Nadia Nazar, Interdisciplinary Sculpture + Animation + MAT, 2024

Nadia Nazar is a 20 year old artist, climate organizer, and musician based in Baltimore, MD. She is an animator and sculptor. Most of her work revolves around her feelings about different systems of oppression and their intersection with the climate crisis and aspects of her identity.

Skill Building

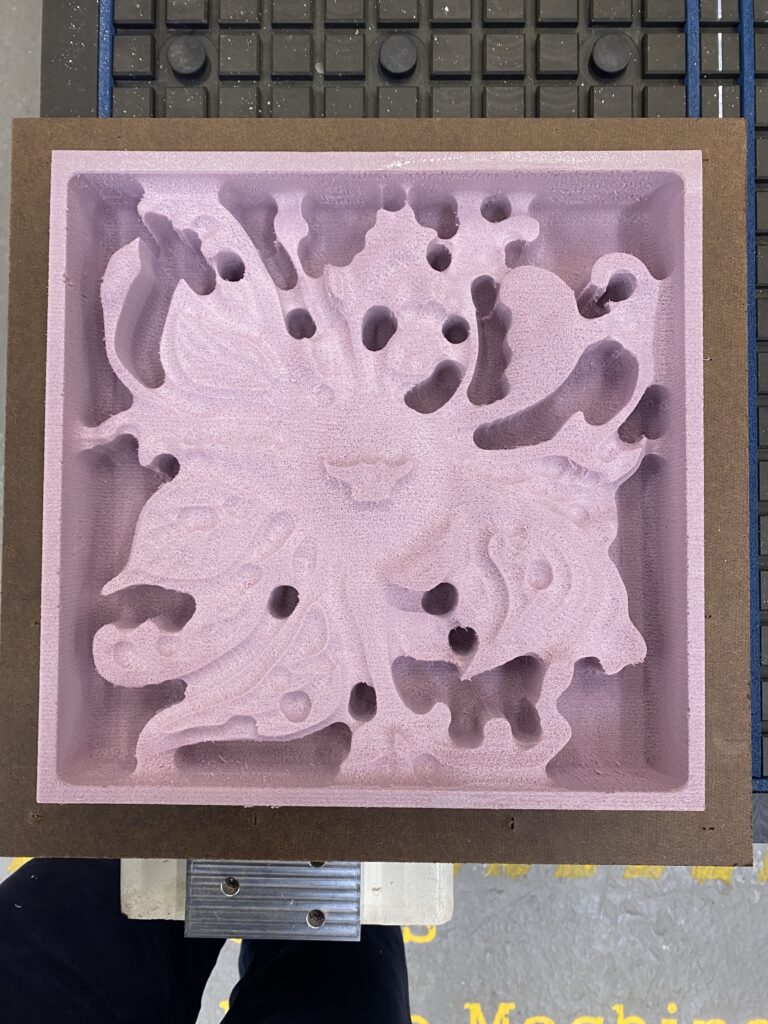

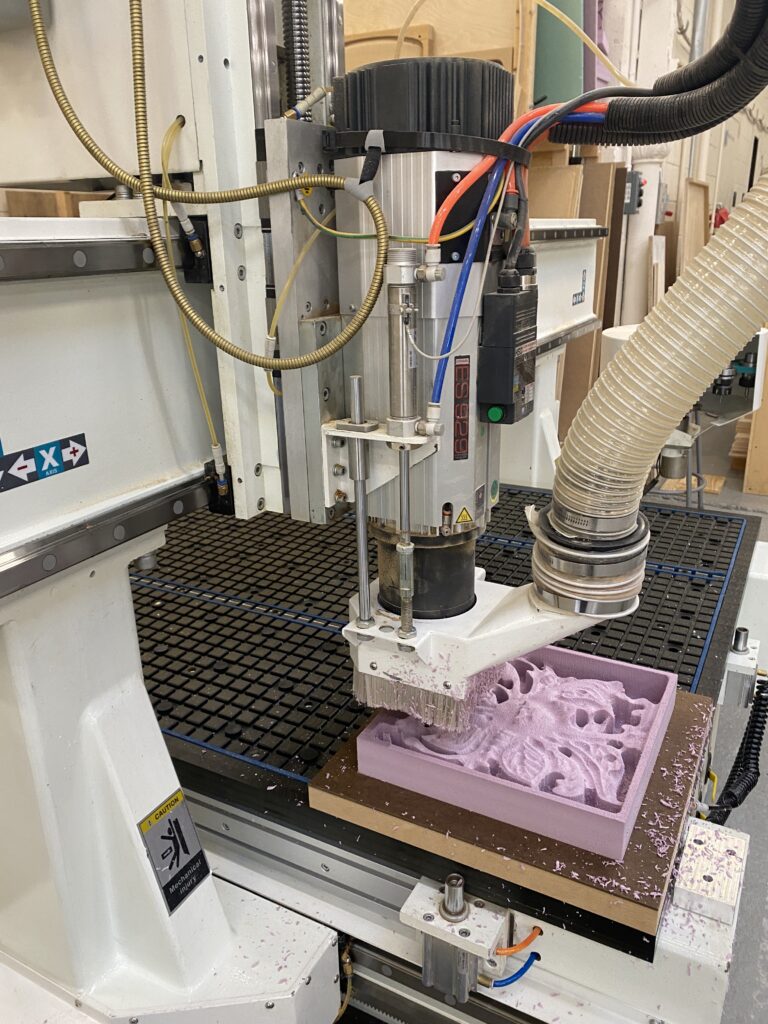

A series of technical exercises build and demonstrate skills in Rhino, laser cutting, 3D printing, and CNC routing.

Rhino

Project I: Kollam

Our memories of places are lasting, unlike the places themselves. The structure in our memories may look the same now as they once did before, but the feelings and the people there can never truly be replicated. I have been longing to touch my homeland for the past few years. Life and the world have kept me from doing so. As I think about my childhood in Kerala, I wonder about the window that my grandma and I cut onions out of, the stray cat I fed milk everyday until we had to bury him, the pile of trash and banana peals outside, the bed that my dad and grandfather slept in, the little daylight that entered the window upstairs, and so much more. I wanted to remember this house, this place through an actual three dimensional visualization. This image I have of this house in my head has been brought to life. And even though it is not an exact replica, it is what lives in my imagination when I think of that place. Sometimes I imagine what it will look like in the future and how the climate crisis may impact it. I think of the houses that have already been torn down from the floods, and how this house may seem.

Project II: Locked

I was experimenting with the assembly of having multiple printed objects connect, especially with differing weights with the steel rings.

Being locked out of a space, often times a space you feel you belong in, feels stretched out. As if the journey to being able to open the door is much longer than it actually is, both in terms of physically opening the door as well as feeling like you belong and can be allowed in a space.

