Similar to all other 3D printing processes, metal 3D printers build parts by adding material a layer at a time based on a digital 3D design – hence the alternative term “Additive Manufacturing”. This way, parts can be built with geometries that are impossible to manufacture with “traditional” subtractive (CNC machining) or formative (Metal Casting) technologies, and without the need for specialised tooling (for example, a mold). The two most common method used in metal 3d printing is SLM Selective laser melting and DMLS Direct Metal Laser Sintering, and both of these technologies belong to the powder bed fusion category. The two technologies have a lot of similarities: both use a laser to scan and selectively fuse (or melt) the metal powder particles, bonding them together and building a part layer-by-layer. Also, the materials used in both processes are metals that come in a granular form. The differences between SLM and DMLS come down to the fundamentals of the particle bonding process (and also patents): SLM uses metal powders with a single melting temperature and fully melts the particles, while in DMLS the powder is composed of materials with variable melting points that fuse on a molecular level at elevated temperatures. Essentially, SLM produces parts from a single metal, while DMLS produces parts from metal alloys. There are several other 3d printing technologies that can produce metal parts. Two that are rapidly rising at the moment are binder jetting and metal FDM printing.

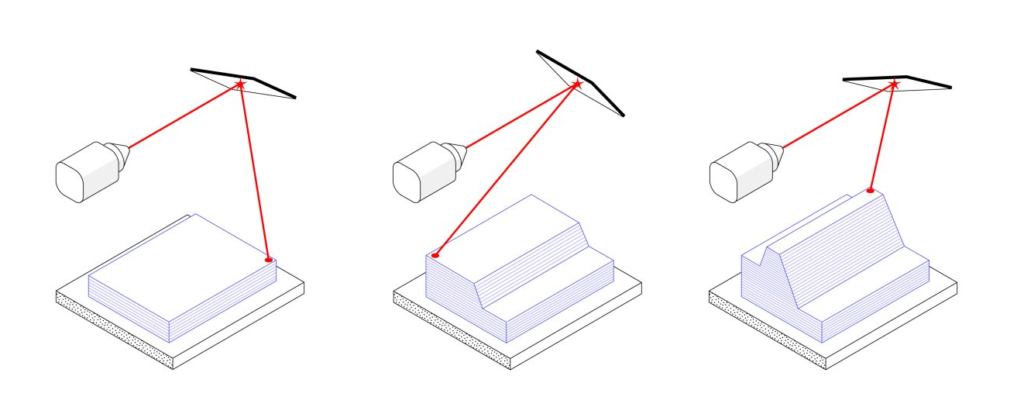

The build chamber is first filled with inert gas (for example argon) to minimise the oxidation of the metal powder and then it is heated to the optimal build temperature. A thin layer of metal powder is spread over the build platform and a high-power laser scans the cross-section of the component, melting (or fusing) the metal particles together and creating the next layer. The entire area of the model is scanned, so the part is built fully solid. When the scanning process is complete, the build platform moves downwards by one layer thickness and the recoater spreads another thin layer of metal powder. The process is repeated until the whole part is complete. After the build process is finished, the parts are fully encased in the metal powder. Unlike the polymer powder bed fusion process, metal 3D prints always require support structures. Support in metal 3D printing is built using the same material as the part and is always required to mitigate the warping and distortion that may occur due to the high processing temperatures. When the bin cools to room temperature, the excess powder is manually removed and the parts are typically heat treated while still attached to the build platform to relieve any residual stresses. Then the components are detached from the build plate via cutting, machining or wire EDM and are ready for use or further post-processing.

