Kimari Hazward, IS, 2025

Kimari Hazward is an Interdisciplinary artist from Brooklyn, NY. Kimari’s work explores the ways in which architecture, objects and family history act as metaphysical spaces that can produce both liberating and carceral possibilities for black individuals.

Skill Building

A series of technical exercises build and demonstrate skills in Rhino, laser cutting, 3D printing, and CNC routing.

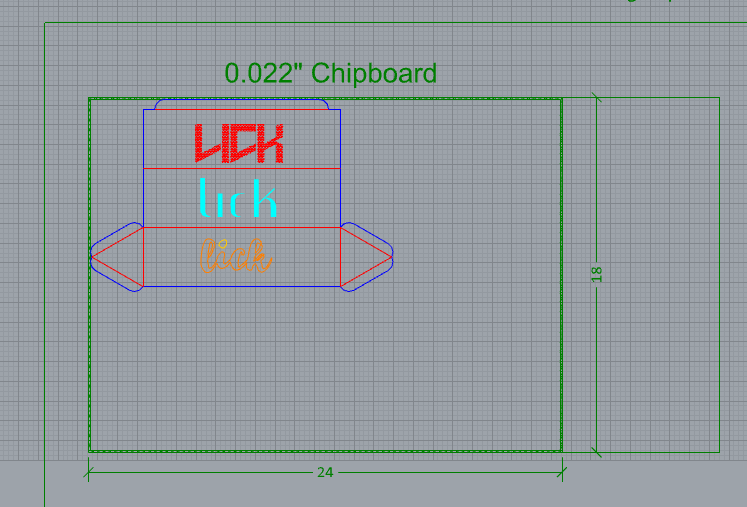

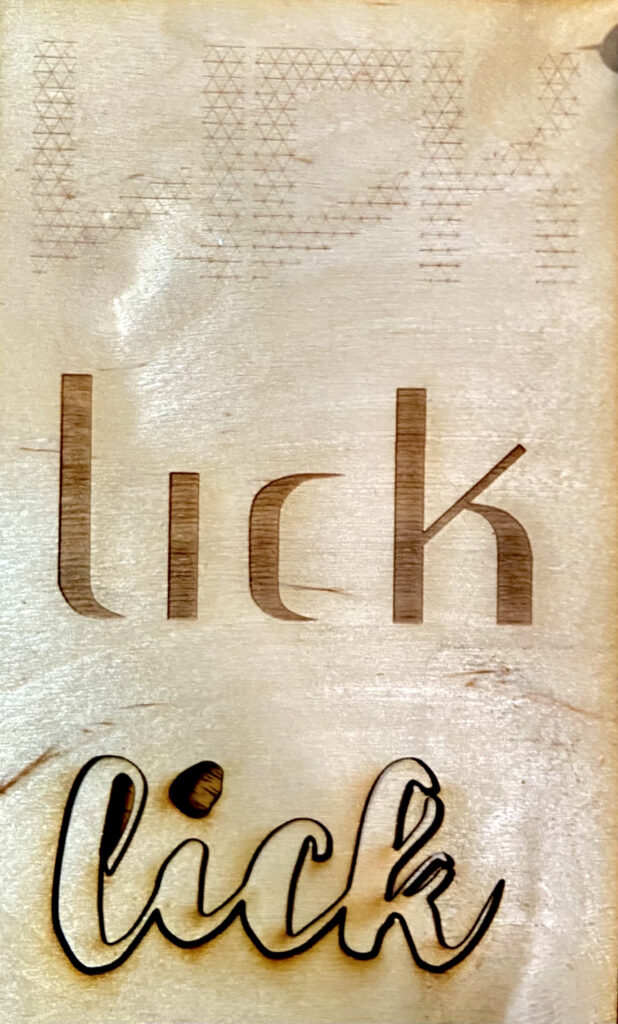

Rhino

files: Word Tracing Demo In Rhino

Laser Cutting

files:

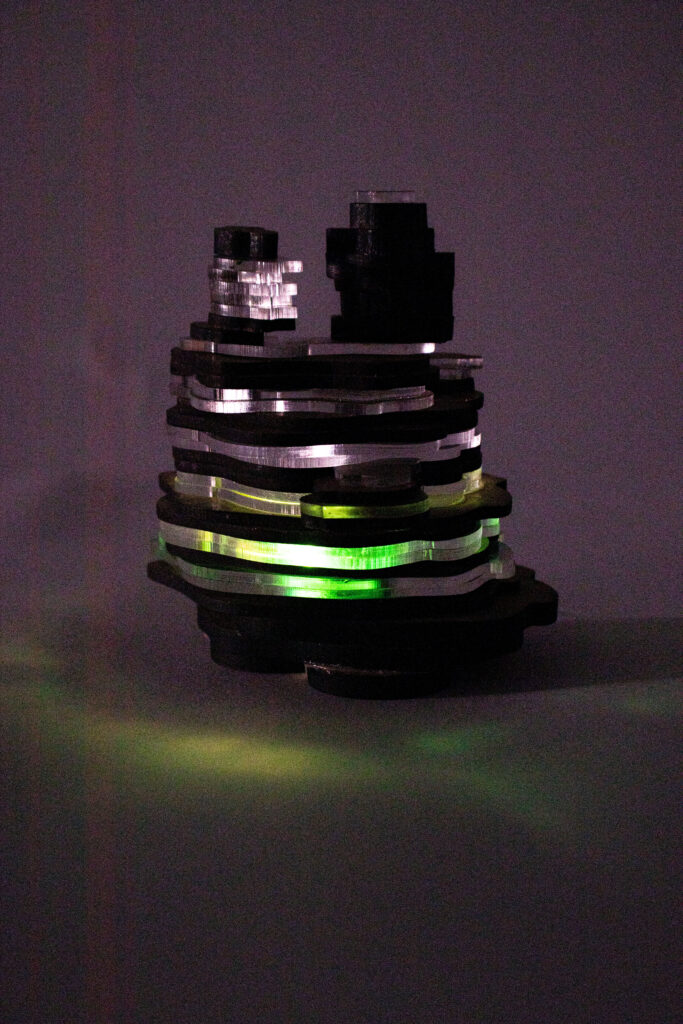

Project I: Terrain Lamp

‘Terrain Lamp’ is an interactive lighting structure that can be shifted and arranged to fit the user’s ideal shape.