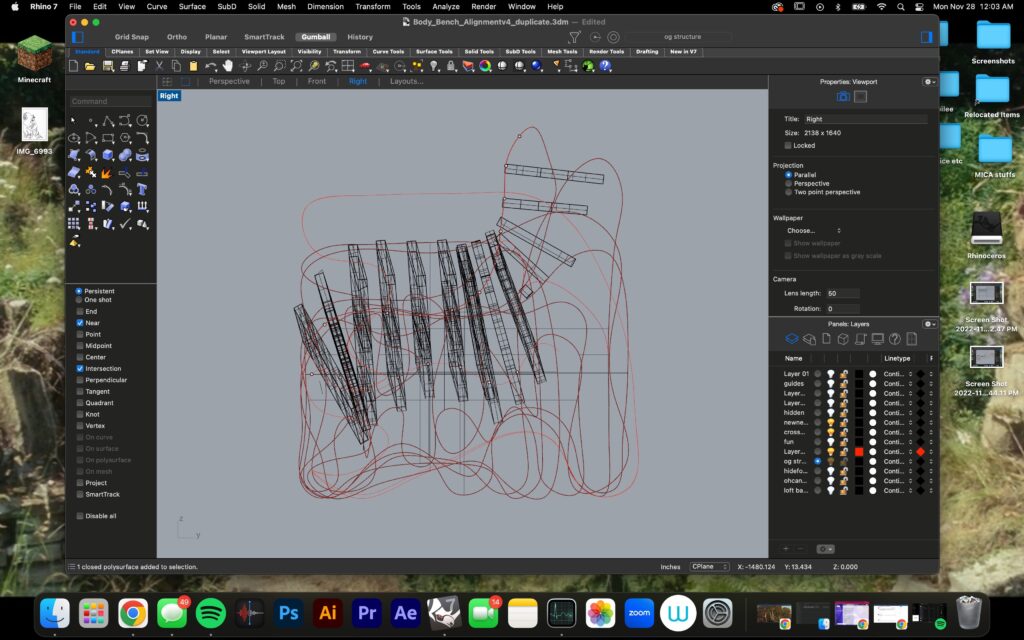

Project III: Body Bench

We wanted to make a site for rest the students of station, who are doing very physically laborious work inside the building. A place to sit, eat with others, lie down, or maybe even nap. This piece was made in collaboration with Liam Davis, Alex Bard, Sean Kim, Jingwen Zhang, and Solomon Wang. We each designed a curve for the bench, that was then combined to create an organic structure for the base of the bench. We used interlocking planes to construct the bench as well. It was milled with plywood and constructed. It is a now sweet spot to sit down for the next few months, and possibly longer.

Process

–

Research

I did Water Based Digital Fabrication for my research project. The presentation is here.

Technology is a significant factor in solutions as we face ongoing environmental issues and problems surrounding waste and mass production. Water Based Digital Fabrication is one of the types of technology that bridges the gap between natural structures in the environment and technology that is being developed currently. We must think about living with the earth and the land as we shift into structures of resilience and adaptation around the climate crisis.

Water Based Digital Fabrication utilized a robotic gantry for 3D printing with biomaterial that is made up with materials derived from water. The project originated in the MIT Media Lab. The biocomposites are made up of chitosan and sodium alginate. Chitin is found in the exoskeletons of different crustaceans, insects, and fungi. This chitin is converted to chitosan through the process of deacetylation. This process is when an acetyl group is removed from the chemical compound. An acetyl group is a small molecule structure that contains two carbon, three hydrogen, and one oxygen atom. The MIT Media lab used shrimpshell specifically as their source of chitosan for this project. Neri Oxman led this project at MIT. She is an artist who combines biology, design, and engineering in her work. She led this project starting in 2013, and is continuing to do work today. One of the major projects was Aguahoja 1. It was a structure five meters tall made of a skin modeled after human skin. Each skinlike structure is called a hoja. The piece was made with cellulose, chitosan, pectin, and calcium carbonate from trees, insect exoskeletons, apples, and bones. This piece was made to react to the environment, adapting to different changes in heat, humidity, and sunlight. It was designed to decay. It is currently installed outside.

Many core values ground the team working with water based digital fabrication. Researchers prioritize decay over disposal. They consider water as a building block for the different structures and parts they are making, especially with how water is used to bring molecules and elements of nature together in wildlife. Some positives include that water is being used rather than petroleum for parts. Parts can decay and return to the earth again, especially not as trash. It is a renewable resource. Pieces can either be chemically stabilized or dissolved in water. The lifespan of what is being made is thought about more and programmed for time based recycling. It takes low amounts of energy and produces little to no waste. They also don’t use toxic materials.

There are so many objects in our day to day lives that we use that don’t need to last forever. We produce so much waste as a society and it has led to massive amounts of trash, and production that pollutes and contributes to much larger environmental issues that impact everyone. Water Based Digital Fabrication isn’t a proper replacement for production on all levels, but it is a start to creating more sustainable objects with a thought out lifespan. This research will help further environmental solutions by other creators. It is important to have solutions that work in conjunction with the environment, adapting and decaying as time passes rather than mass producing objects that are frozen in time for us to only use for a small amount of time.

“Aguahoja.” OXMAN, https://oxman.com/projects/aguahoja. Accessed October 2022.

“Chitin and Chitosan: Production and Application of Versatile Biomedical Nanomaterials.” NCBI, 1 March 2016, https://www.ncbi.nlm.nih.gov/pmc/articles/PMC5094803/. Accessed October 2022.

“Definition of acetyl group – NCI Dictionary of Cancer Terms – NCI.” National Cancer Institute, https://www.cancer.gov/publications/dictionaries/cancer-terms/def/acetyl-group. Accessed October 2022.

Thomas. “MIT develops Aguahoja, programmable water-based biocomposites for digital fabrication.” 3Ders.org, 25 March 2019, https://www.3ders.org/articles/20190325-mit-develops-aguahoja-programmable-water-based-biocomposites-for-digital-fabrication.html. Accessed October 2022.“Water-Based Digital Fabrication video.” OXMAN, https://oxman.com/projects/water-based-digital-fabrication. Accessed October 2022.