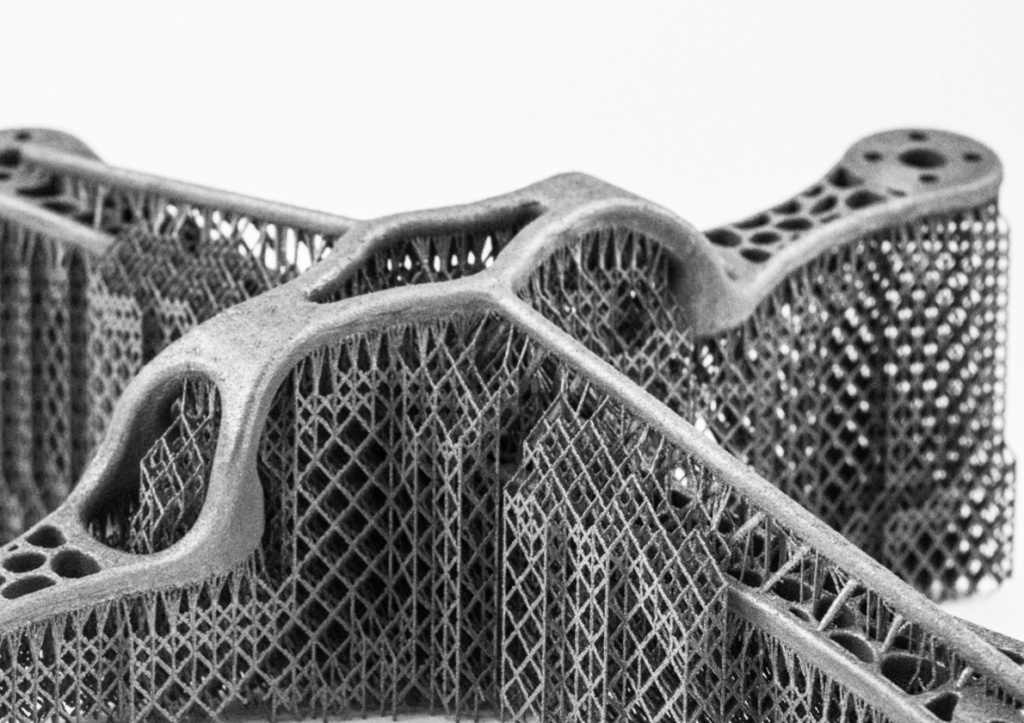

One of the biggest strengths of metal 3d printing is Design freedom. It allows you to print parts that were previously impossible to produce using traditional manufacturing techniques. Two particular areas here metal 3d printing is having a large impact on design freedom is part consolidations. Taking 100 parts and metal printing them to be just a singular piece, and the production of parts with integrated lattice or porous structures, particularly useful in the medical industry or areas with the strength-to-weight ratio is very important. Another advantage of metal printing is metal which has a number of superior properties compared to plastic. And another advantage is that metal 3d printing can produce parts out of titanium and other advanced alloys. Compare to traditional manufacturing technologies like CNC machining the cost of metal 3d printing is high. On average a metal printed part, around the six of our fists, will cost about a thousand dollars to print and finish, with prices rapidly increasing depending on the geometry. Meaning that metal 3d printing is really only going to be justified if you’re going to see a big improvement in performance. Another limitation of metal 3d printing is the build size. The max build size for most metal 3d printers is only 200 millimetres cubed. Metal-printed parts are never ready to use straight off the build platform. Every metal 3d printed part requires some form of post-processing. Such as powder removal, heat treatment or post-machining. And all of this adds to the cost and lead time of production. Metal 3d printing is the most difficult 3d printing technology to design parts for. Just like CNC has undercut and injection modelling has draft angles. There are a set of rules that must be followed to ensure your parts print accurately and successfully, the paper focusing on the support structure. Support structures in metal 3d printing serve 3 different functions. One, It offers a platform for new layers of the print to be built upon, sillier than FDM. Two, because of the temperatures involved, metal 3d printing is particularly prone to distortion and warping. To anchor the parts to the bill’s plate and to help combat warping support structure is often used. And three support structures can act as heat sinks drawing heat away from the part and allowing it to cool more uniformly. Because of the high dependence on support material part orientation is critical when the design for metal 3d print the main goal is always to reduce the dependence on support material as this adds cost and time.

Metal 3d printing has many applications in real life: 1. Functional metal prototypes: Because metal 3D printing requires no tooling and very little machine setup, it offers a way to produce metal prototypes with minimal effort. This allows customers to have accurate metal parts in hand in a matter of days, helping evaluate designs more quickly while avoiding expensive tooling rework. Engineers can explore more designs in a shorter period of time, compressing their product development cycle. 2. End-of-arm tooling: Metal 3D printers can produce conformal end-of-arm tooling much easier and cheaper than traditional methods. 3D printing software automatically generates tool paths, allowing engineers to skip the CAM process. Additionally, the part complexity of conformal grippers introduces no additional cost, so they can be optimally designed to grip parts securely and precisely. 3. Custom tools: While most tools are mass-produced, many situations call for specialized instruments that are manufactured in low volumes. Metal additive manufacturing allows engineers to bypass steep overhead and create custom tools at a low cost per part. 4. Complex bracketry: Metal 3D printing offers an alternative way to create intricate brackets that are difficult or impossible to machine. Thin, complex lattices pose no challenge to the 3D printing process, allowing for the inexpensive production of brackets with specialized geometries. 5. Low-volume end-use parts: Metal additive manufacturing can remedy high part costs for low-volume production. 3D printers make parts without tooling, getting rid of the need to spread overhead across thousands of parts.