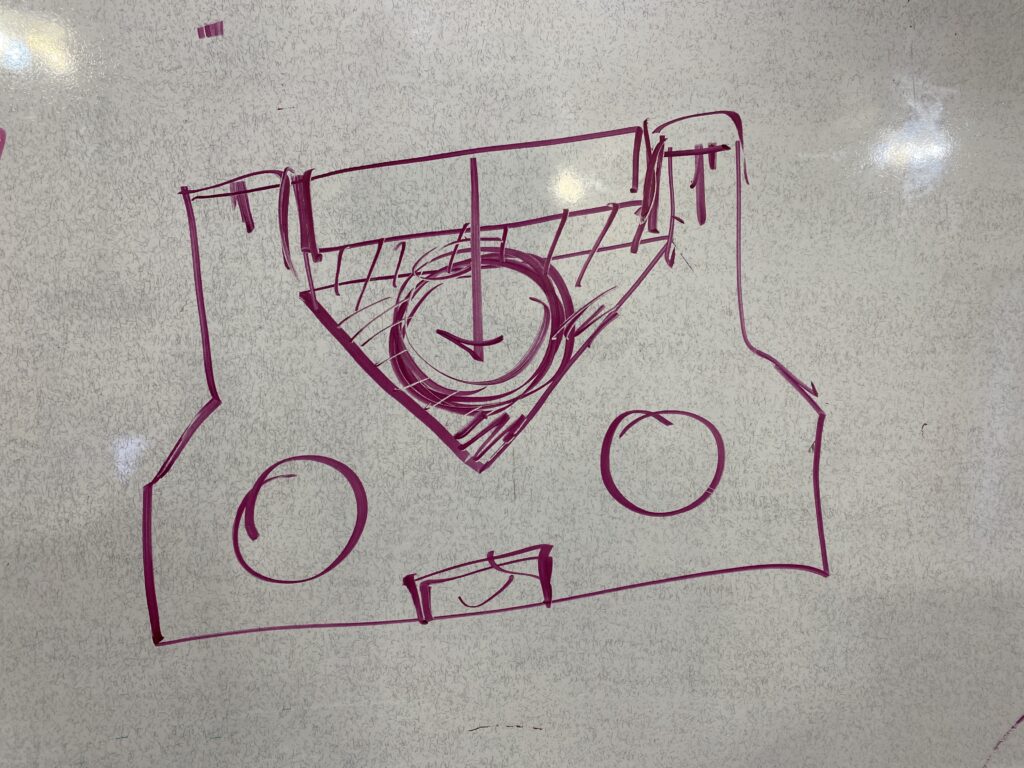

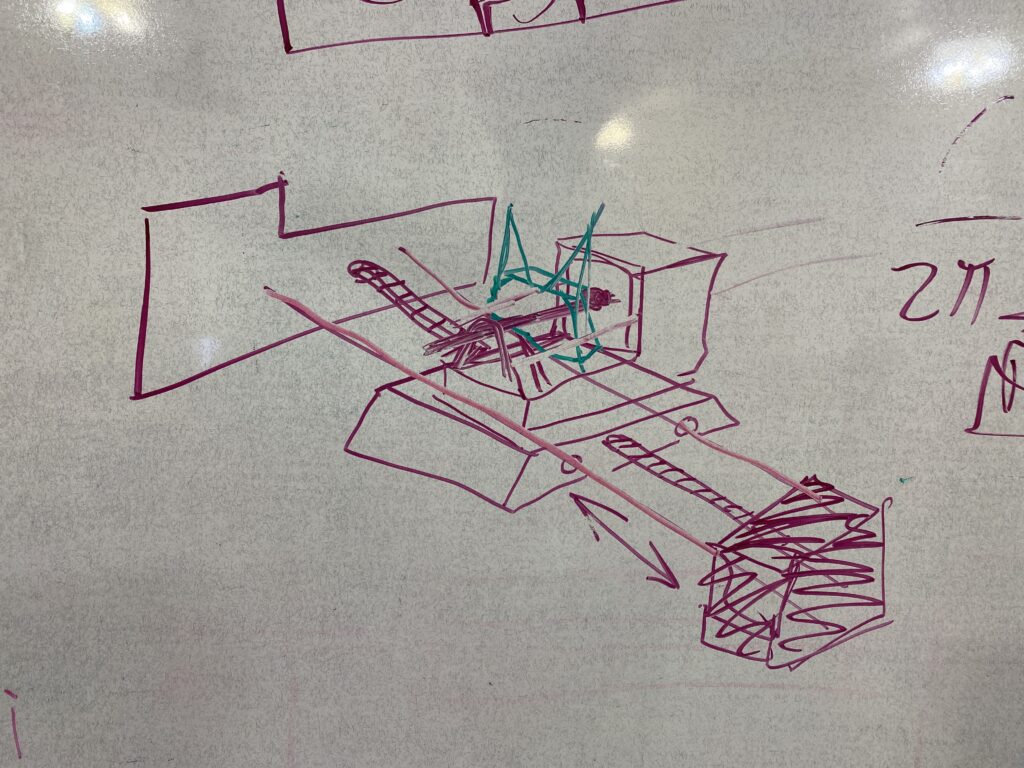

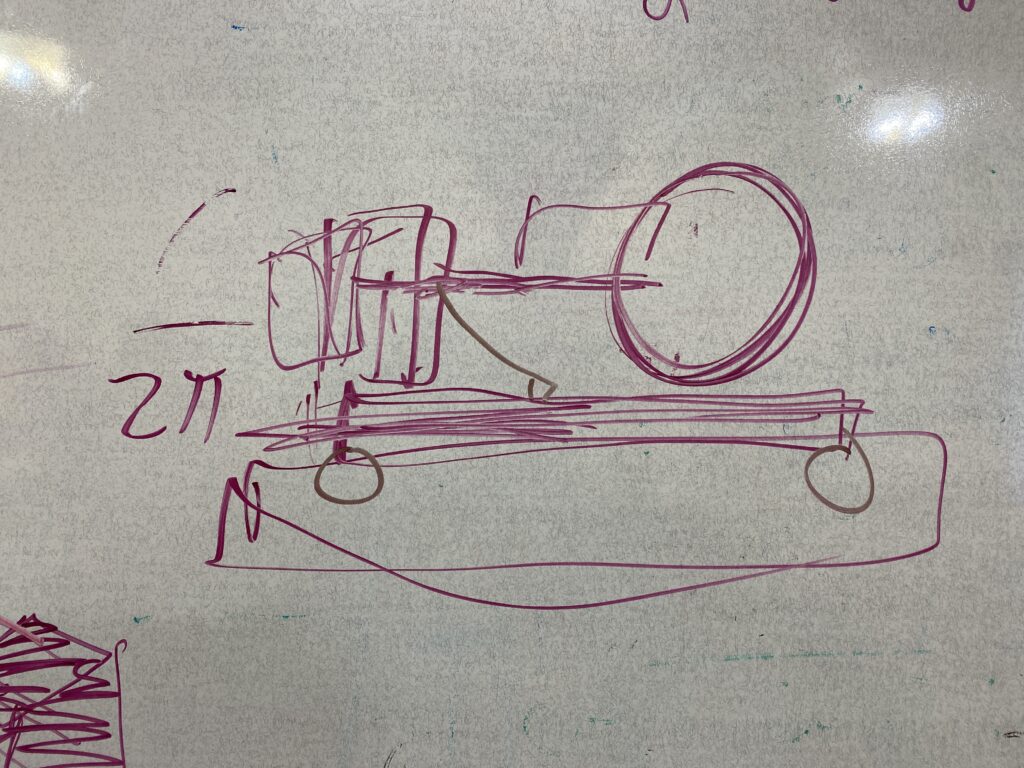

Ideation

Our project’s goal was to create a machine that would be able to convert sounds into a three dimensional object. We were also really interested in creating a machine that could be a tool that creates, and wanted to make the process somewhat adaptable so that other tools and materials could be swapped in.

