Avinoam Drabkin, Product Design (major) Ceramics (minor), Class of 2026

Avinoam Drabkin (Avi is just fine) is a Baltimore based artist, and is excited to be in this class! His interests include nature, physical activity, music, and of course all sorts of ways of fabricating. He originally started his artistic journey through drawing and illustration, but eventually found his way to ceramics and other 3D making, while also acquiring an associate’s degree in classical piano performance along the way. He was able to transfer from community college with 2 years of his degree fulfilled, and now is looking forward to finishing his Bachelor’s at this institution!

Skill Building

A series of technical exercises build and demonstrate skills in Rhino, laser cutting, 3D printing, and CNC routing.

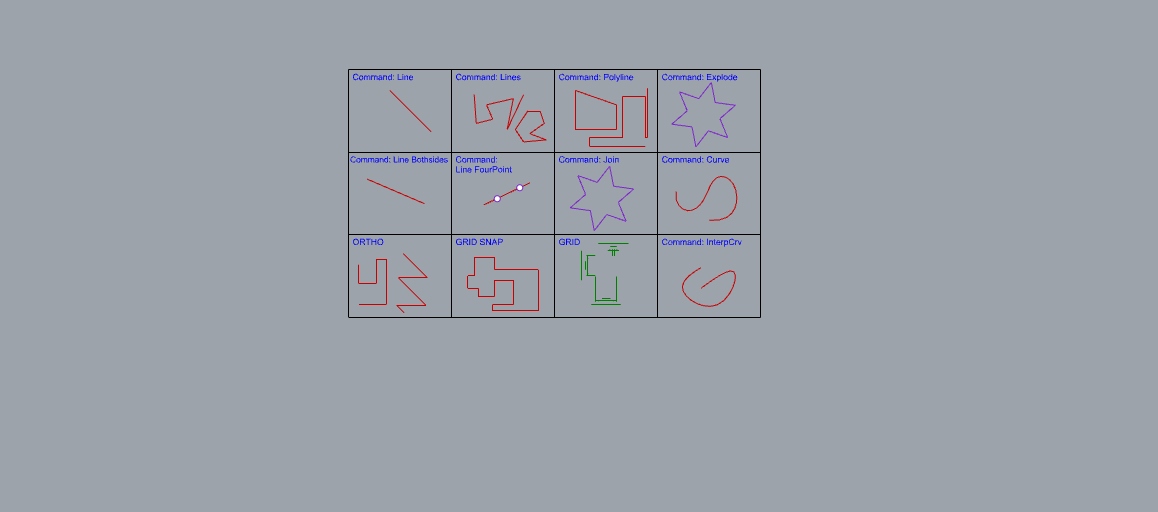

Rhino

files:

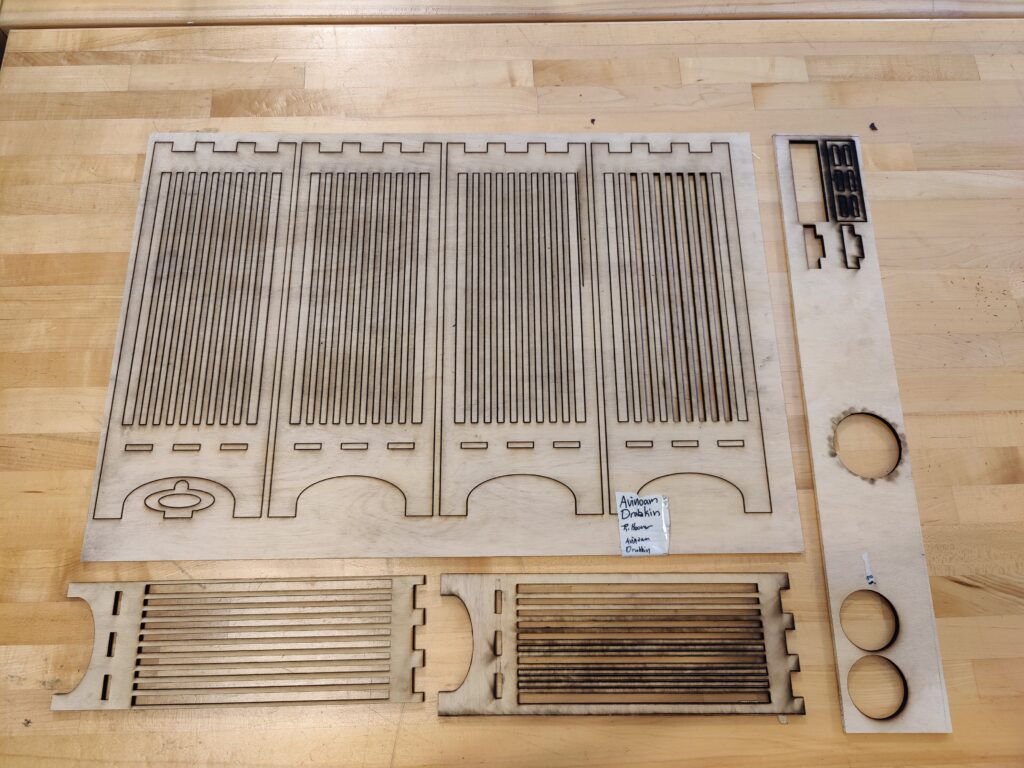

Project I: Light BOX

This piece was fun to make! I knew from my last class that I would have to do some experimenting to get my slots to fit correctly, and it turns out that the kerf of the laser pretty much made the slots fit well without the need of precise allowances. The orange light filters that I attached on the interior of the walls also did a wonderful job of changing the colored light from the bulb within, and I enjoyed the lighting affects that were achieved.

Process

I first began by making the file for cutting. I then did testing for slots and the correct fit after acquiring my material. I then cut out the pieces and assembled them while also attaching the interior light filters for coloring. After that all it needed was a light source inside. Unfortunately a had a few failures with the laser cutter due to some unclean lenses but eventually was able to get a successful cut.

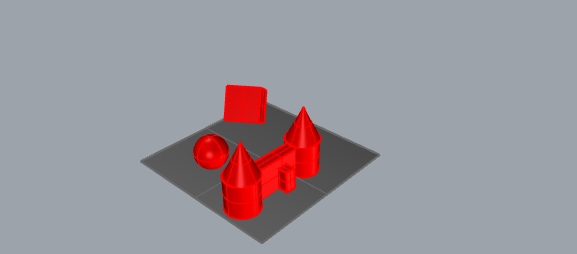

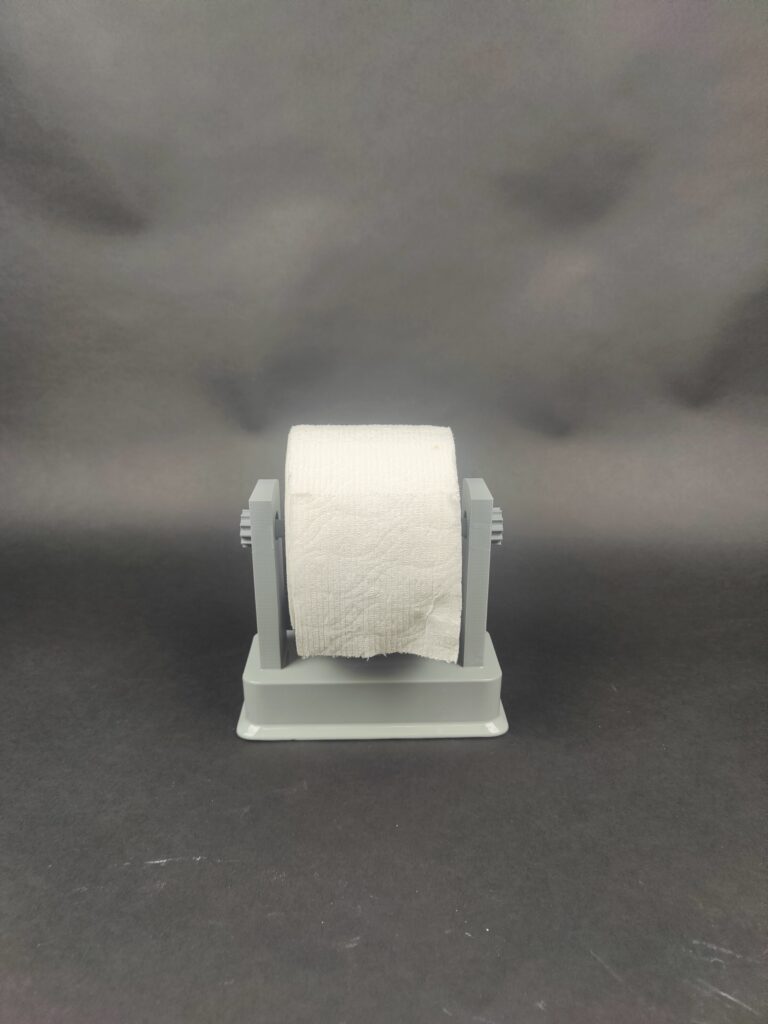

Project II: Toilet Paper Holder

I started this project with the phone charging block that I modeled in a previous exercise. I was turning it around in my hands when I suddenly realized that the holes in the prongs were a perfect opportunity to slide something through, and what better than a bar or connection of some sort to hold toilet paper! I had already made some sketches this sort of product earlier in the semester so I wanted to take advantage of the project to bring something to fruition. The two bits on either side can be gripped and turned in the fingers for rolling, but it can be traditionally pulled as well. The two bits screw into a middle bar that fits to the toilet paper roll.

