Amazing material work and individualized craft are attributes that are sought after in furniture. Everyone wants a durable piece to last a lifetime that accentuates their style and pulls their space together. But in the fast-paced world of today, it is difficult to support traditional craft and give artists, designers, and craftspeople the true time and money deserved for a product since they are in demand and used pretty instantaneously, especially furniture. Digital fabrication is beneficial to furniture design because of its accessibility and various applications for every kind of designer, craftsperson, and artist.

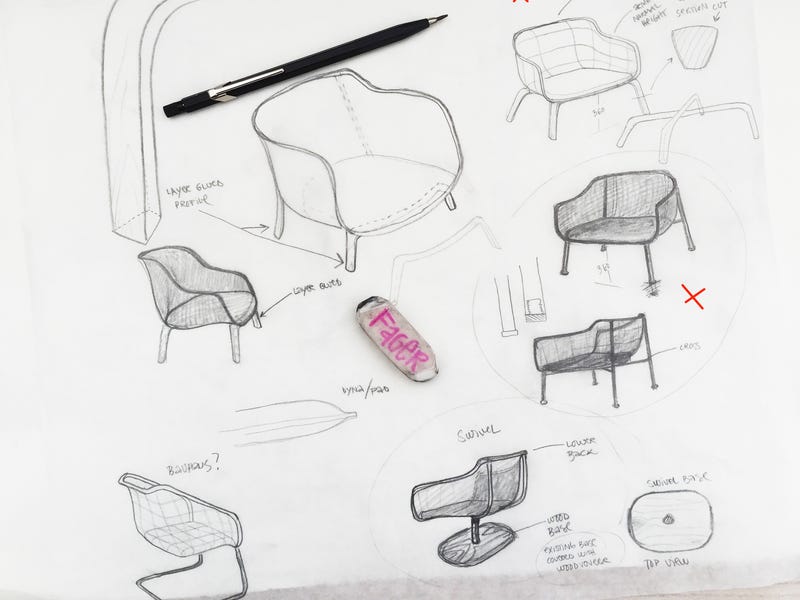

Digital fabrication and translation are huge game-changers for art and the production of entrepreneurs and craft businesses. The change from hand tools and human error has opened opportunities to extremely precise designs that allow for material sustainability, quick and easy replication, and the ability to combine science and art in unique ways. Cad Crowd, a service for companies to commission freelance CAD artists, states these benefits of CAD modelling in their blog article “How 3D Modeling Can Cut Costs in the Furniture Market”.(8) Although a bias article aiming to get consumers to use their service, this source makes some good points about the uses of 3-D modelling, rendering, and the use of digital fabrication in furniture design. Entrepreneurs or companies that use CAD modelling and rendering are able to minimize their material use in the design process since the accuracy and visual appeal of digital modelling make up for a physical model that takes up storage space and wastes materials and resources in the iterative design process.(8) And having a rendered 3-D design eliminates the need for long and laborious photo shoots for promotional imagery.(8) Take Ikea, for example. Their design processes and catalogs revolve around digital fabrication. For quick prototyping, they utilize 3-D modelling and 3-D printing, and their catalog imagery is all comprised of rendered 3-D models instead of photographs.(1) All of this implemented digital fabrication saves time and money by allowing the designers to efficiently communicate with suppliers as well as eliminate the time, resources, and effort that documentation photos take.

