Sam Wilson, Interdisciplinary Sculpture, 2023

Sam is a junior Interdisciplinary Sculpture student primarily focused on furniture design, and is from Houston, Texas. He is interested in creating practical works involving different techniques of wood bending and Japanese joinery with recycled, reused, or environmentally friendly materials. Sam hopes to learn all the 3D modeling skills he can and apply it to his furniture-making toolkit.

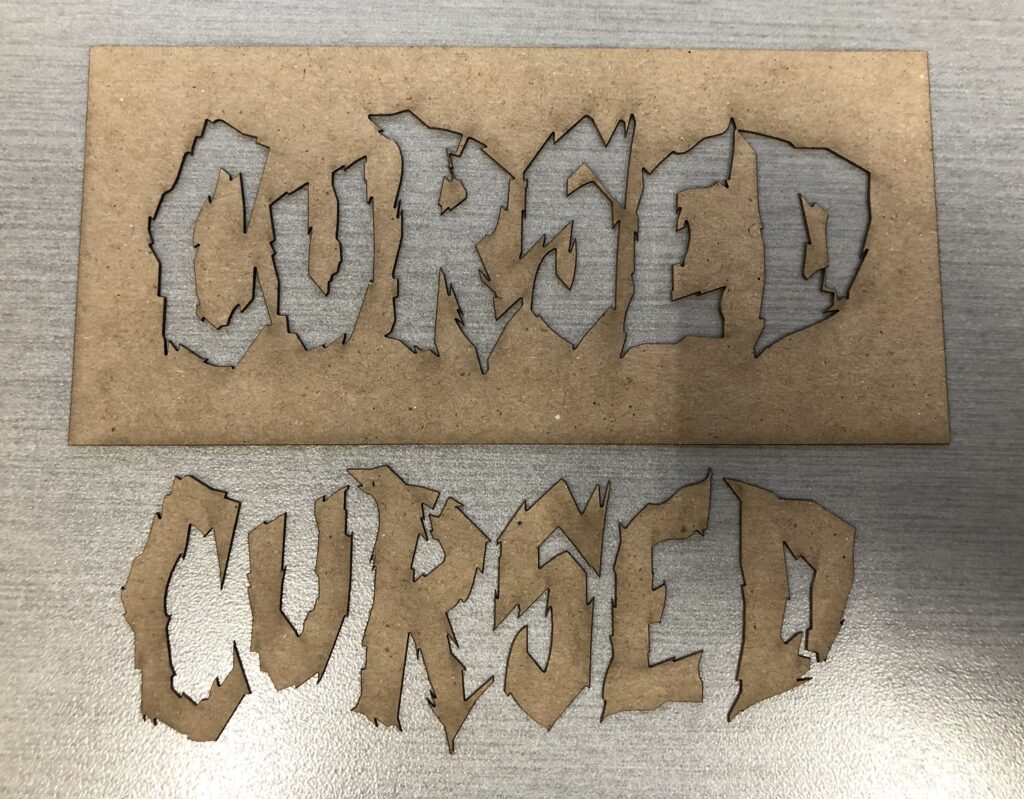

Skill Building

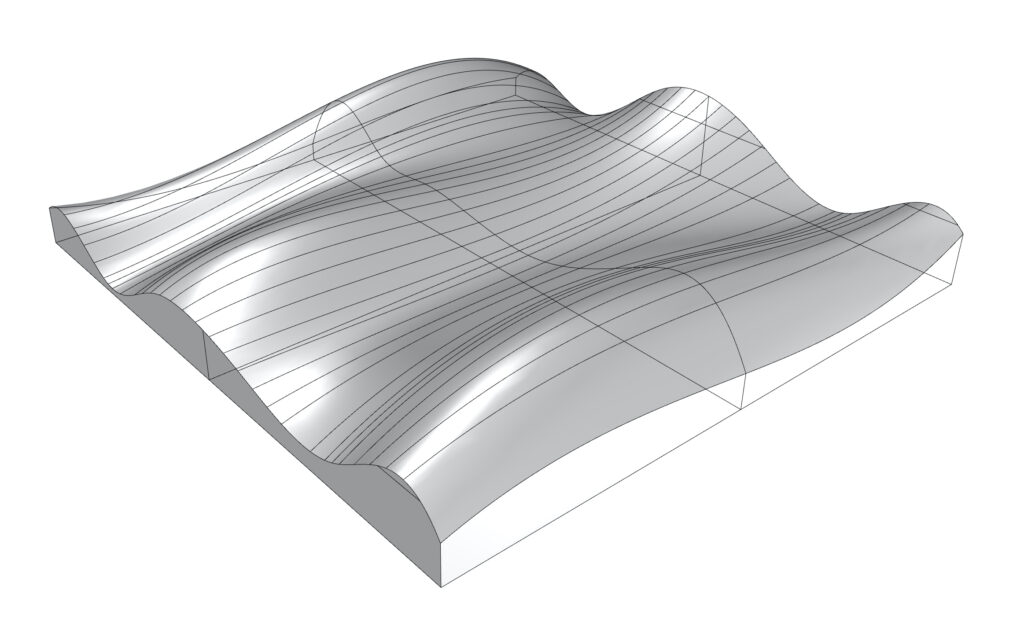

A series of technical exercises build and demonstrate skills in Rhino, laser cutting, 3D printing, and CNC routing.