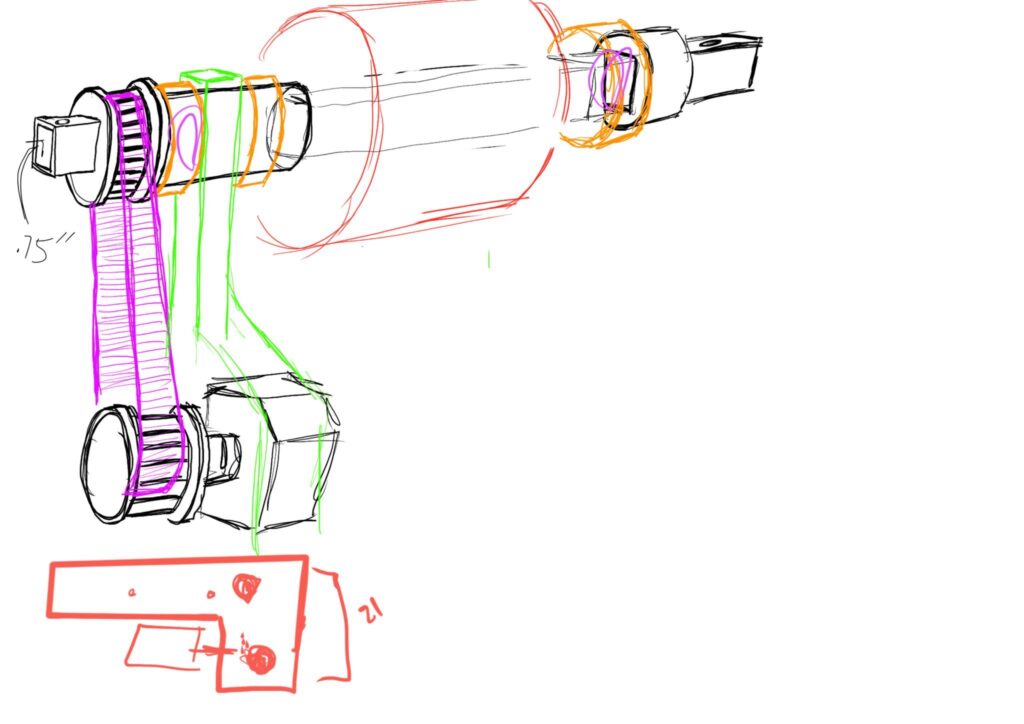

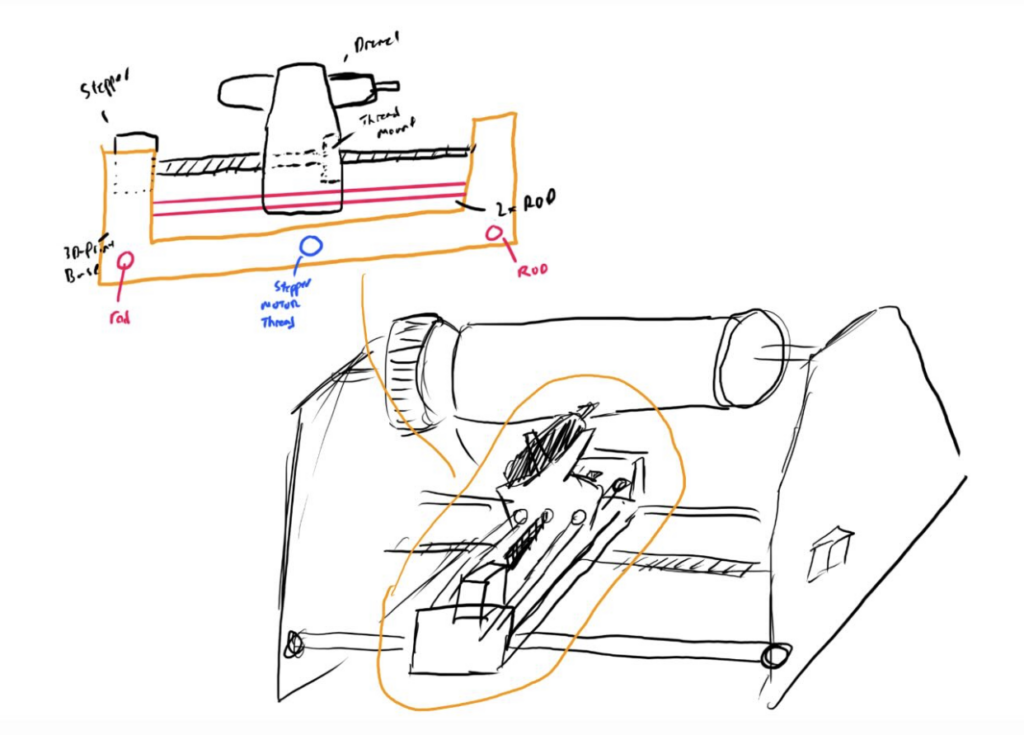

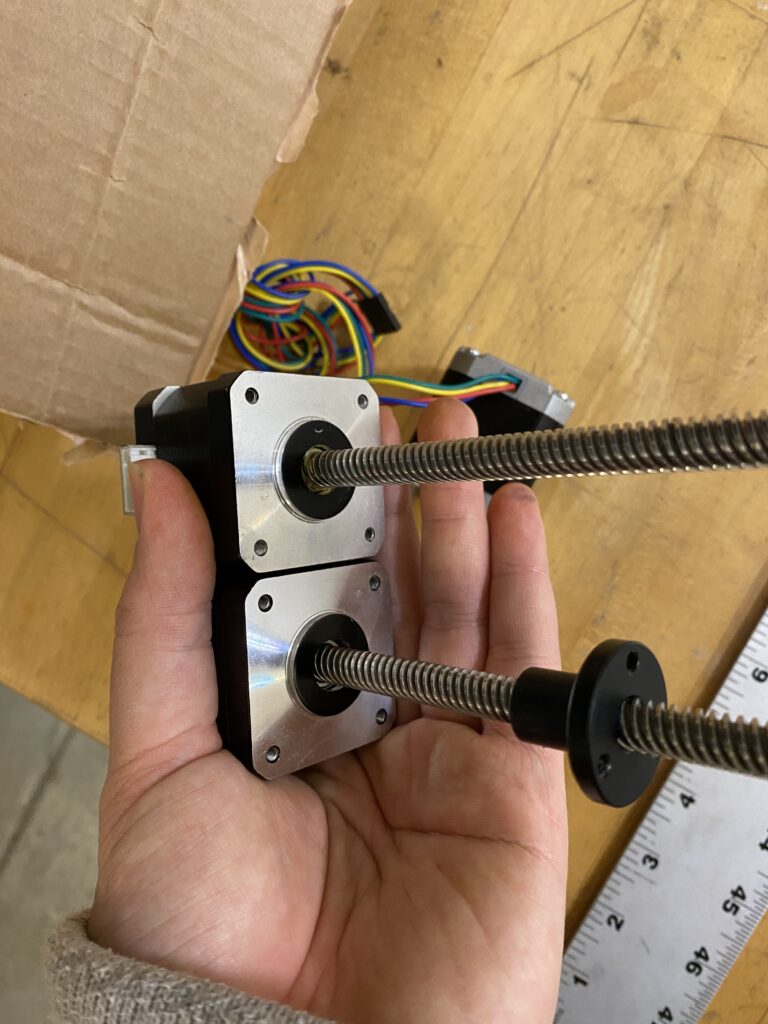

Our initial ideas took us on several different routes and we settled on creating a laithe that would be able to carve into a cylinder of clay. It took a while to figure out the forms in which each part of our machine would take, as we were starting from scretch with the only pre made parts being the motors, belt gears, and metal bars.

You can view our Ideation and Planning in our Google Doc here!

Process

The creation of the machine had many hiccups, and each part took several iterations to work, and some several more to work with other parts. Working out the GH file and firefly took a while too, as did calibrating the firmware.