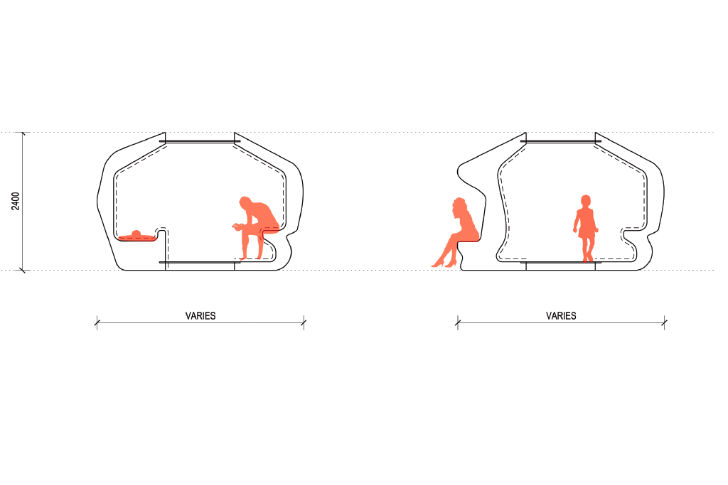

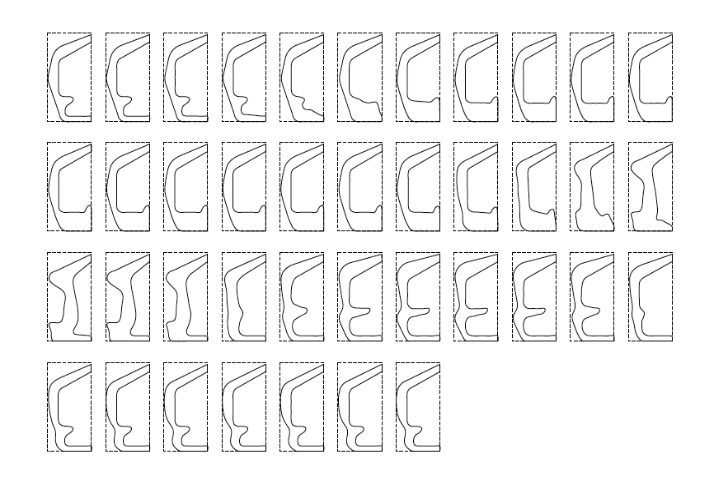

Digital fabrication is so much more than just CAD modelling and prototyping. These processes can lead all the way up to the finished product of a design through CNC machinery. The use of completed files and CNC milling or cutting gives designers and craftspeople the opportunity to duplicate their product repeatedly with ease. This process also aids sliceform and flatpack designs, which are great for expanding the target demographic of a product or piece since flatpacking makes shipping more efficient, and sliceform figures require simple construction, likely without tools. A great example of these sliceform and flatpack designs are the BVN Architecture emergency shelters. Fabricated from laser-cut plywood, these shelters are easily flatpacked for shipping and only take one to two people to assemble without tools due to their sliceform notches that rids the structure of loose, confusing hardware.(5) Designed and produced to take advantage of the quick and accessible nature of laser cutting, the shelter is an efficient solution to unpredictable disaster sites.

In a similar vein to the BVN Architecture emergency shelters, Architecture Global Aid used extensive modeling and digital fabrication processes to create origami-inspired house shelters for tsunami disasters in Tokyo, which are made out of a buoyant wood, and earthquake disasters in Spain, which are made from affordable paperboard.(6/7) These houses double as tables when they are folded up and not in use so that the shelters are accessible right on the disaster site instead of having to wait for temporary shelters to be shipped and assembled.(6) These house pieces are laser cut and assembled in a flat-folding style for easy transport and storage, yet they only take three minutes to unfold and assemble.(7) Without digital fabrication, these shelters would be very difficult to produce quickly by hand due to their precise joinery and multi-functions.