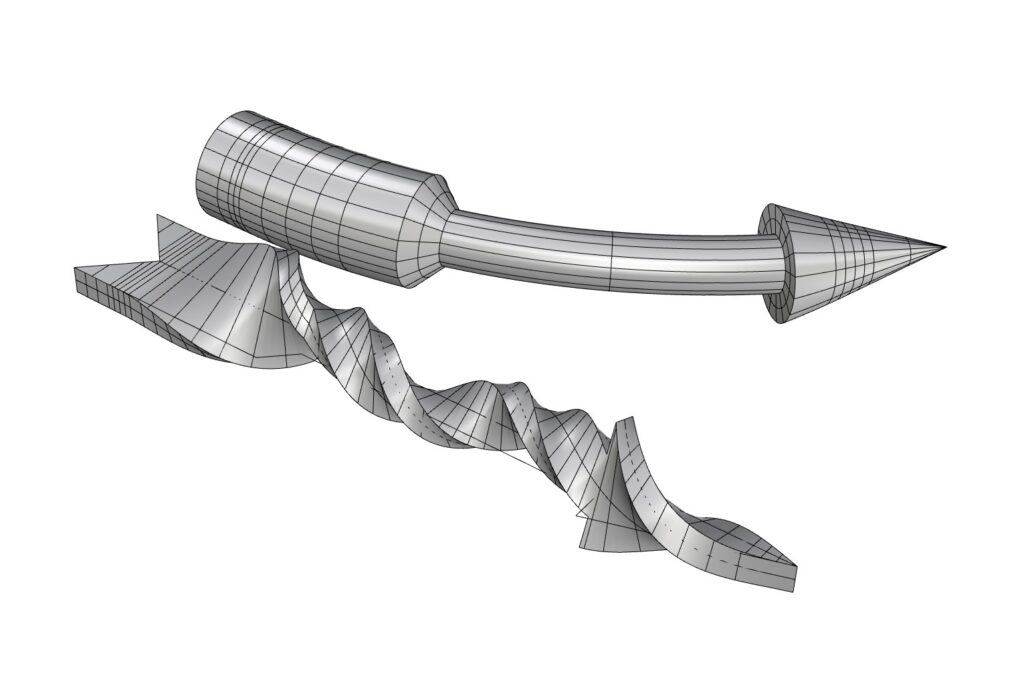

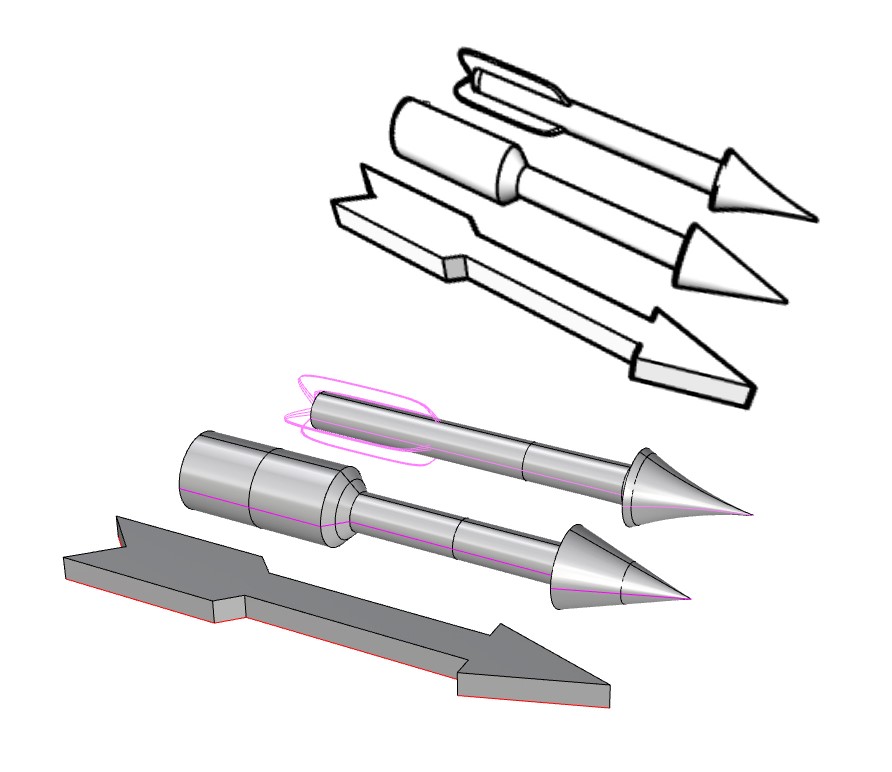

Rhino

files:

https://dfabclass.com/intro/wp-content/uploads/2022/02/22_02_02_Tracing_Word_Numbers.3dm

https://dfabclass.com/intro/wp-content/uploads/2022/02/22_02_02_Tracing_Word_Feast.3dm