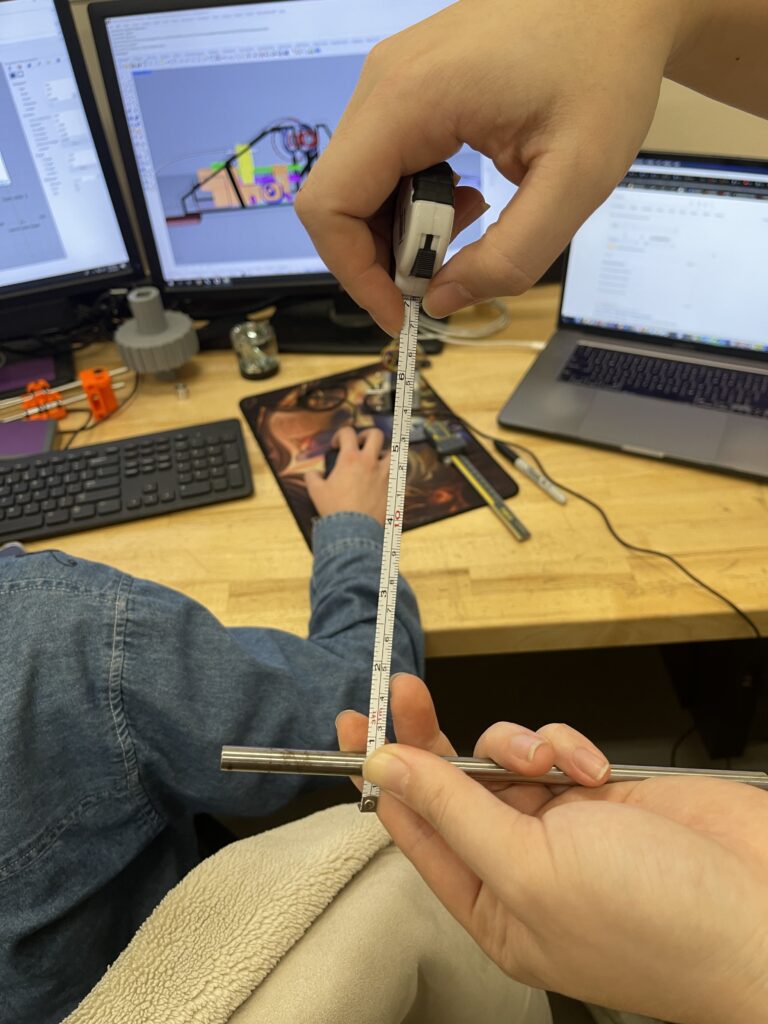

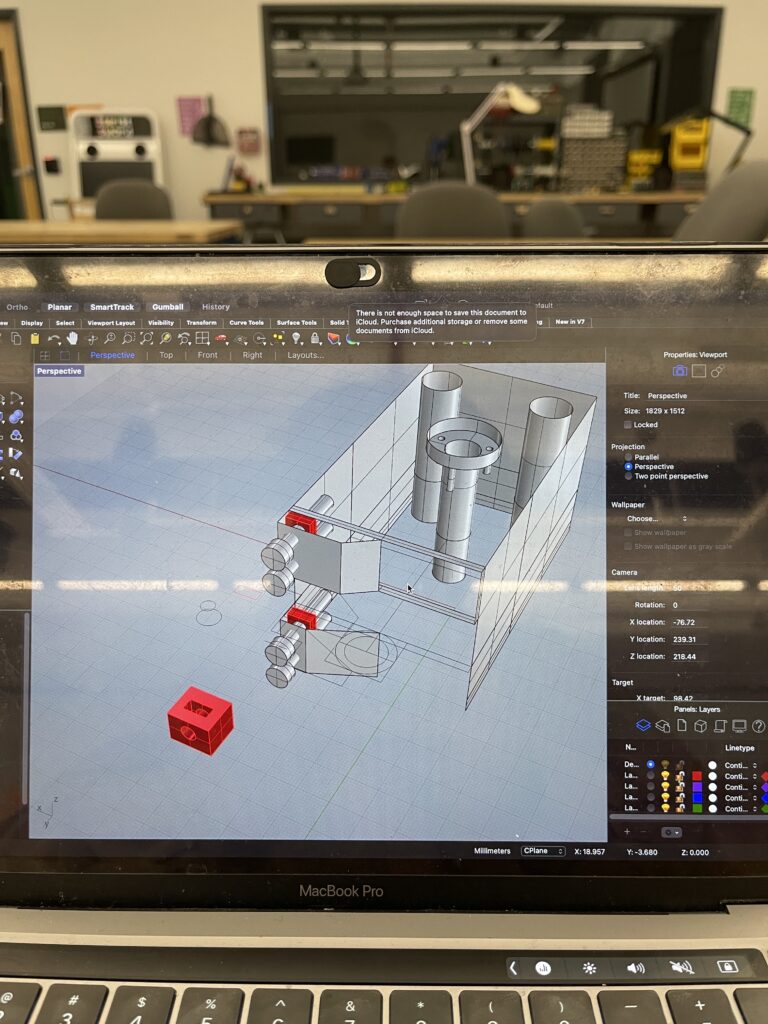

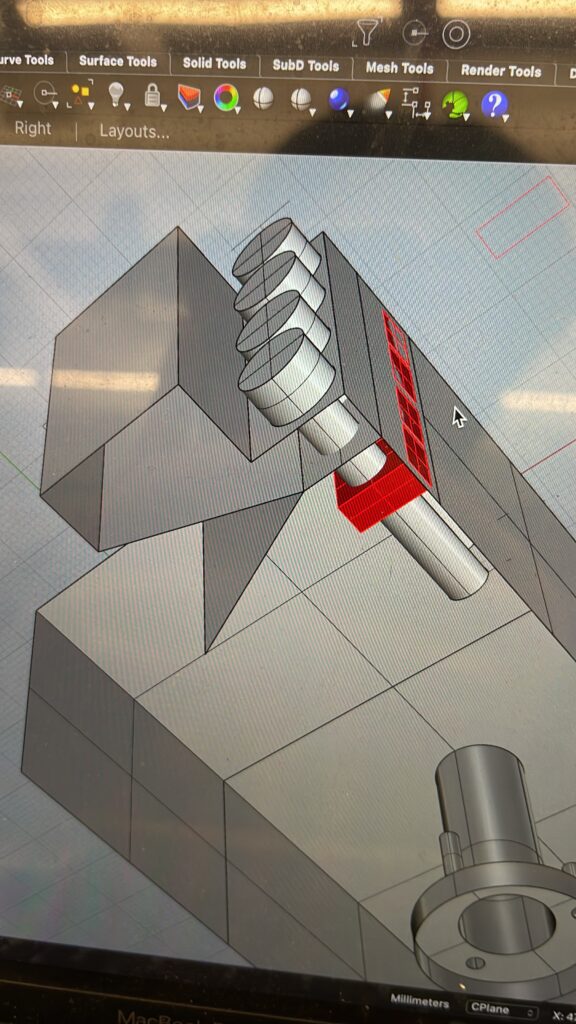

Measuring dimensions and figuring out how to build in 3D parts in Rhino

Working in Rhino to prepare 3D files for printing

3D Printing in progress: Our 3D models are rather big so it usually takes around half a day to completion :'(