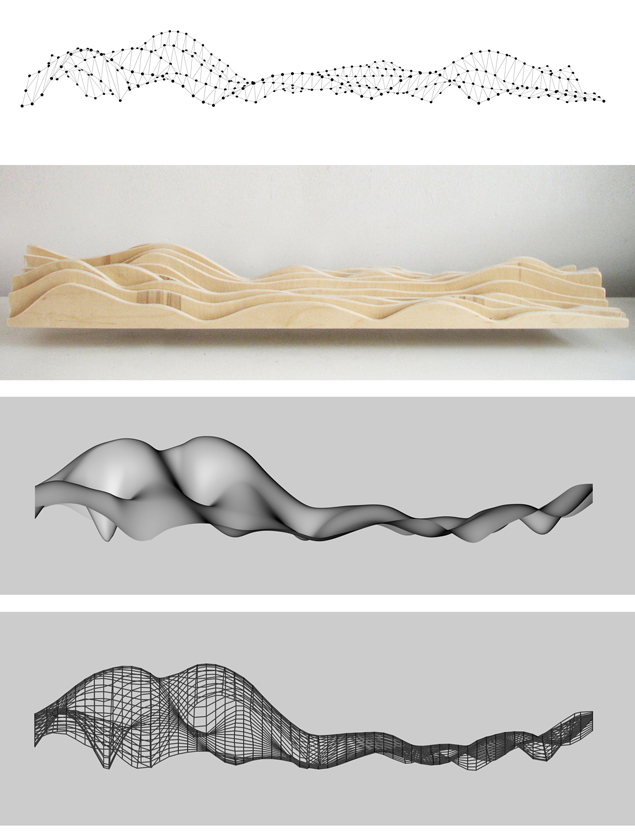

Digital fabrication in furniture does not always have to be such a literal design process for a utilitarian product. Some contemporary artists use digital fabrication as a part of their concept. Lucas Maassen, an artist who explores functional, everyday objects in fictional ways, seized the opportunity of digital fabrication making imaginary forms reality in his “Brainwave Sofa”. Maassen used EEG brainwave technology to scan his brain’s Alpha activity for translating into futuristic furniture.(4) This EEG file was instantly translated and sent to a CNC milling machine, where soft foam was milled into the waves taken from the scan.(4) The foam landscape was later surfaced with felt and upholstery buttons as refinement and finishing.(4) Maassen’s ability to create this piece with reading technology and the translation of waves into three-dimensional form as well as the digitized milling process to precisely replicate the reading gave him the opportunity to speak on future production processes. His concept for this piece was an imaginative form of what design production could turn into in the future: a computer reading the brain and instantly producing the artist’s idea.

Maassen shows his digital process to achieving this sofa by documenting each of the digital translations: the points made from his EEG scan, the translation of those points to a mesh, the mesh formed into a surface, and finally the 3D modeled surface CNC milled into foam. (4)

Digital fabrication in furniture is useful among all different processes and applications. Designers take advantage of CAD modelling speed, versatility, and ease as well as scale model 3-D printing. Entrepreneurs and production businesses rely on the precision, flexibility, and replication of CNC machinery. Contemporary artists make good use of the expansive imagination, translation, and analogue impossibilities that come from combining digital information and data with digital fabrication to make a tangible form that tantalizes and intrigues their audience. Accessibility of digital fabrication methods and processes to various kinds of artists, designers, craftspeople, and problem-solvers has enhanced furniture-making for the makers as well as for the consumers through efficiency and exploration.

Bibliography

(1) Baer, Drake. “A Top Ikea Designer Reveals How to Make Furniture for the Masses.” Business Insider, Business Insider, 11 Jan. 2016, www.businessinsider.com/inside-the-ikea-design-process-2016-1#when-i-develop-products-i-usually-do-some-quick-hand-sketches-to-understand-the-project-she-says-and-shows-them-to-her-team-7.

(2) Barni, Andrea francesco & Corti, Donatella & Pedrazzoli, Paolo & Rovere, Diego. (2018). A Digital Fabrication Infrastructure Enabling Distributed Design and Production of Custom Furniture. 10.1007/978-3-319-77556-2_11.

(3) Lorenzo, E., and C. Lorenzo. “On active learning and sharing through digital fabrication.” ICERI 17 Proceedings, IATED Academy, Spain (2017).

(4) Maassen, Lucas. “Brainwave Sofa.” Lucas Maassen, 2009, www.lucasmaassen.nl/projects/index.php?4.

(5) Meinhold, Bridgette. “BVN Architecture Unveils 3D Puzzle Emergency Shelter at Melbourne Exhibition.” Inhabitat Green Design Innovation Architecture Green Building, 10 May 2013, inhabitat.com/bvn-architecture-creates-a-3d-puzzle-emergency-shelter-for-a-melbourne-exhibition/.

(6) Peters, Adele. “These Origami-Inspired Houses Pop Up In Disasters.” Fast Company, Fast Company, 8 May 2014, www.fastcompany.com/90455787/jonathan-adler-tan-france-recharge-on-the-road.

(7) Stott, Rory. “Origami Houses: Tables That Become Shelters When Disaster Strikes.” ArchDaily, ArchDaily, 18 Apr. 2014, www.archdaily.com/497839/origami-houses-tables-that-become-shelters-when-disaster-strikes.

(8) Wentz, Cathy. “How 3D Modeling Can Cut Costs in the Furniture Market.” Cad Crowd, 27 Nov. 2018, www.cadcrowd.com/blog/how-3d-modeling-can-cut-costs-in-the-furniture-market/.