THE DANGER OF PLANNED OBSOLESCENCE

Planned obsolescence is a phenomenon observed across technological industries, referring to the practice of designing and manufacturing goods that prematurely break or fail, and require frequent replacing. It is especially widespread with medical technology. In the assistive care industry, 3D printing has become an effective solution for manufacturing medical devices that are long lasting by introducing rapid prototyping, customization and cost-effective production tailored to patients’ needs. Overall, the potential of 3D printing reduces the financial strain on hospitals and patients, extending the lifespan of components.

CONTENT ANALYSIS BASED ON ONLINE REVIEWS

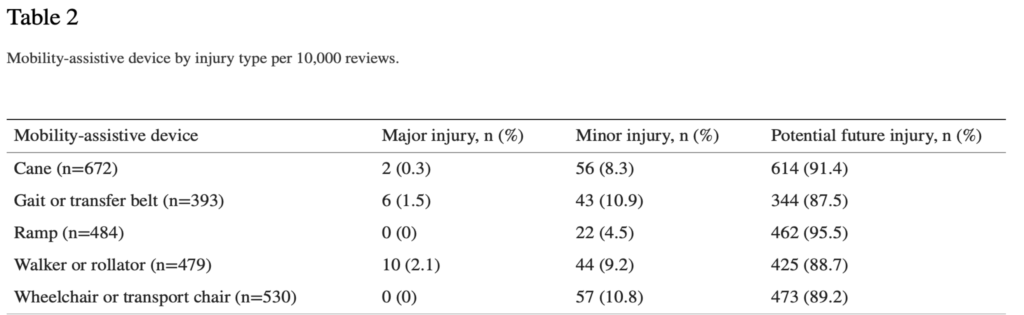

The lack of intentional design has led to many safety concerns among the elderly and disabled. These products are not made to last, and the poor quality of the materials make them difficult to repair. Researchers at the Virginia Tech Data & Decision Sciences department conducted a large-scale study investigating injuries stemming from the use of mobility devices. Data was compiled from product reviews in Amazon’s assistive care categories, and filtered based on product and injury type. The study concluded that “overall, per 10,000 reviews, 240 (2.4%) [customers] described mobility-assistive equipment–related user injuries, whereas 2318 (23.18%) revealed potential future injuries.[7]”

Defective Items and sudden breakages account for nearly half of the injuries labeled in the dataset ranging from 14 to 29%, overshadowing any reports of misuse from the user. Device manufacturer’s reliance on planned obsolescence is a key figure in the financial challenges many hospitals face today. Many devices are designed with single use locks which prevent hospitals from reprocessing items to be reused as opposed to repurchasing them at increasingly expensive cost. Reprocessing programs provide the healthcare provider the benefit of reusing the device and significantly reducing cost. Lars Thording Ph.d. of Innovative Health, a reprocessing company, reported that “Cost per catheter use, in some cases, can go down by $1,000 or more, which matters a lot in an A-Fib procedure, where device costs are more than $10,000[7]”. However some manufacturers have gone as far as to remove their tech from labs and operating rooms when a hospital participates in the program.

MAKER HEALTH

To combat this, healthcare company Maker Health has provided hospitals with digital fabrication labs, referred to as MakerSpaces, for practitioners to design and create equipment for patients. Providers have used these spaces to 3D print equipment ranging from cleft plate models and pacemakers to more unique and personalized items for patients such as customized handles. Items are reviewed by an innovation safety council that test for risk, chances for contamination, and fail proofs to keep patients safe. Rose Hedges, Nurse at Unity Point Hospital has stated that, “We do a lot of 3D printing. We have several 3D printers that they’re constantly running, whether we’re fixing a face plate for an IV holder, one that broke. [3]”. This has significantly reduced cost as the entire unit does not have to be replaced. MakerSpaces have become capable of providing patients and caregivers with autonomy and self-reliance to facilitate more personalized care.

3D PRINTING FOOD

Khoo Teck Puat Hospital in Singapore has used 3D printing technology to create meals for its elderly patients that have difficulty chewing and swallowing food. These types of printers use an edible filament to create food that is familiar to the patient to stimulate their appetites. Meals include chili crab, durian and bitter melon which resemble the taste and design of the real thing, and can be customized to fit a patient’s dietary needs [6].