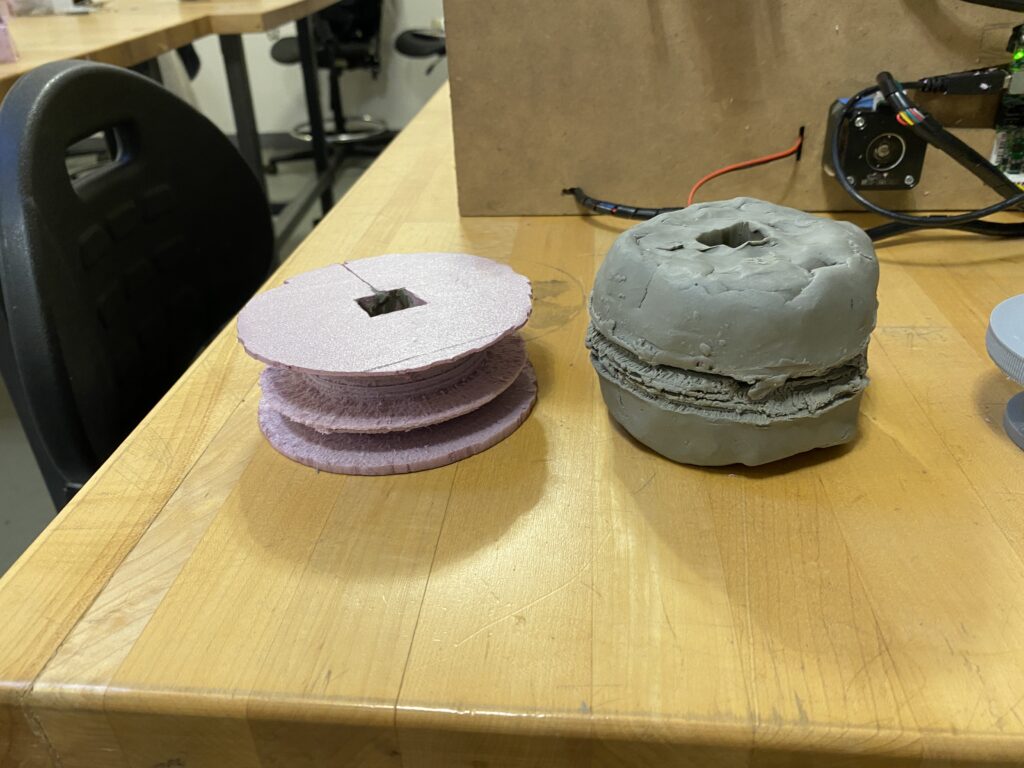

Having to reprint several times due to printing errors or miscalculations to get the perfect model part that fits into the machine.