https://dfabclass.com/intro/wp-content/uploads/2022/03/Arrow.3dm

https://dfabclass.com/intro/wp-content/uploads/2022/03/Arrow-Options.3dm

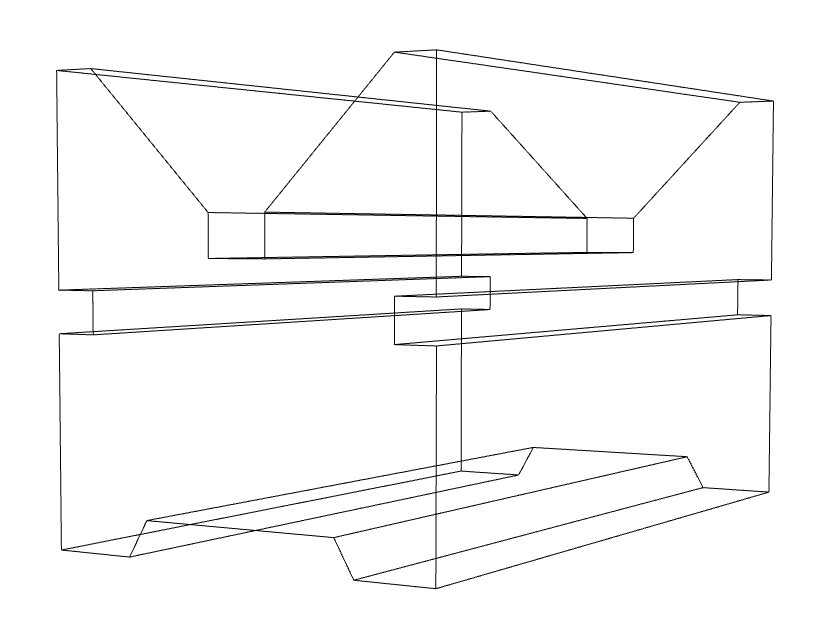

