What is 3d printed textile?

3D printed textile refers to the process of using additive manufacturing techniques to create fabric-like structures or objects layer by layer. Unlike traditional textile production methods which involve weaving, knitting, or felting, 3D printing allows for the fabrication of intricate and customizable textile-like materials directly from digital designs.

The concept of 3D printing textiles dates back to the late 20th century when researchers began experimenting with additive manufacturing techniques to create fabric-like structures. These early experiments laid the groundwork for the development of more sophisticated methods.Many industries including manufacturing, aerospace, transportation, the space industry, and construction have extensively explored the use of these methods and widely implemented 3D printing technologies. Most of them have shown promising results in creating a complex form with fewer resources. Moreover, 3D printing also shows its potential in textile manufacture producing fabric that can be used for clothing. While 3D printing is commonly associated with rigid objects, there have been advancements in creating flexible and textile-like structures using 3D printing technology.

Technologies and Materials

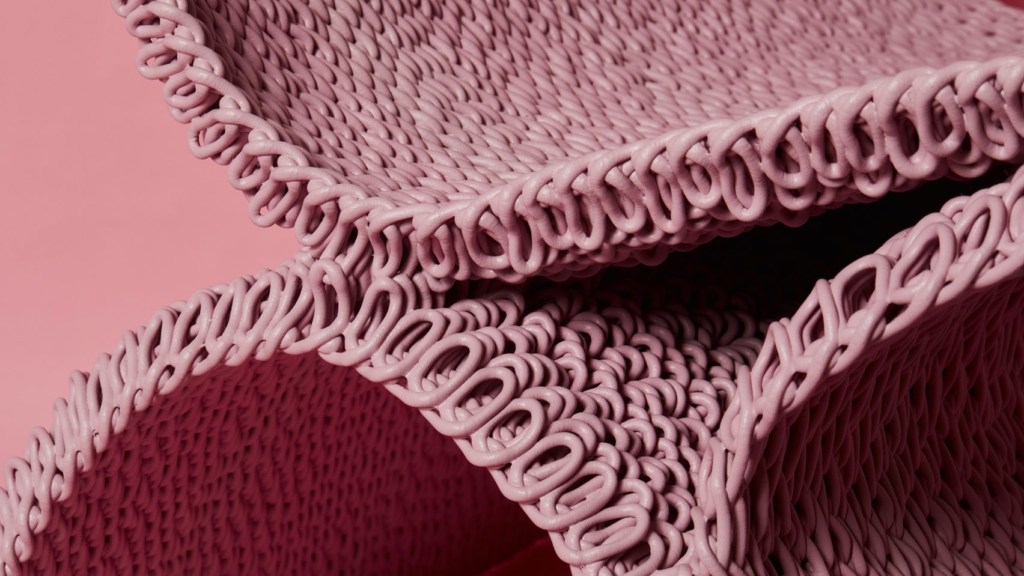

There are many applications of different types of 3d printing methods that can used in making textiles. The most common method is Fused Filament Fabrication (FFF) with flexible filaments like TPU (thermoplastic polyurethane); it makes textile-like objects, like bracelets, phone cases, and even small clothing pieces. The other popular one is Selective Laser Sintering (SLS) technology. It features TPE (thermoplastic elastomer) which is a flexible material, that provides the benefit of strong flexibility and durability. The third one is Multi-material 3D printing which allows for the fabrication of composite structures with varying levels of rigidity and flexibility, echoing the versatility of traditional textiles. Moreover, the frontier of 3D printed fabric-like structures, though not as soft as conventional fabrics, offers a design possibility by mimicking the texture and flexibility of fabric through interconnected fiber patterns.

Also, blending traditional textile techniques with 3D printed components opens up hybrid possibilities, where printed connectors integrate seamlessly with woven or knitted fabrics to create innovative structures. Lastly, in smart textiles, the integration of conductive materials and sensors through 3D printing is also revolutionizing the industry of wearables.

Applications and Current Research Projects

Many research institutions have conducted researches on 3D printing textiles, and looking at how 3D printing and textiles come together. They’re changing how things are usually made, improving materials and designs, and adding smart features. This shift shows that making textiles isn’t just about the old-fashioned ways anymore.