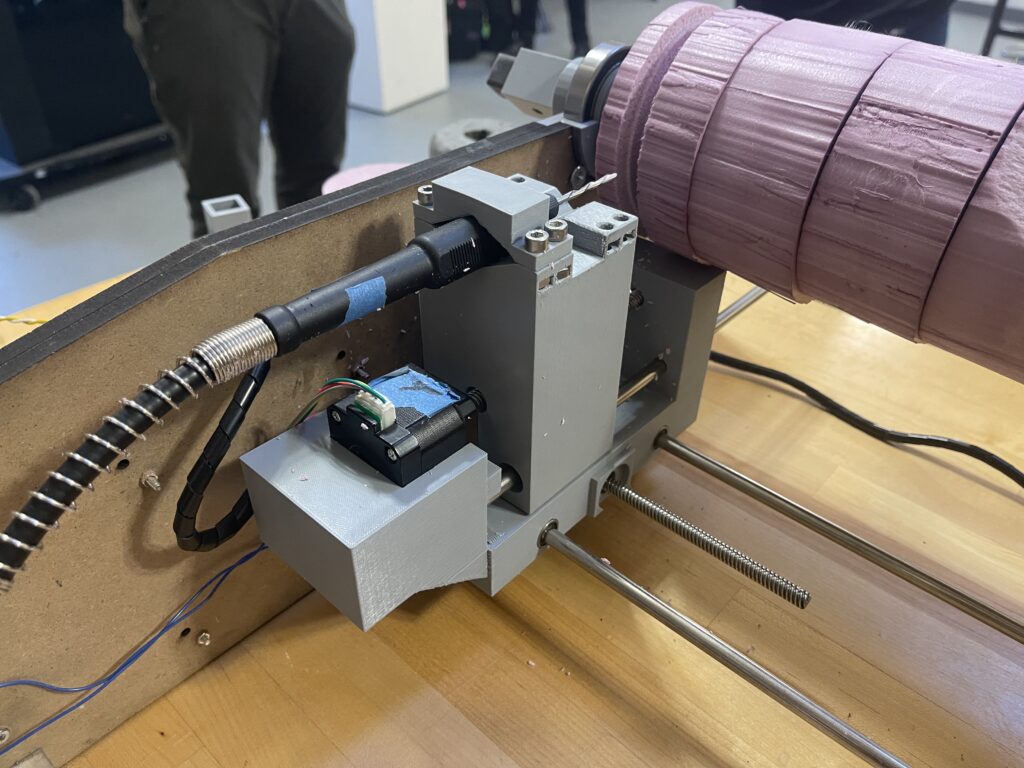

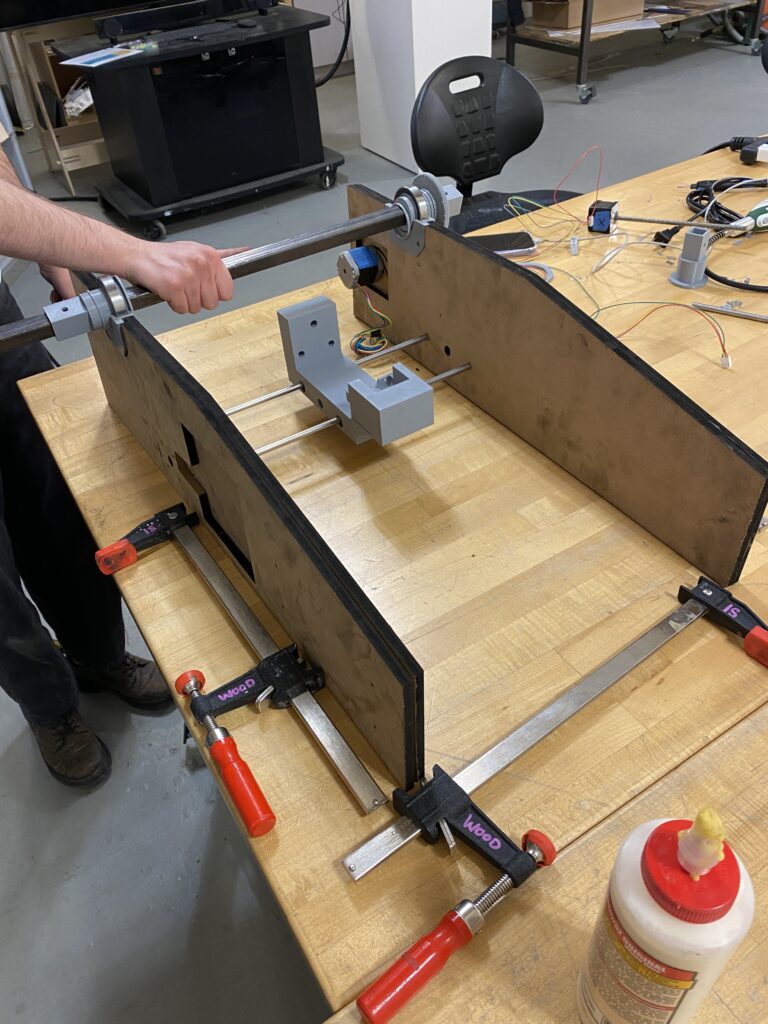

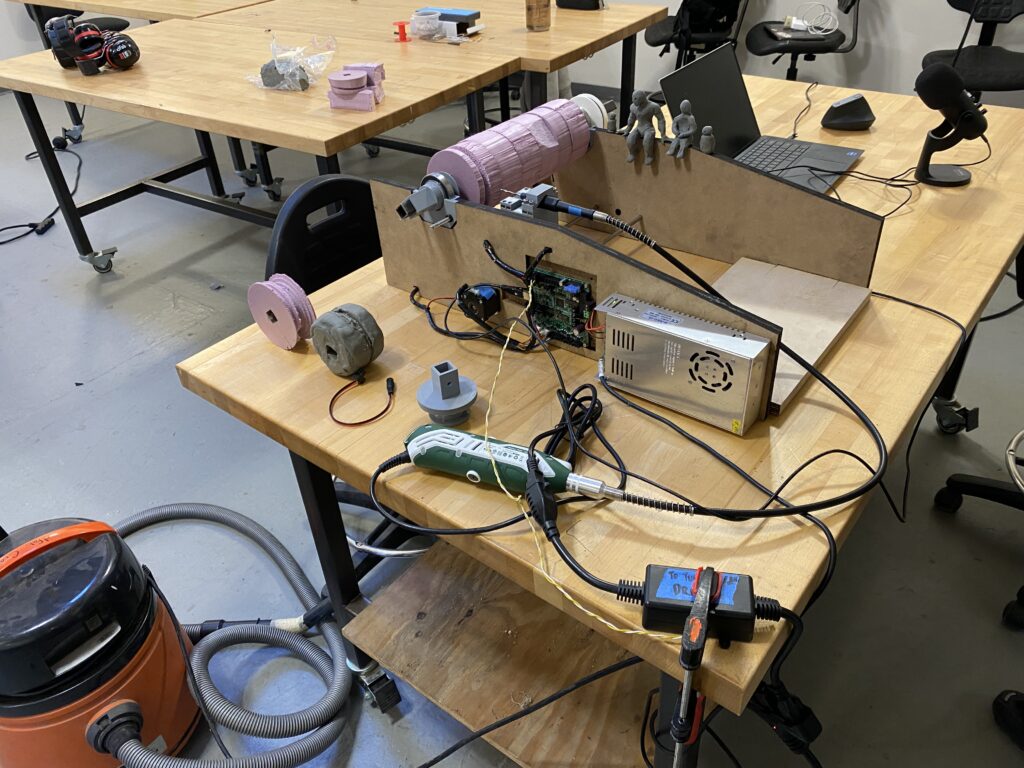

