Name, Major, Graduation Year

Alex Bard, Interdisciplinary Fine Art, Mt. Royal grad program. 2023. Born and raised in Philadelphia. Studied interdisciplinary fine art in undergrad. work for an architectural metal company for three years. Now enrolled in Mt. royal graduate program

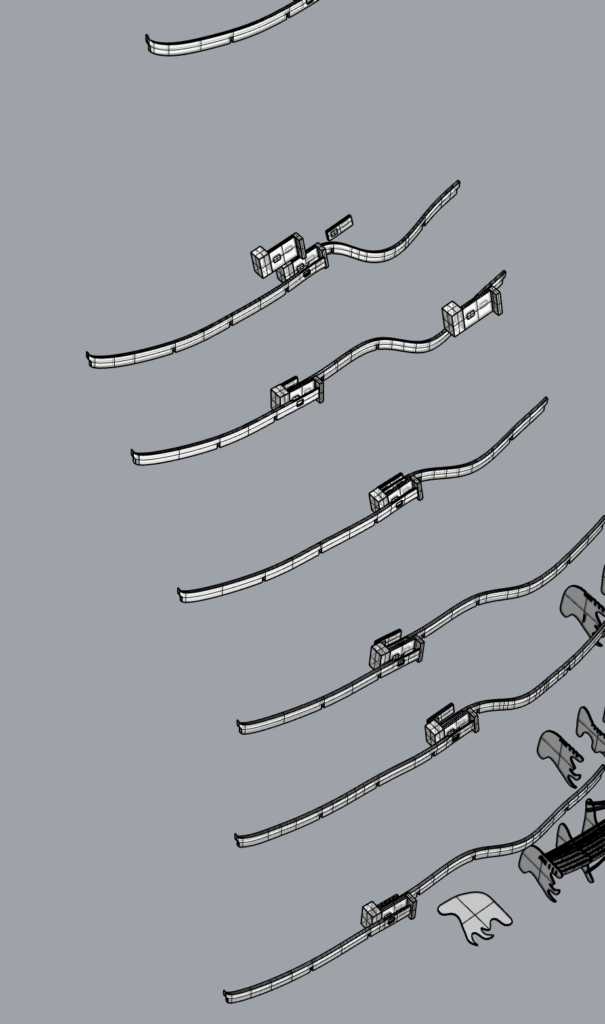

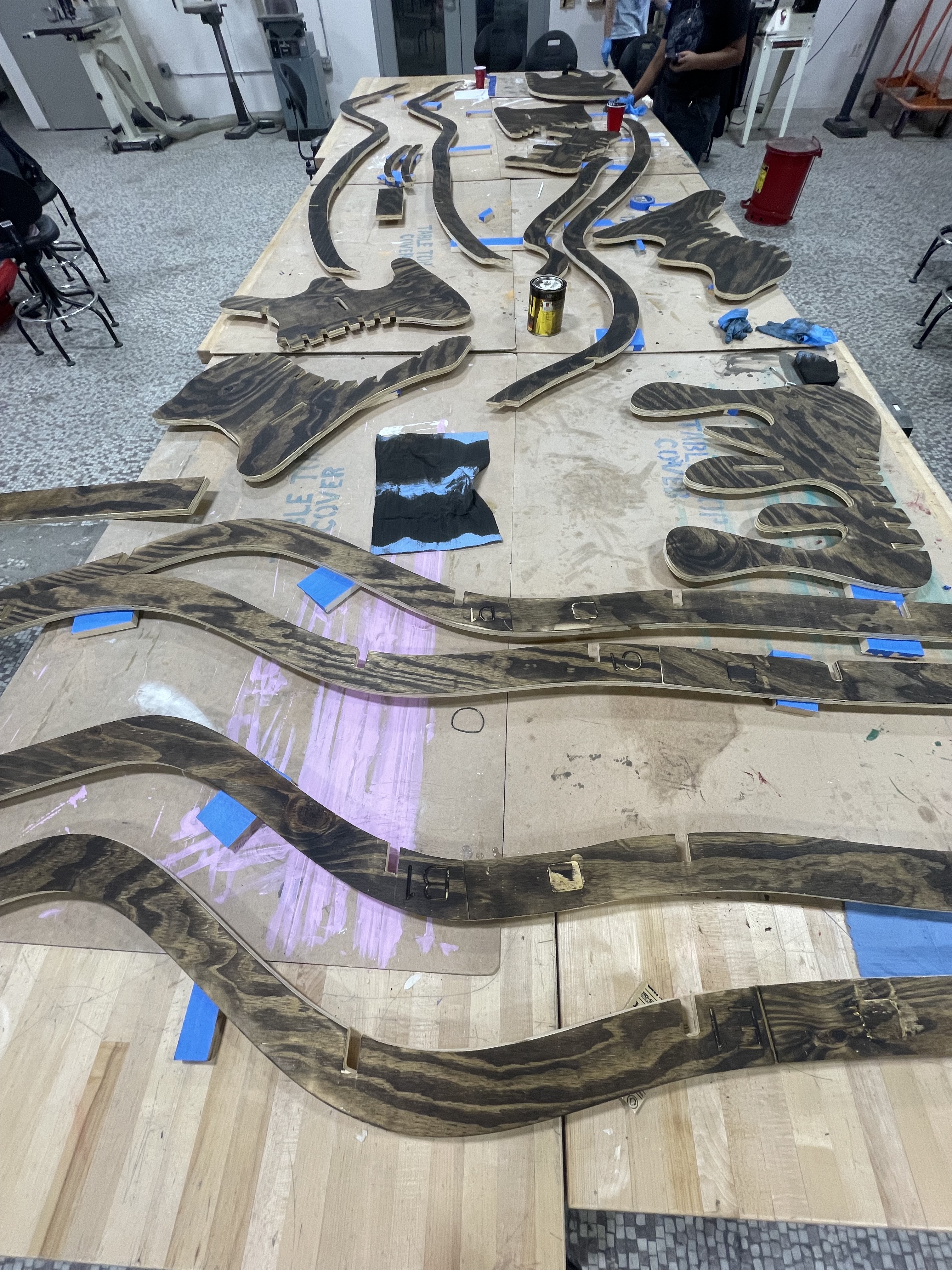

Skill Building

A series of technical exercises build and demonstrate skills in Rhino, laser cutting, 3D printing, and CNC routing.

Rhino

files:

Laser Cutting

files:

3D Printing

files:

CNC Routing

files:

Project I: Title

Replace the “Title” with the title of your piece or a simple description of the piece or assignment.

Replace all the text in this box with a brief overview of your piece (50-300 words)

Load your project overview images in the gallery below. The exact number of images is flexible, but 3-6 images is usually good for this.

Then do a little sidebar action:

In the right hand sidebar, click the “Document” tab to bring up setting for this post. Confirm that the “Categories” are set to “Portfolio” and “Portfolio 2020” only. Add a few keywords specific to your project in the “tags” section. Set/update the “Featured Image” for this post to the most appropriate for the banner on your portfolio page; this will be what represents your portfolio in the aggregate lists of portfolios on the site. Lastly, confirm the the layout is set to “Custom” and “One Column: Wide.”

Project II: Title

—

Project III:

—

Process

–

Research

.

Alex Bard

Ryan Hoover

Intro to Digital Fabrication

3D Scanning

Innovation and stewardship have been in constant flux in regards to technology.

Like any new tool or technology 3D scanning needs to be properly utilized. There are potential pitfalls with an excess reliance on scanning technology yet offers many opportunities and accessibility. Technology isn’t inherently bad only when it is left up to the users and their intent.