https://dfabclass.com/intro/wp-content/uploads/2022/03/V-Block.3dm

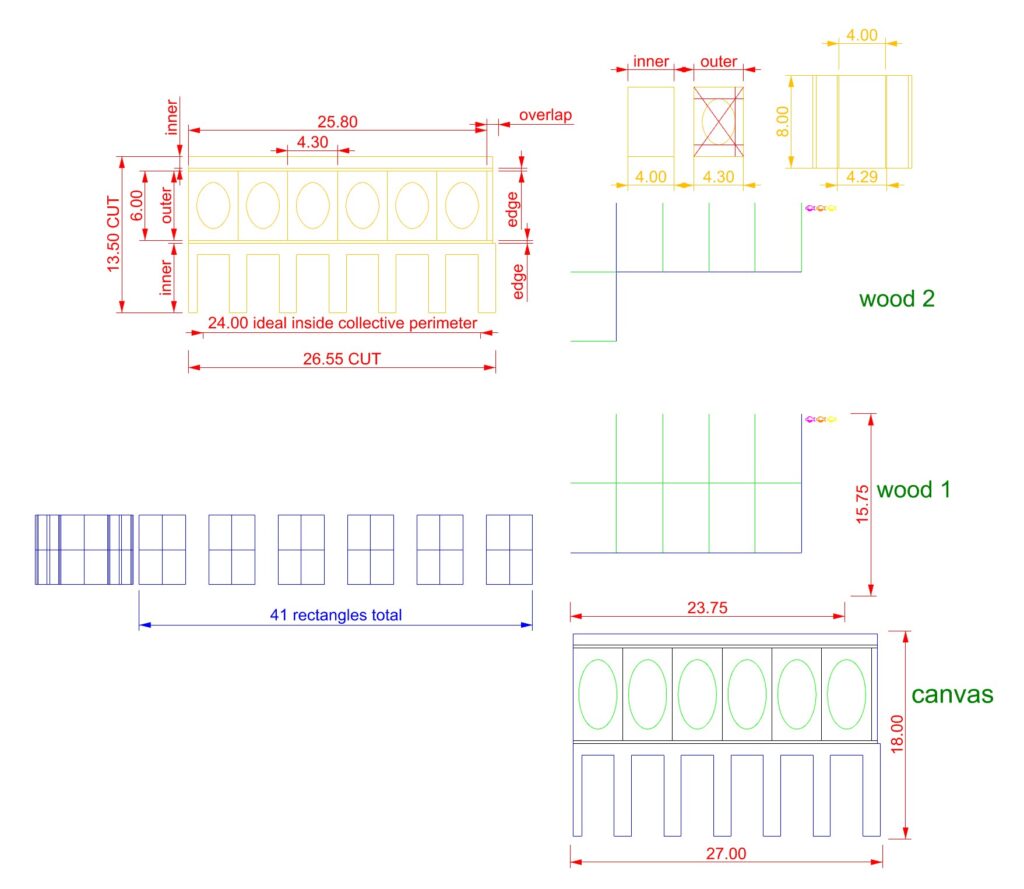

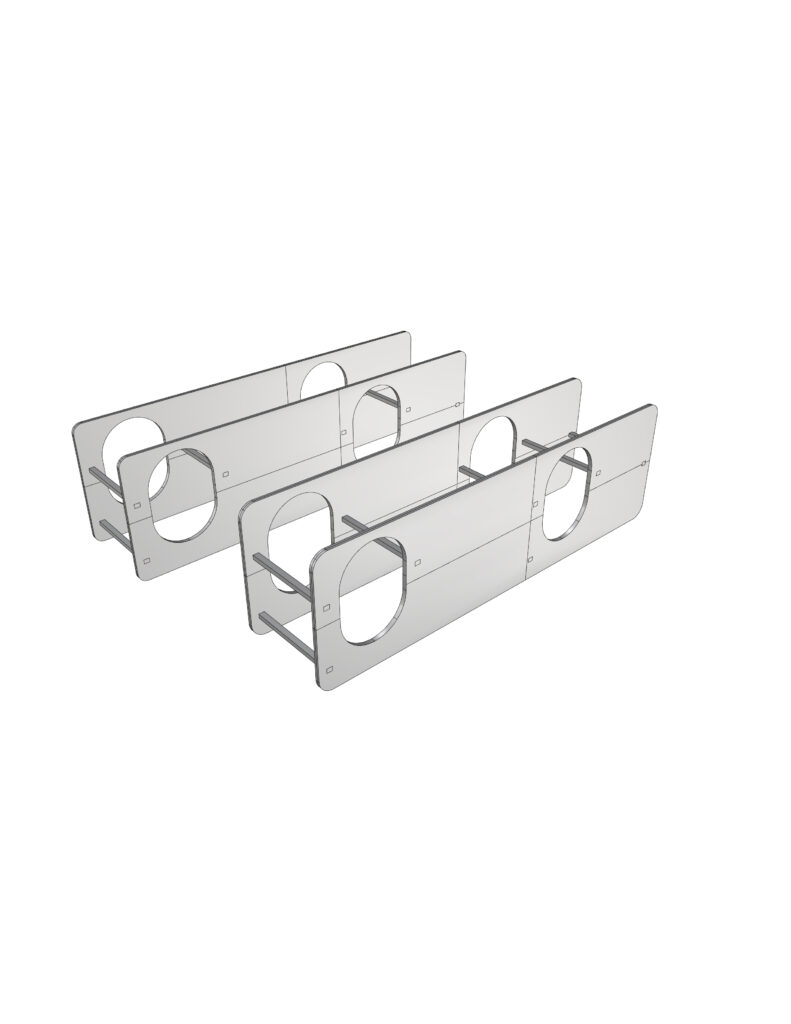

CNC Routing

files:

Project I: Shelves

https://dfabclass.com/intro/wp-content/uploads/2022/03/22_02_10_Project_1_plans.3dm

https://dfabclass.com/intro/wp-content/uploads/2022/03/22_02_23_Project_1_plans_v2.3dm

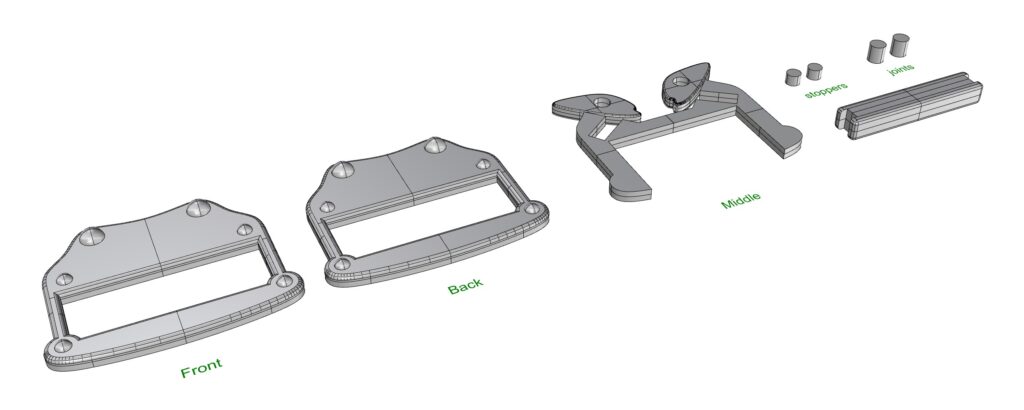

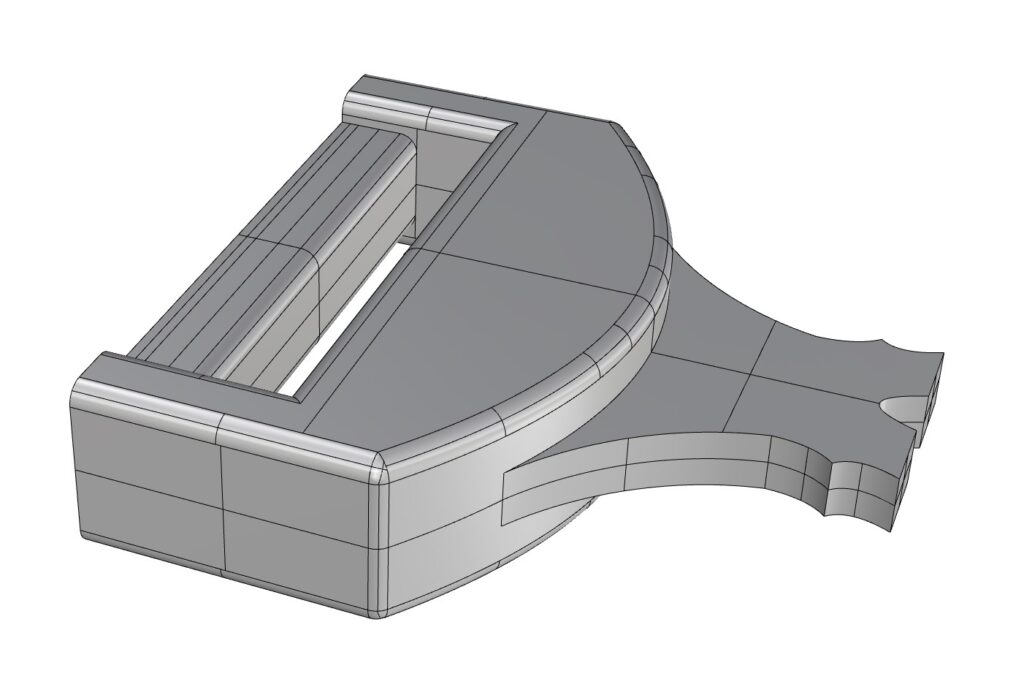

Project II: Tool Bag

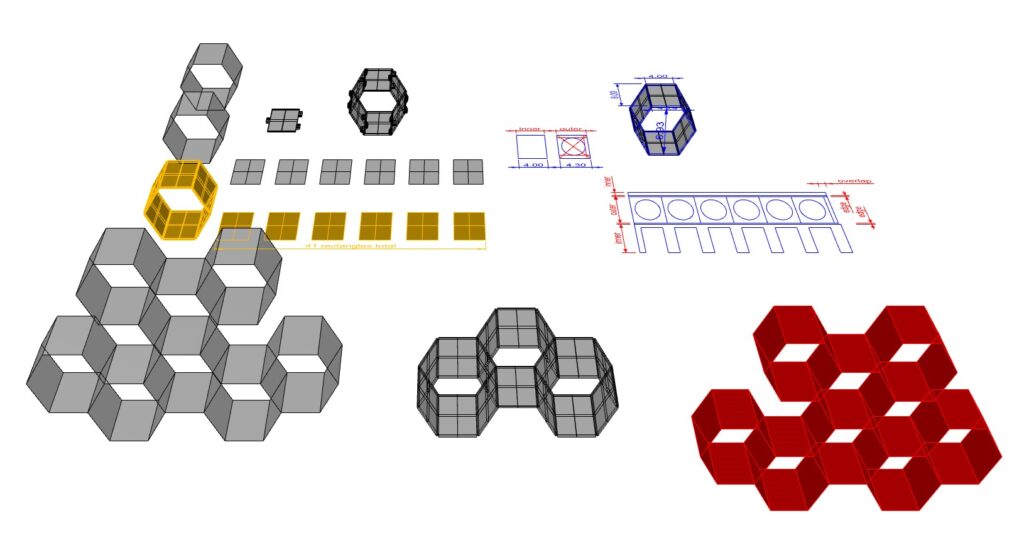

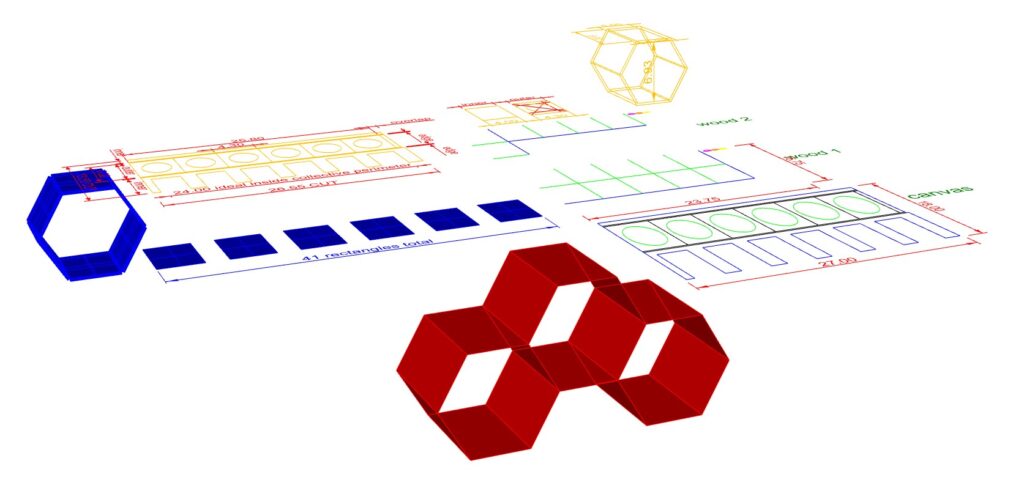

The thought process behind making this was to have a more efficient and organized way to travel with tools and supplies instead of just dumping them in a pile in my backpack. Using spare canvas, elastic, velcro, and zippers I had, I stitched 5 pockets and 7 elastic loops onto a flat sheet of canvas. It is designed to be rolled up and clipped onto the outside of a backpack. The buckle is a modified copy of a belt buckle.

https://dfabclass.com/intro/wp-content/uploads/2022/03/22_03_25_Project-2_buckle.3dm