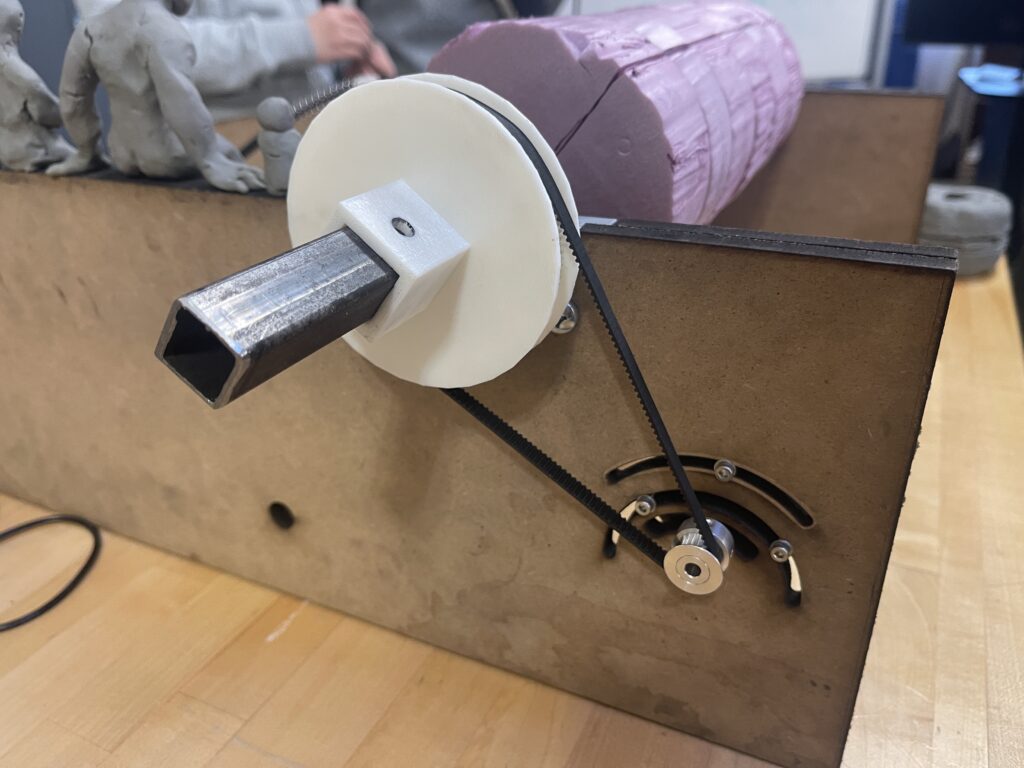

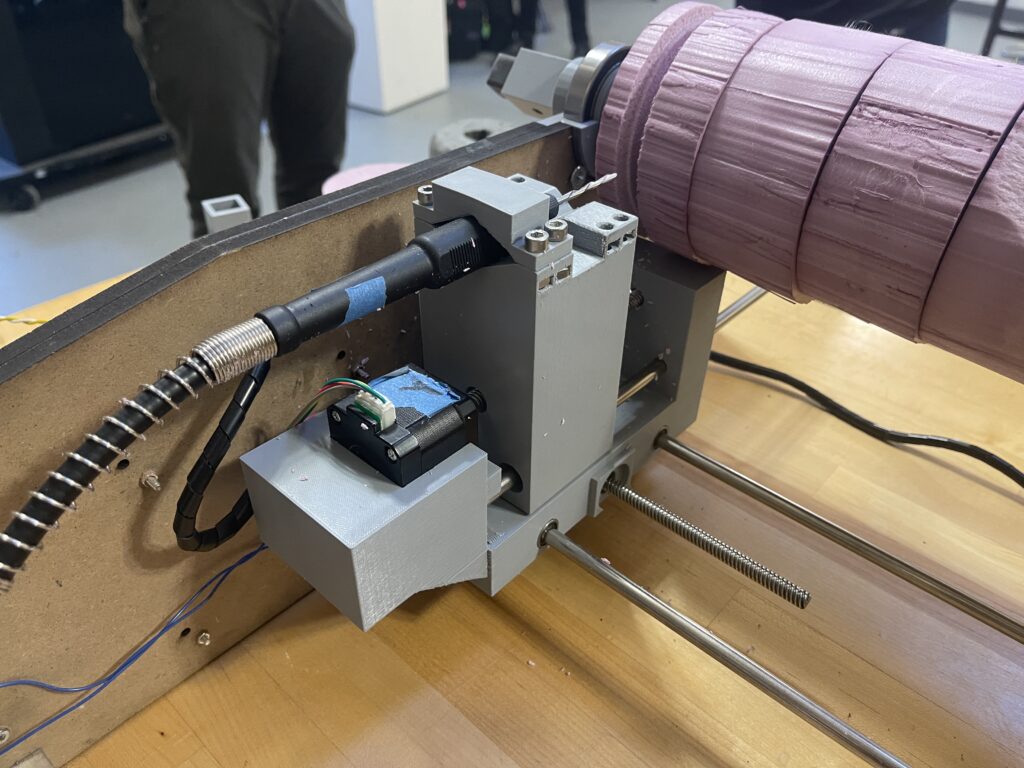

Assembling everything together

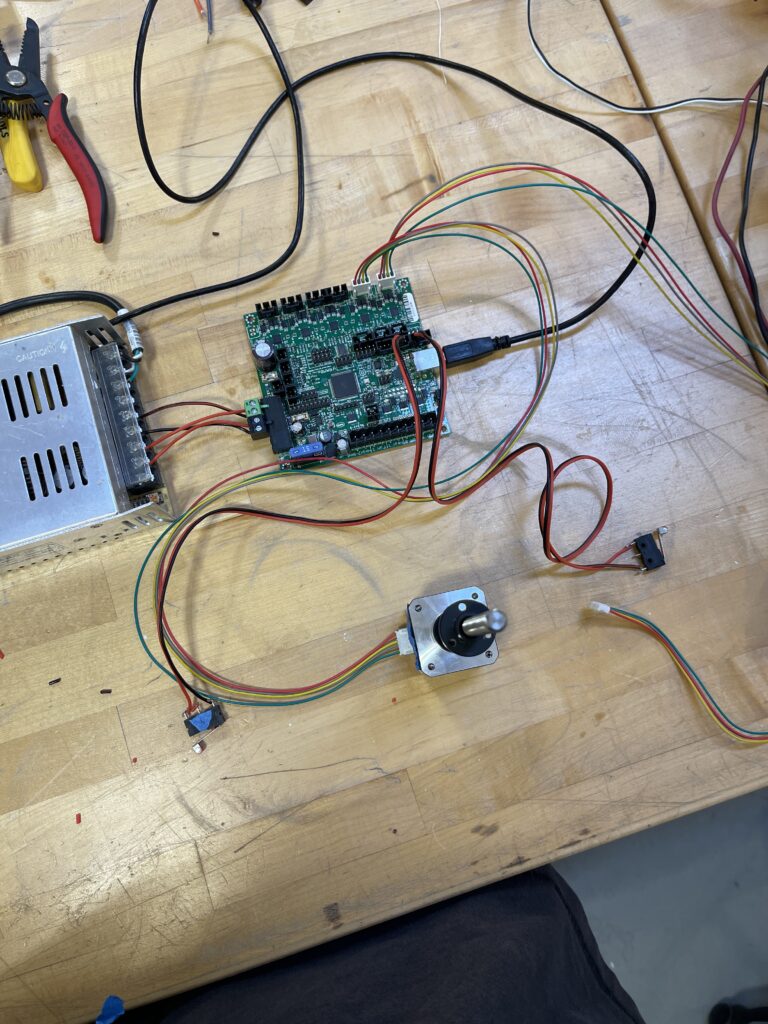

Testing out the the Servo Motors, Board, End stops, Battery and others to ensure the circuit of the machine works.

