As the world has technologically advanced over the course of history, the CNC milling machine cannot be understated as the most important development in computerized manufacturing. Starting with the invention of the lathe in 1300 BC by the ancient Egyptians, humans have always used machines as tools to ensure a standard of perfection and reproducibility, but the introduction of computerized instructions overhauled the ways in which products were both assembled and produced. Without machinists and their ability to perfectly manufacture the components that run the world around us, the production of every good, from children’s toys to the industrial facilities that create them, would become drastically more complex. This begs the question: who was responsible for the shift to CNC technology, and what was the response of those who had their jobs automated?

The history of the CNC milling industry starts with the U.S. Air Force and John Parsons, an inventor and engineer working for Sikorsky Aircrafts, to create a system that would allow for faster manufacturing of helicopter parts [1]. After hiring Frank Stulen, who earned an aeronautical engineering degree at the Carnegie Institute of Technology, Stulen created a system of 17 points, mapped for and read by a punch card reader, to mill out the parts more quickly. With Parsons’ input, the system was eventually expanded to use 200 points, helping to combat any inconsistencies caused by the previously limited number. Despite the new invention working as intended, the time spent milling the parts was replaced by the efforts to enter the punches, inspiring Parsons’ to continue working on a fully automated milling machine. In 1949, after securing a $200,000 dollar contract funding his research by the U.S. Air Force, servo engineers from MIT would be hired to continue development. However, the budget would run out before Parsons could see the full development of the CNC, and the project would be handed off to MIT for further development [2]. From there, MIT would collaborate with Richard Kegg, who worked at The Cincinnati Milling Machine Company, to develop the NC, or Numerical Controlled machine [3]. The Cincinnati Milacron Hydrote would become the first commercially available NC milling machine in 1952. The NC would also replace the original punch cards with a seven track punch tape, and NC machines would prove to reduce costs and improve the quality of the milled parts. Still, the time spent creating the punch tapes did not offset the efforts to mill the parts, and further developments would be made [4].

The development of the Whirlwind Naval Computer by MIT would help to create a new system for mapping the coordinates of the CNC router. John Runyon, part of the MIT engineering team, would use the Whirlwind to create a coding system that would drastically reduce the time spent programming the toolpaths of the machine, shortening an eight hour job into a fifteen minute one. From there, the CNC would only be improved with the ATP, or Automatically Programed Tool, by Douglas Ross and J. Francis Reinties, allowing the computer to understand the complex toolpaths needed to create the necessary parts. From there, the usage of the CNC would explode into all types of manufacturing industries, and further computer-based developments would be made, such as the introduction of CAD (Computer Aided Design) and CAM (Computer Aided Machining) technologies to allow machinists to easily map out their parts [5].

These changes did not come without pushback from traditional machinists who manually operated their mills using a high degree of learned precision, and traditionally skilled machinists are still essential for the production of milled parts today [6]. While CNC operated mills are better suited for creating mass produced parts for commercial use, traditional milling skills serve to aid in the prototyping process, often used as an early step in designing parts that can later be CNC milled [6]. Manual milling should also be considered an artform that takes years of training in order to create parts that are accurate down to the micrometer, and the craftsmanship necessary to achieve this level of precision cannot be understated.

The importance of machinist work, both computerized and manual, for the development of new technologies across the world is clear. From its origins in the U.S. Air Force to the availability of small CNC and other milling machines for personal use, machinists are right to take pride in their incredibly complex skillset.

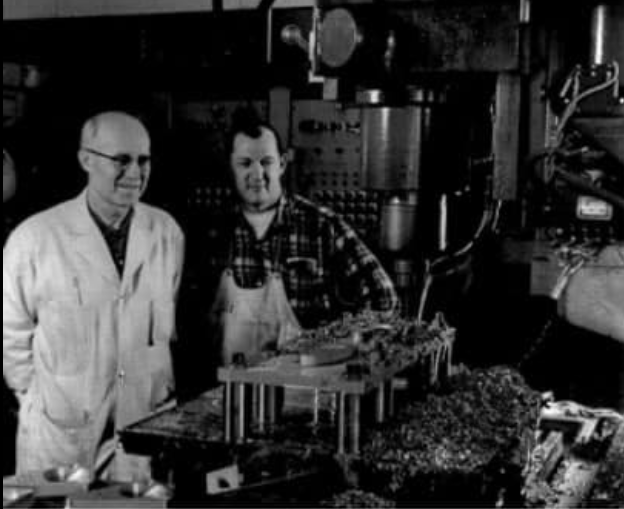

For a more personal grasp on the history of machinist work, I interviewed James Groer, the CEO of Dragonfly R&D and a lifelong machinist. Starting from the age of eleven, James was employed by his father, a machine shop teacher in Oakland, Maryland, to assist in his own machine shop, where they would tap holes into metal rods for military use. His job was to clean up the finished parts, filing off sharp burrs and ensuring everything was up to military specification. Despite the shop being a two (and a half) man operation between James’ father and a friend, the work they did was part of incredibly important military pursuits such as the Mercury and Gemini space capsules.

James studied at the Naval Ordnance Laboratory in White Oak, Maryland, participating in one of the last machinist apprenticeship programs in the area. After his schooling was over , he founded Dragonfly R&D, for which the first tools he bought were a three-axis Lagun milling machine and an IBM Compaq Deskpro 386. From his home shop, he has primarily designed and produced high quality medical devices for neuroscience research, commissioned by institutions such as Walter Reed National Military Medical Center. Although he retired in 1997, he continues to operate his business today, giving him over fifty years experience as a machinist working with CNC mills.

Ever since he was a child, it was James’ destiny to fall in love with the art of machining. Whether it be meticulously measuring and hand milling parts or writing g-codes directly on his Lagun machine, he described his life as a machinist as ‘a lot of fun,’ inspiring words to those who are intimidated by the idea of being in the shop. As his daughter, a fact I neglected to mention, I can certainly attest to his joy. He pridefully introduces me to the machines in our basement every time I visit my home town, eager to teach me how to operate them now that I understand what they can do. We barely go a day without excitedly showing each other our new designs and ideas, wondering just what we can make in our basement, which doubles as both a small prototyping facility and a place to do laundry. Although I originally sought to study illustration in college, I could not be happier with my switch to product design, which has allowed me to both understand and appreciate the importance of my father’s shop, the work he does, and the work I will be able to do in the future with the knowledge of how to use CNC machines.

Sources:

[1] “The Evolved History of CNC Machining”, James Engineering. https://www.james-engineering.com/history-of-cnc

[2] “The Unique History of CNC Machining ft. Mickey Mouse | The History of Machining,” James Engineering, 2024. https://www.youtube.com/watch?v=i-PwGfXjIkk

[3] “The History of CNC Machining,” AMFG, 2023. https://amfg.ai/2023/10/26/the-history-of-cnc-machining/

[4] “The Unique History of CNC Machining ft. Mickey Mouse | The History of Machining,” James Engineering, 2024. https://www.youtube.com/watch?v=i-PwGfXjIkk

[5] “The Integral Role of Machinists: A Brief History and Their Modern Relevance,” ISC Manufacturing. https://iscmfg.com/the-integral-role-of-machinists-a-brief-history-and-their-modern-relevance/

[6] “The History of Machining,” TITANS of CNC MACHINING, 2023. https://www.youtube.com/watch?v=NVe8Xi0pr2M

[7] “CNC Machining vs Manual Machining Process: How to Choose the Right One?”, Zintilon, 2023. https://www.zintilon.com/blog/cnc-machining-vs-manual-machining/