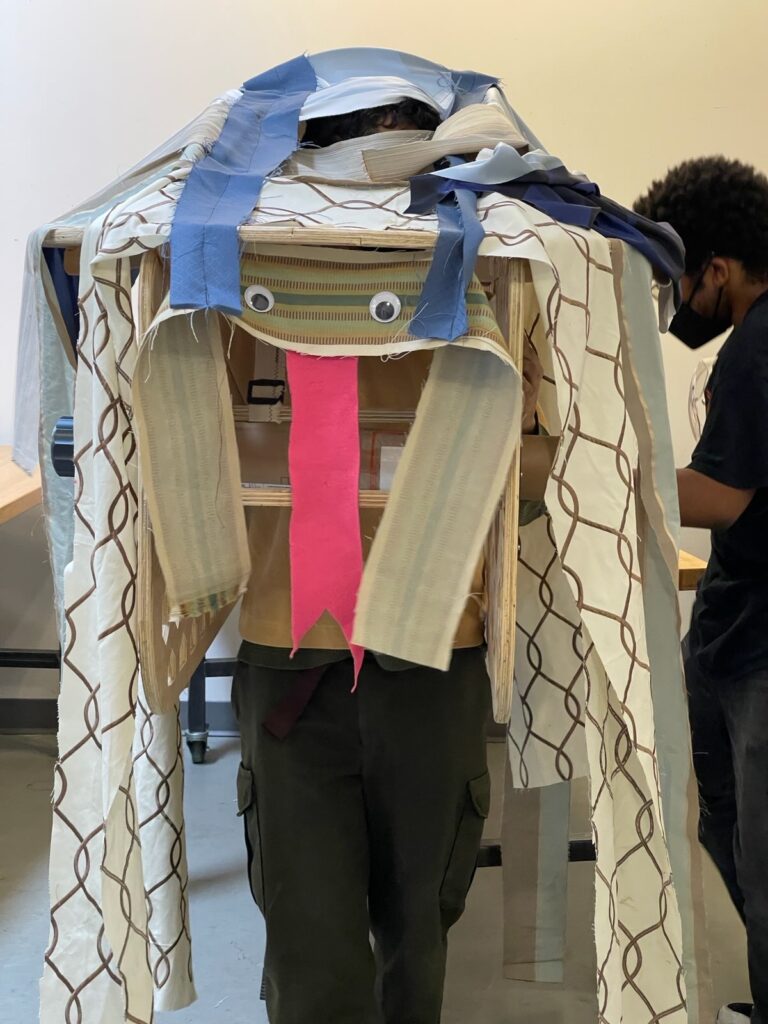

Project III: Caterpillar

As a class, we decided to work on our final project all together dividing the labor to suit our individual skills. We began with splitting into three groups to develop three different chassis designs and later met up again to decide which would work best. We then discussed how the final “look” of it should be, settling on camouflaging the chassis and instruments with a fabric covering. Smaller groups were again formed to develop designs and problem-solve for where the instruments should rest, how the fabric would drape and be secured, how the chassis would be worn, and how we could reduce the weight. The build was not completed until the final day, and after a brief band practice we paraded around campus to entertain other students and visitors.

Process

–

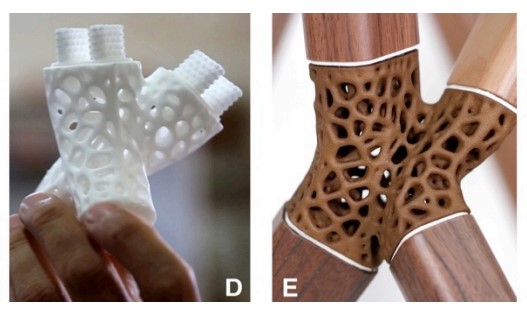

Research: Advances in Joinery from Digital Fabrication

Digital Fabrication has massively improved Joinery in that it offers adaptability, expedites the manufacturing process, and creates a wide variety of new design opportunities. There’s been a resurgence of exposed joinery in the west, especially within furniture design, aided by the practice of digital fabrication. This allows for the development of non-permanent connections where the product can be disassembled if needed, creating an opportunity for modularity. 3D models can also be adjusted between projects to manage its structural integrity and are easy to share and download online. Without machines like CNC routers, Laser cutters, and 3D printers, the capacity of manual tools to create this precise joinery are limited by the maker’s skill and speed. Digitally fabricated joinery has accelerated the trend of exposed joinery in furniture by highlighting it as an intentional part of the design, as opposed to a “seamless” appearance, and by making it look aesthetically pleasing.

https://docs.google.com/presentation/d/1fdoWty4tlB3koh0e8nEBGbI60O63DFqCt0dPx6ljypA/edit?usp=sharing

More Information

additional information and links