Tatsuo Ishibashi & Mizu Lab

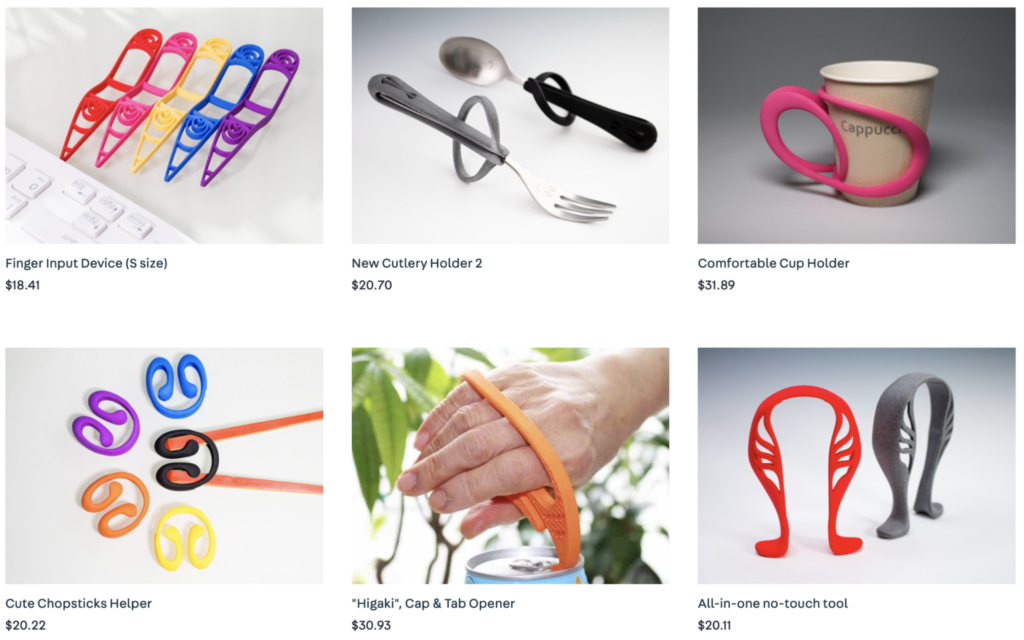

3D fabrication of assistive devices also extends to the individual level. Tatsuo Ishibashi, founder and owner of Mizu-Lab, looks to make these types of devices inclusive and accessible to the differently abled. Ishibashi channels his expertise as an engineer to design objects including a cutlery holder, finger input device and an all-in-one no-touch tool that keeps hands away from contaminated surfaces [4]. His designs also focus on aesthetics to create objects that are also visually appealing. These apparatus along with his other designs are readily available on his website for purchase.

To conclude, 3D printing holds unlimited potential in revolutionizing the medical industry and assistive device manufacturing. Material engineers, university researchers and companies like Maker Health and Mizu Lab display the possibilities of these technologies. Digital fabrication for assistive care will increasingly benefit a wide range of professionals, from caretakers to engineers and medical practitioners, as innovation and accessibility continue to expand.

Citations:

[1] Dodziuk, H. (2019, November 17). Application of 3D printing in healthcare of the elderly. https://www.akademiamedycyny.pl/wp-content/uploads/2020/03/Gerontologia_4_2019_07.pdf

[2] Gaskell, A. (2017, December 12). How 3D printing can support elderly care. AdiGaskell.org. https://adigaskell.org/2017/12/12/how-3d-printing-can-support-elderly-care/

[3] Dougherty, Dale. “What Nurses Make in a Hospital Makerspace.” Make: DIY Projects and Ideas for Makers, 12 May 2023, makezine.com/article/workshop/makerspace/what-nurses-make-in-a-hospital-makerspace/. Accessed 1 Apr. 2024.

[4] “Developing 3D Printed Assistive Tools for the Elderly – Shapeways Blog.” Www.shapeways.com, www.shapeways.com/blog/developing-3d-printed-products-for-the-elderly.

[5] Ma, Meng et al. “Applications of 3D printing in aging.” International journal of bioprinting vol. 9,4 732. 11 Apr. 2023, doi:10.18063/ijb.732

[6] Ng, Desmond, and Millet Enriquez. “How 3D Food Printing Can Help the Elderly.” CNA, 22 Dec. 2020, www.channelnewsasia.com/cna-insider/how-3d-food-printing-can-help-elderly-780761. Accessed 1 Apr. 2024.[7] Thording, L. (2018, October 16). Column – planned obsolescence and single-use reprocessing in Healthcare. MedTech Intelligence. https://medtechintelligence.com/column/planned-obsolescence-and-single-use-reprocessing-in-healthcare/#:~:text=Planned%20Obsolescence%20as%20a%20Barrier%20to%20Device%20Reprocessing&text=However%2C%20it%20is%20especially%20prevalent,that%20they%20cannot%20be%20reprocessed.