Process

When approaching this project, I mainly needed to modify the plug so it could sit low enough to the surface, but also be stable enough to sit without much movement when pulling on the roll. The modeling was not overly difficult, but I had issues with some chamfers and filleting that took time to figure out. It took a few tries to get a successful print out as well; the first few had some odd failures that we couldn’t exactly figure out.

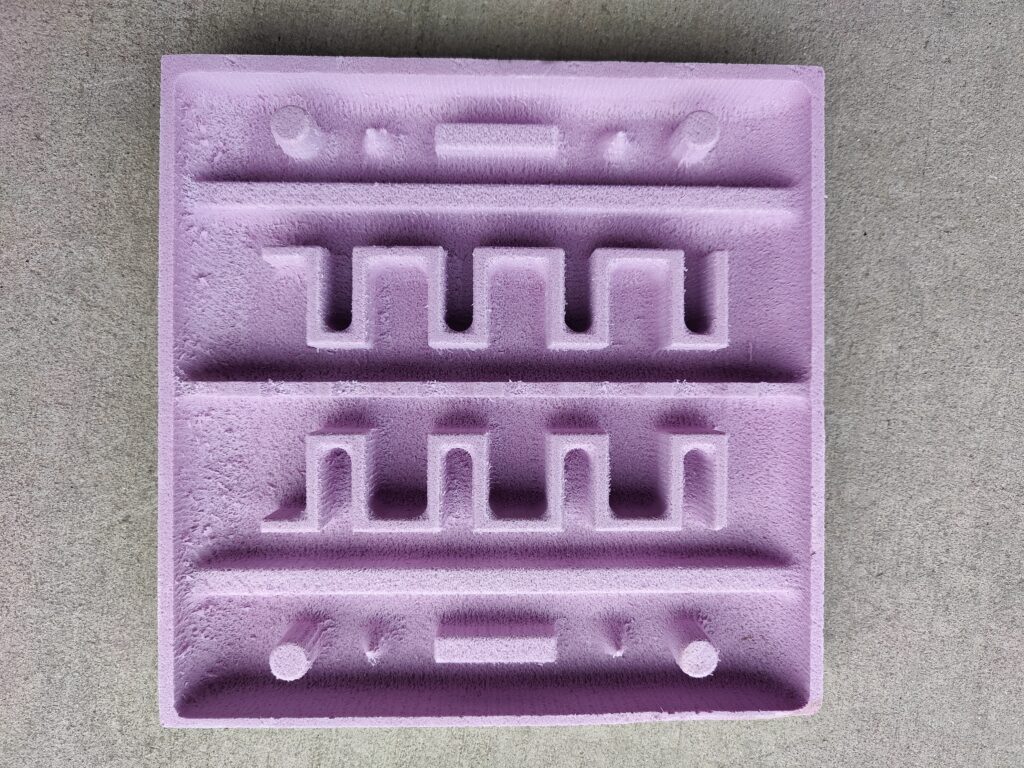

Privacy Screen

For this project the class decided on a privacy screen of sorts. We would each make one panel with a design of our choosing, and on the last day we assembled everything. For my panel I knew I wanted a repeated pattern design that went all the way through the material, and I ended up settling on a sun motif pattern, which CNC’ed relatively well. A dull bit broke in the middle of the cut but we recovered nicely.

Process

The process for this was relatively simple. I just had to make the model in rhino, and camming the toolpaths wasn’t the hardest job since everything was being 2D milled and I purposefully made the lines so that they could accommodate the drill bits without issue. Once all the panels and frames were cut for the pieces, it was just a matter of assembling. The hardest part was figuring out the hinges.

Research

https://docs.google.com/presentation/d/1ePy069lIGZtb3aMXzqzc_x63X3-gHAKDltfz4Bmn-No/edit?usp=sharing

https://docs.google.com/document/d/1Ih6dJM2bqYMvhYX7tzEx8XaHsZ6SdhOHNXNaxXE3tQc/edit?usp=sharing

More Information

additional information and links