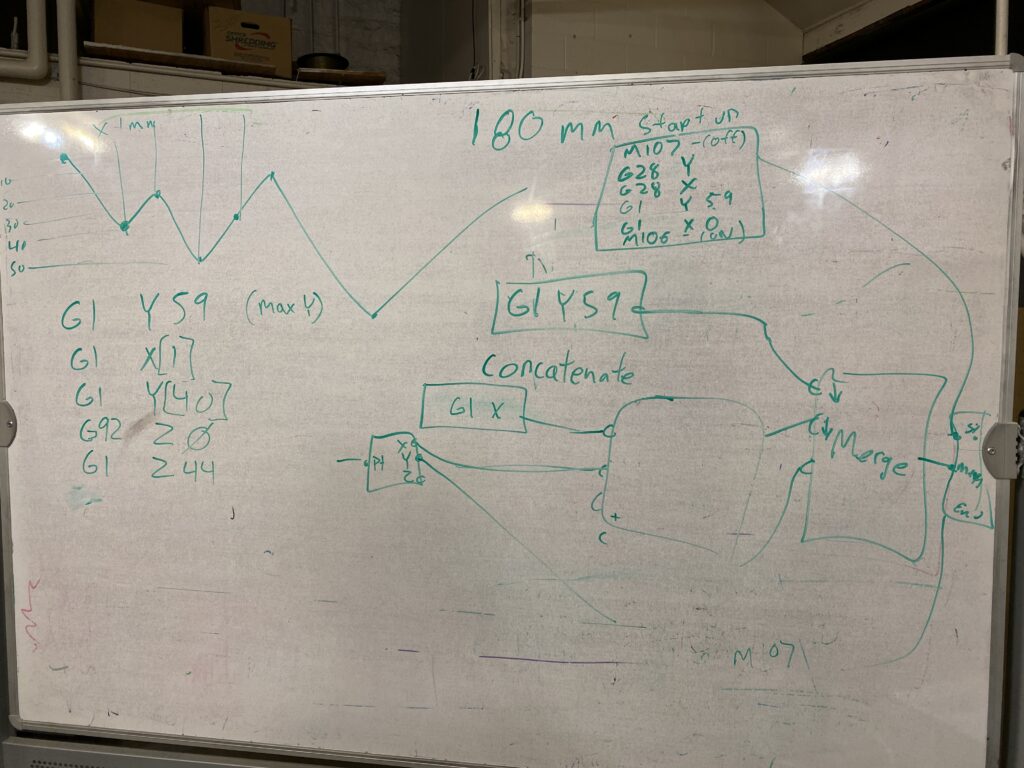

Planning out the workflow of the grasshopper file to give correct instructions using G-Code for the machine to function properly

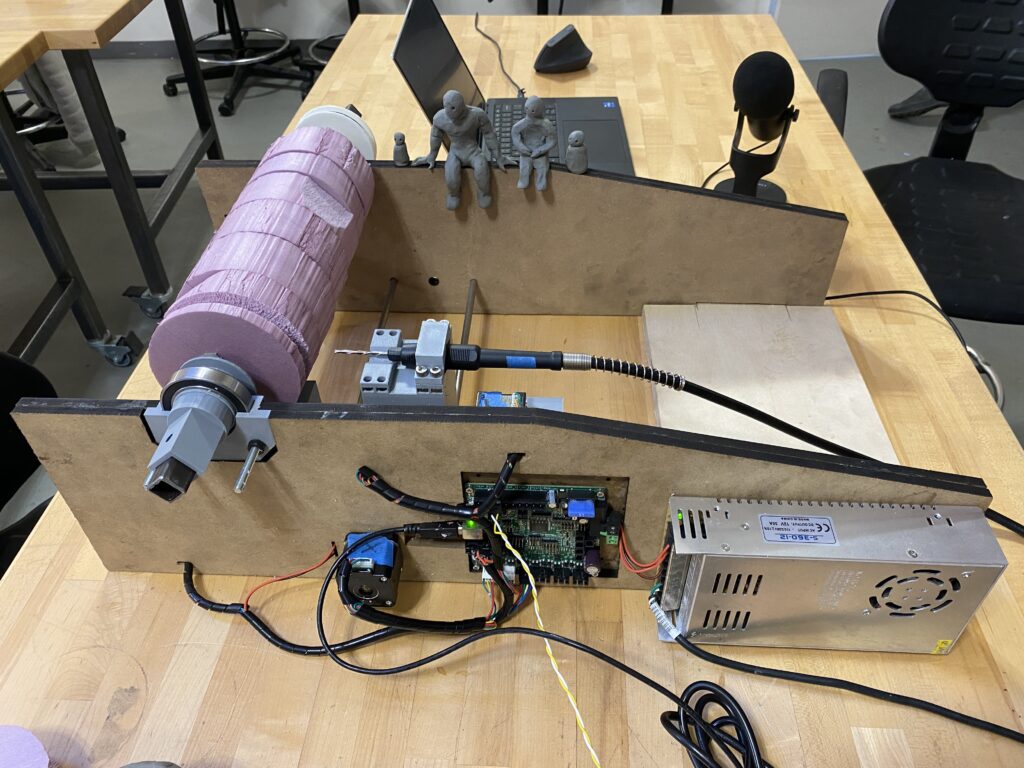

Final Machine (That made it for the crit)

Our final machine we were able to put together for our crit ended up being a machine that milled pink foam. Our GH file ran into a major issue with firefly and only worked the morning of the crit, and our tests with plasticine did not work well. We ended up pivoting to a foam cylinder instead, and our final machine was able to carve the shape generated by our GH file with a decent amount of detail.

Video Documentation

Testing to make sure everything is good to go the night before Critique!

Problems that came up along the making process. Our clay that we were using was too hard and the Dremel was not strong enough.

We got the machine to be able to carve on the clay but the desired outcome was not ideal as the clay’s resistance was creating slug at the edges instead of shaving .

Final Crit D-Day!! Doing final testing and changes with Ryan.

Clay carving in process

Top Down Perspective. Layers of shaving start to take place on the clay.

Changing the material of our project and using Foam instead.

We went to measure the dimensions of the cylinder shape that we needed and laser-cut assisting references from acrylic to guide foam on the foam cutter to achieve our desired shape.

This was the first time we were testing it out on the foam and everybody was on high alert as we did not know if this was going to work.

The foam is working on the machine!! It started carving out neat segments according to the file we had create through grasshopper.

Final Critique: We demonstrated our Grasshopper file that does real-time conversion of sound into 3D generated models in Rhino using the Firefly component using Peng’s music which he played into the microphone.

Final Critique: After getting the sound created 3D Model in Rhino, we convert that data into G-Code so that it can inputted into Pronterface to give instructions for the Machine to wrok!

Final Critique: Dremel at work as it shaves off the first few layers of the foam.

Final Critique: In Progress

Final Critique: There a few setbacks and hiccups along the way of the demonstration but we managed to pull through and demonstrate the capabilities of the machine mechanics and concepts.

Written and Edited by Ian, Kiefer and Ollie