Similar to any technology that brings a radical shift in lifestyle akin to technologies from the industrial revolution. 3d scanning started picking up traction in the 1960s utilizing cameras and lighting to record objects. Francois Willeme invented the groundbreaking method of 3d scanning that has modern equivalencies today. Willeme called his process “photosculpting” and utilized 24 cameras at 15 degree intervals to capture the subject in the center of the cameras. (https://www.historyofinformation.com/detail.php?id=3876) with Willeme’s process he would trace the photographs onto slices of wood and gradual build the object from the photos previously collected from the subject.

Lasers started to innovate the scanning process. The next step was laser point recording and then stripe lasers which optimized work flow and details being scanned.

The 3d scanner is serving as an integral component in the digital industrialization currently occurring. Utilizing an intuitive technical approach 3d scanners have found applications in nearly every industry. Essentially the purpose is digitize any physical object and allow it to be altered or stored electronically through any other program or computer system.

Some of the various methods include Stereo vision and photogrammetry.

Stereo vision uses camera at two different angles. Photogrammetry uses more cameras at more angles. This method compiles several photos and analyzes the structure of an object based on the given photos. Similar in principle to Willemes precursor of photosculpture. Structured light scanning uses light to determine shape of the object. The distortions in the shape of projected light provide data for the camera. A projected beam measures out the distortions that are made from being projected onto an object and records that data. Time of flight uses timing of lasers between object and the laser source often highly sophisticated and expensive. Often times sends out a beam of light that bounces off an object which the sensor records the time between light being sent out and return as data points eventually building into an environment or building.

Depending on the data and object being scanned the purposes are vast and constantly evolving. Manufacturing, Art, architecture, urban planning, medical, prototyping, real estate, land management and entertainment are a few industries already utilizing 3d scanning technology. Average prices for 3d scanning devices these days range from hundreds to thousands of dollars depending on the application and detail required for the job. With different applications and entry points for products and services it is becoming another component in 3d printing ; digital lifestyles; and manufacturing.

Following the usual trend of technology 3d scanners were bulky and inefficient and have quickly slim down and become vastly effective compared to their predecessors. Instances of companies with warehouses full of a tool catalogue from past products can become digitized and free up that physical space. Take scan the world for example where they are offering a service to museums to scan and digitize their collections (https://www.myminifactory.com/scantheworld/about). Even mentioned in their manifesto Scan the world are realizing the pitfalls that can be possible with the technology they are using as digitizing everything for the world and the separation in human interaction that can come with digital saturation.

Along with this practice the increase of digitized objects leads to social media platforms that disseminate those objects for user participation. Leading to massive replication out of control of the original author. Speculating into the future legal challenges there could be criminal radical groups taking scans and selling those or destroying the originals.

Corporate espionage where spies go in and reverse engineer products; military espionage and art thievery could increase. Some of the positive optimism would be organizations enabling access to people that would otherwise be incapable, Museum scanning.

Applications are limitless as it can streamline the process of modelling digitally. allowing for quicker reproduction or modification of preexisting objects. Taking those digital files and then reproducing through a variety of 3d printing processes. Like any new technology it needs to be properly utilized and be met with responsible stewardship to ensure a more holistic balance. Ultimately, I’m optimistic and interested in this technology I’m just ambivalent of the possible misuse or inevitable conflicts that may arise from this innovation.

Ultimately, if humanity is always trying to recreate or capture the some essence of reality in art or scicence there are always various means and methods that will be utilized and 3d scanning is just another tool in the ongoing evolution of creativity and innovation. As with any other tool or technology there is no inherent evil or problem with the tech it is up to people to serve as stewards and work with the technology to contribute beneficially.

https://www.historyofinformation.com/detail.php?id=3876

https://matterandform.net/blog/how-3d-scans-can-bring-the-museum-to-you

https://circuitdigest.com/article/3d-scanning-technology-advantages-challenges-and-future

https://www.myminifactory.com/scantheworld/about

https://www.actasimulatio.eu/issues/2018/IV_2018_01_Edl_Mizerak_Trojan.pdf

More Information

additional information and links