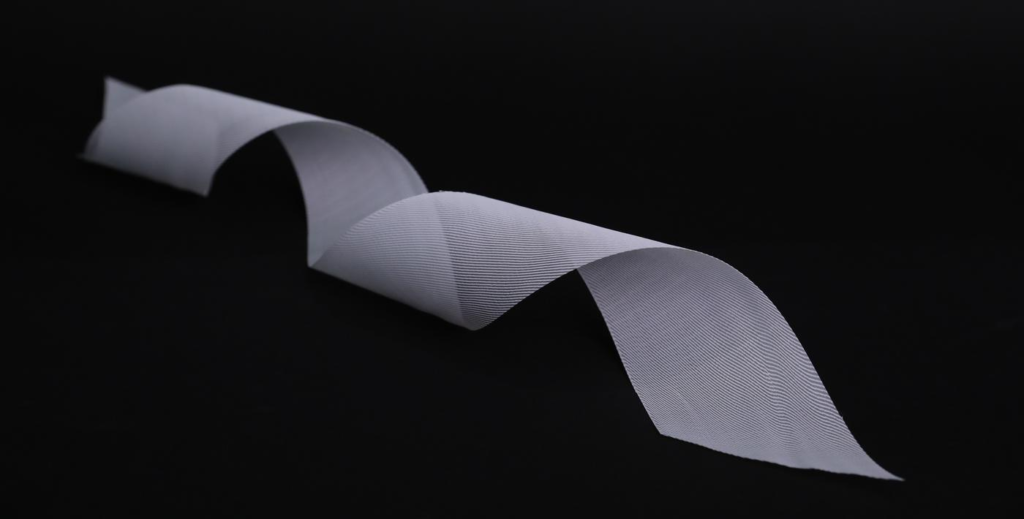

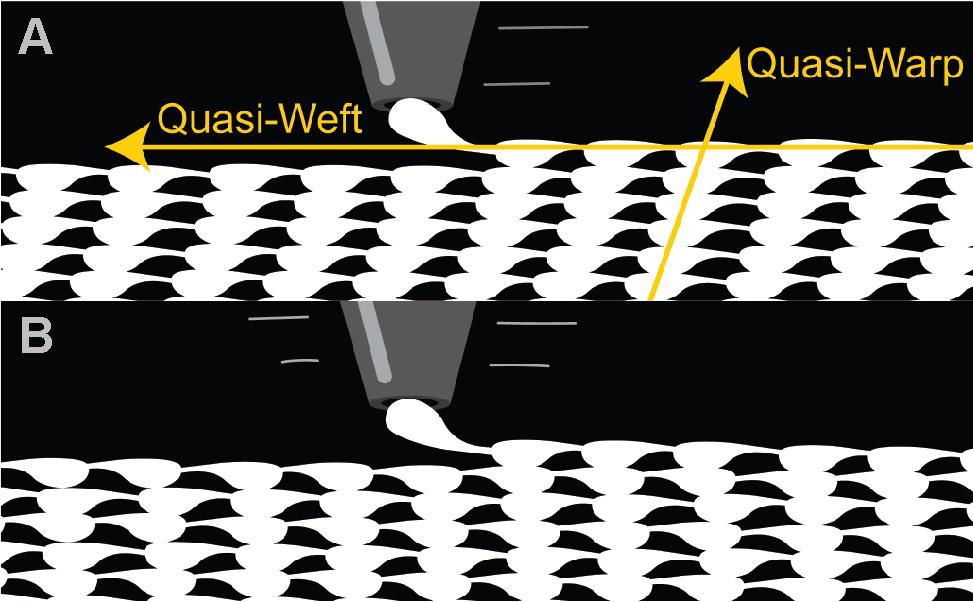

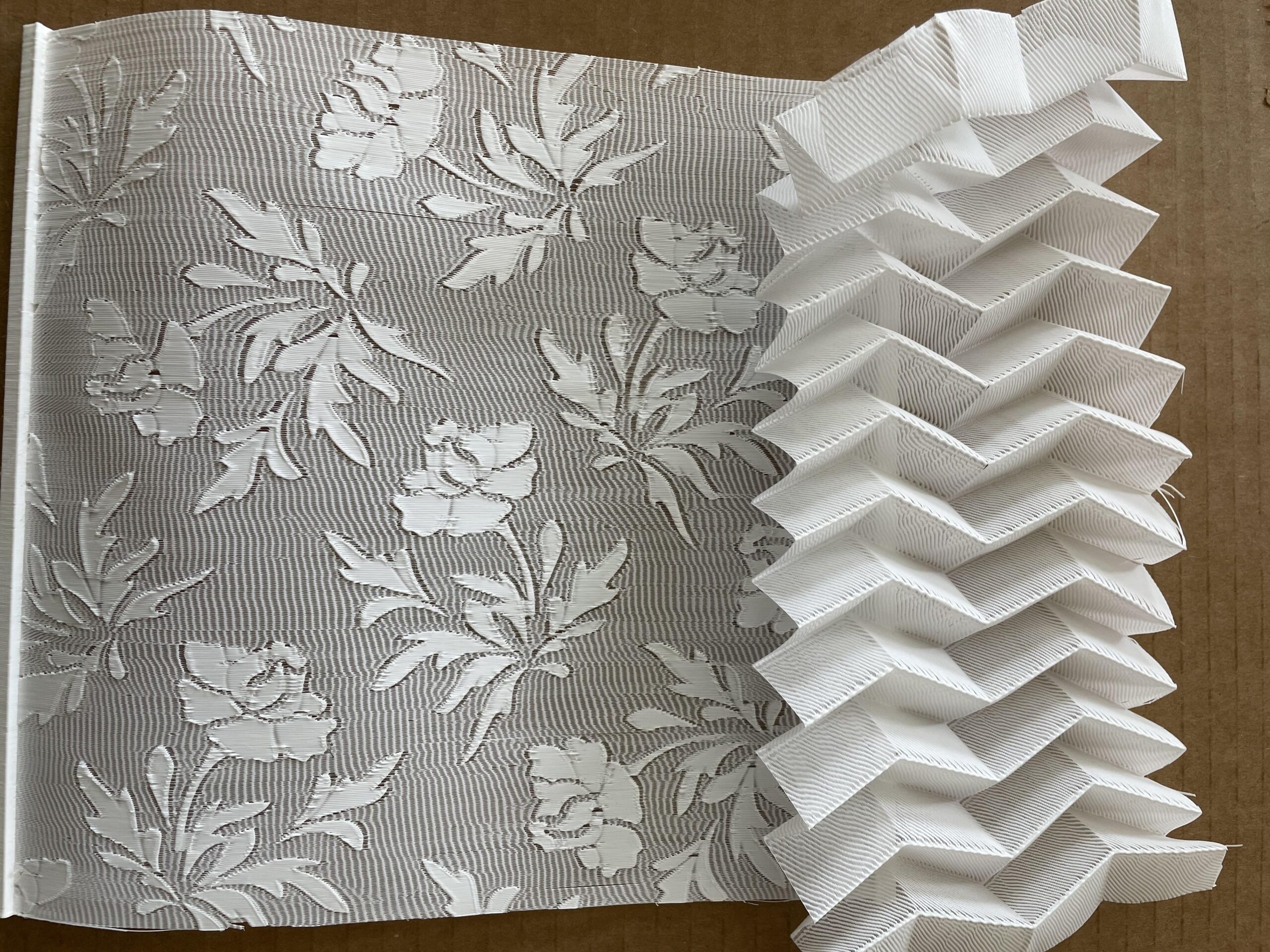

MIT: Soft Fabric

In 2020, 4 students at MIT introduced an ultra-thin 3d printed fabric called DefeXtiles. In their research paper, They show that by utilizing under-extrusion, it’s possible to rapidly print thin, flexible textiles. In particular, as the extrusion multiplier is reduced, there’s a specific range where droplets coalesce, linked by delicate strands, highlighting an optimal condition for efficient fabrication. DefeXtiles are extremely thin, less than .4 mm, meaning they can be densely packed and printed. The fabric is thin and flexible to turn into clothes, lamp covers, and simple attachments like iron-on pockets. Moreover, the fabric can mimic the looks of laces by changing the initial design and codes. With a 3D printer, you can easily design and print your own wearables.

NASA: “Scale Maille”

Inspired by the intricate connections found in ancient chainmail, Scale Maille represents a contemporary interpretation crafted from a single stainless steel sheet. Unlike the medieval designs, this innovative creation is not constrained by welds or rivets; instead, 3D printing technique is employed to extrude the metal, resulting in a sheet adorned with two distinct surfaces.On one side, Scale Maille showcases many interlocking squares, like a mosaic. These squares are polished to achieve a mirror-like finish, providing exceptional heat and light reflection capabilities.

UMD: Heat-Wicking Material

This Heat-Wicking fabric was crafted by the researchers using a specially designed yarn coated with a conductive metal, facilitating enhanced functionality. When exposed to hot and humid environments, the yarn’s fibers contract, activating the coating and altering the fabric’s interaction with infrared radiation, thereby increasing heat absorption. Utilizing a 3D printer, they were able to incorporate a blend of polyvinyl alcohol (PVA) and boron nitride into the yarn during printing, maximizing the thermal conductivity of the resulting product.

Sources:

Foreman, Jack, MIT Media Lab, & United States. (n.d.). Defextiles 3D Printed Lace and Origami Textile [3D printable filament]. Shelf 65. https://jstor.org/stable/community.29904398

Sefar, & Switzerland. (n.d.). Sefar PowerSens Mono with Sefar Carbotex Black Pressure sensor [The PowerSens fabrics are woven fabrics usually consisting of PET and electrically conductive filaments.]. Shelf 52. https://jstor.org/stable/community.29221064

https://www.media.mit.edu/projects/defextiles/overview/

https://www.aatcc.org/aatccnews_06a/