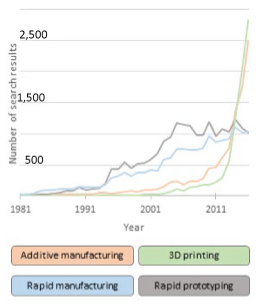

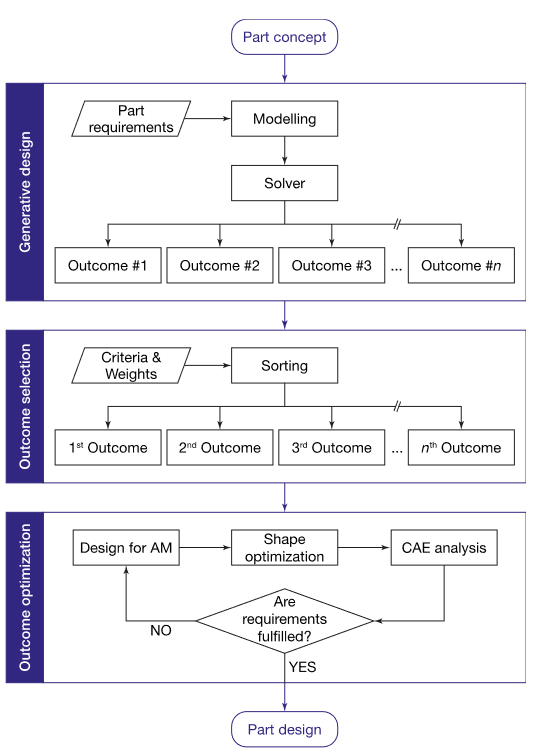

Though additive manufacturing has existed for more than 30 years now, the idea of designing parts and workflows specifically for this process is relatively new. Initially, additive manufacturing was largely limited to “rapid prototyping” of new designs, and as such was more viewed as a means to an end rather than a potential design process in and of itself. Anton Wiberg, Johan Persson and Johan Ölvander of the Linkopings Universitet Tekniska Hogskolan in Sweden identify a number of processes such as topology optimization (TO), which allows designs to be engineered and grown in a more organic fashion according to specific needs and material loads. Generative design (GD) is another process which allows for modeling, prototyping, and gradual improvement of a particular structure via AI tools which automate this process and allow iterations to be created in a far shorter timeframe. Use of these techniques leads to a more efficient use of both materials, space, and weight.

However, with the advantages of additive manufacturing come limitations. A chief limitation of additive manufacturing is the need for supports – build direction and overhangs must be carefully considered to minimize the impact of supports on the material that is to be created. Additionally, despite the best efforts of technologies such as TO and generative design, it is at this point in time difficult to ensure that material strength is uniform throughout a created structure. This can lead to structural failure. Techniques are being developed at the moment to allow additive manufacturing to come into its own as a viable and widespread manufacturing process.

Students at the University of Calabria in Italy used new, partially AI-powered generative design tools alongside traditional processes and older topology optimization techniques in order to create parts for a Formula Student race car, which were then created via Direct Metal Laser Sintering (DMLS) 3D printing. Both parts created via TO and GD represented a significant improvement in both weight and strength over their traditionally designed and machined counterparts. Whether TO or GD was ultimately more appropriate for a part depended on the situation; in some cases, material limitations favored one method over another.

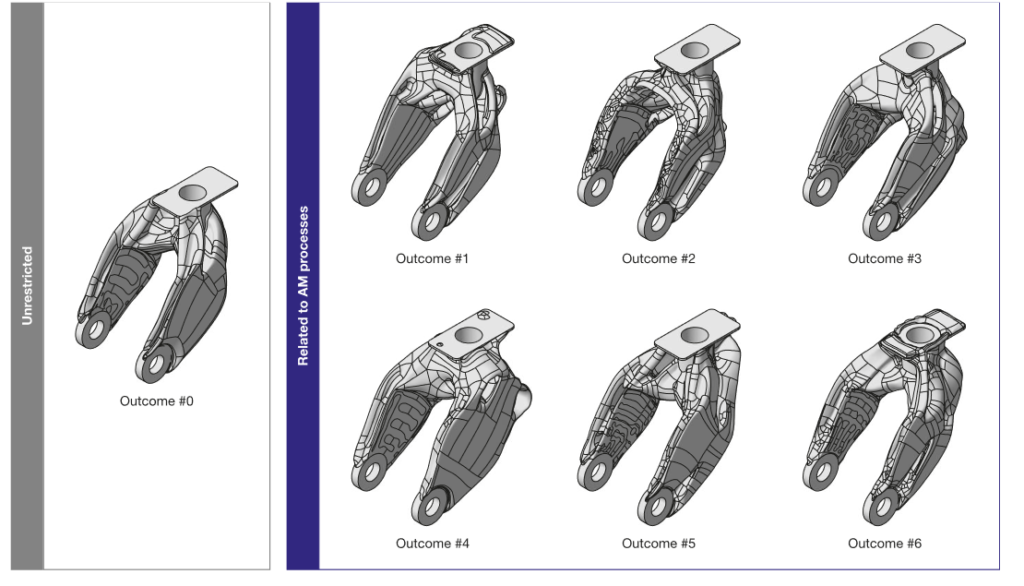

Generative design in particular allows designers significantly more flexibility and efficiency in regards to manufacturing; equally, it allows designers to create structures which would have been unfeasibly time-consuming to model by hand. Researchers at the Politecnico di Torino in Italy used generative design software to develop a replacement landing gear support for a light aircraft. The resulting part was lighter and used less material than the original; additionally, it consolidated a structure that would have been constructed of several smaller components into one component created via additive manufacturing.

Addressing some of the shortcomings of additive manufacturing, researchers at the University of Sheffield in the UK have been experimenting with recreating the natural crystalline structure of metals within lattice-like internal structures possible with additive manufacturing in order to boost strength and enhance plasticity in materials created using this process. By incorporating elements of metallurgy, CAD, and additive manufacturing, they were able to create an integrated process that yielded objects and materials of superior strength and quality to more traditional CAD designing. This overcomes a chief limitation of current additive manufacturing techniques: a potential lack of strength or failure points created by variations in the material created by the process. Material analysis and specialization within the context of additive manufacturing is a relatively recent phenomena and as such represents a future that, alongside digital design and material creation methods such as topology optimization and generative design, allows for the creation and effective manufacture of structures which would have been impossible to manufacture, far more inefficient, or too difficult to design.

In short, design for attentive manufacturing is an emerging field which builds upon existing technologies of CAD and 3D printing, incorporating deep study of material properties and manufacturing processes, as well as new AI tools and software, in order to create a design process that strives to optimize the possibilities of 3D printing to create novel, often otherworldly-appearing solutions to problems both technical and everyday, as well as methods to manufacture these parts in an integrated and holistic process.