Process

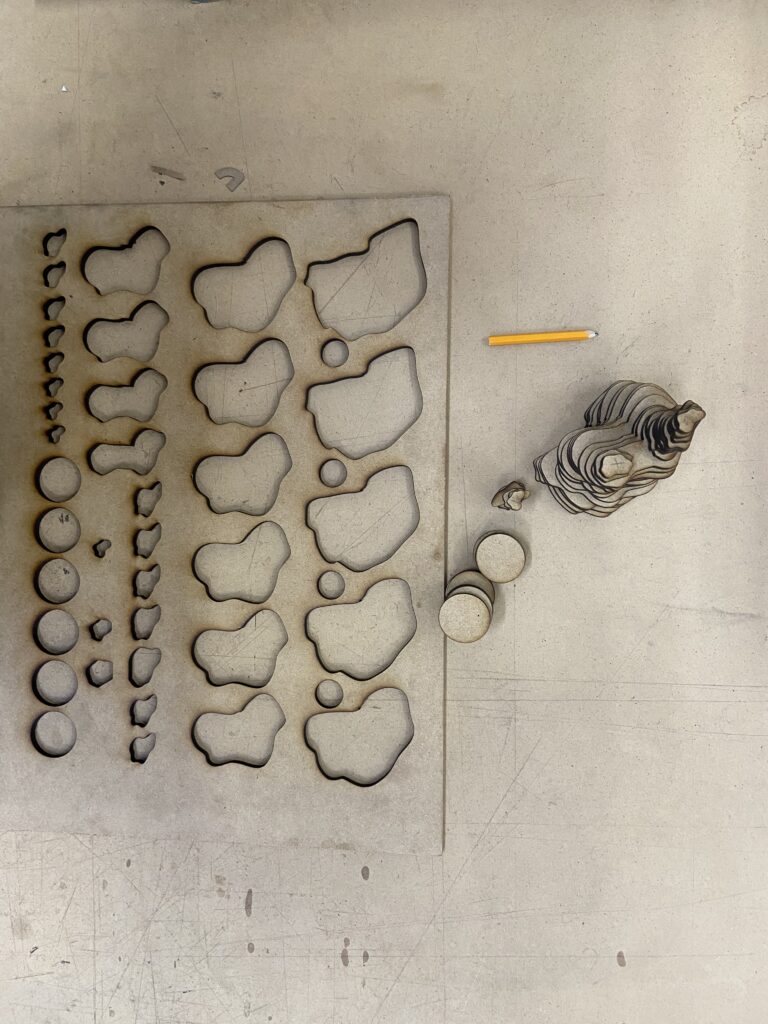

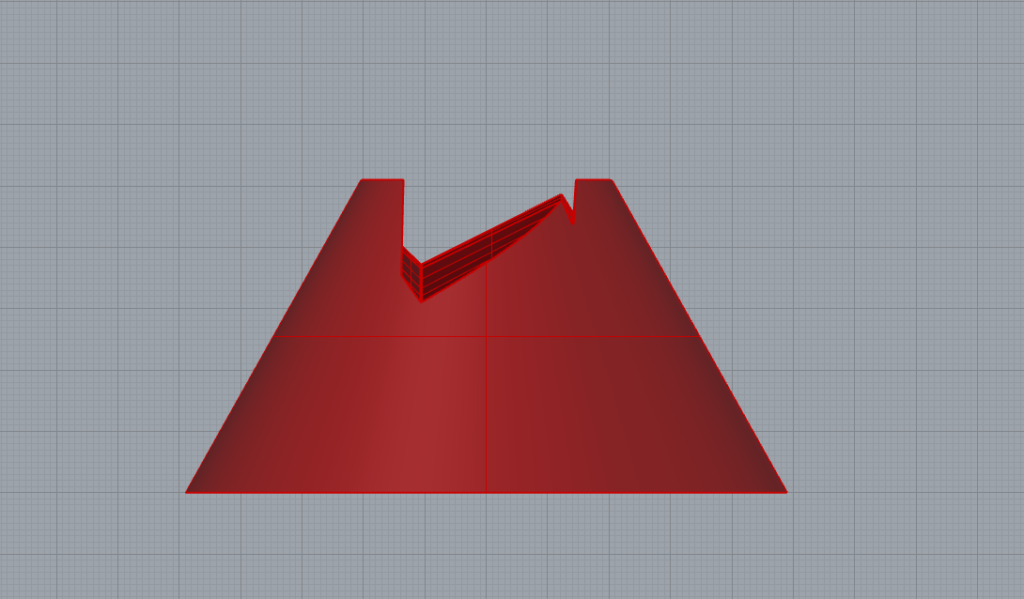

I began working on this piece by forming layers of similar shapes, starting from the bottom layer and moving inward with slight variations via size and form. Once I finalized my shape I tested the form out by making a 3D figure based on the layers and placed a hole on each shape to fit a dowel. After aligning these layers based on the laser cutting template, I used both fiber board to achieve the desired look of a mountainous terrain and plexiglass for the light to shine through. After layering each piece using both a dowel and glue, I placed the light within the concealed holes of the bottom layers and wrapped it around green gel sheet to create the colored lighting effect.

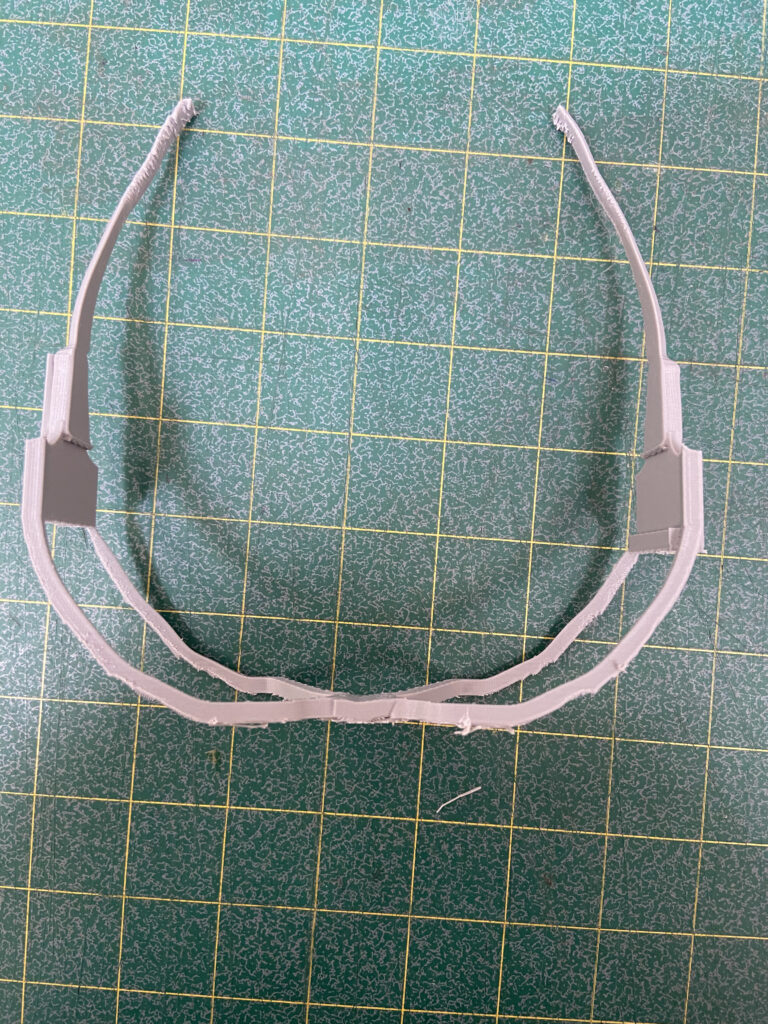

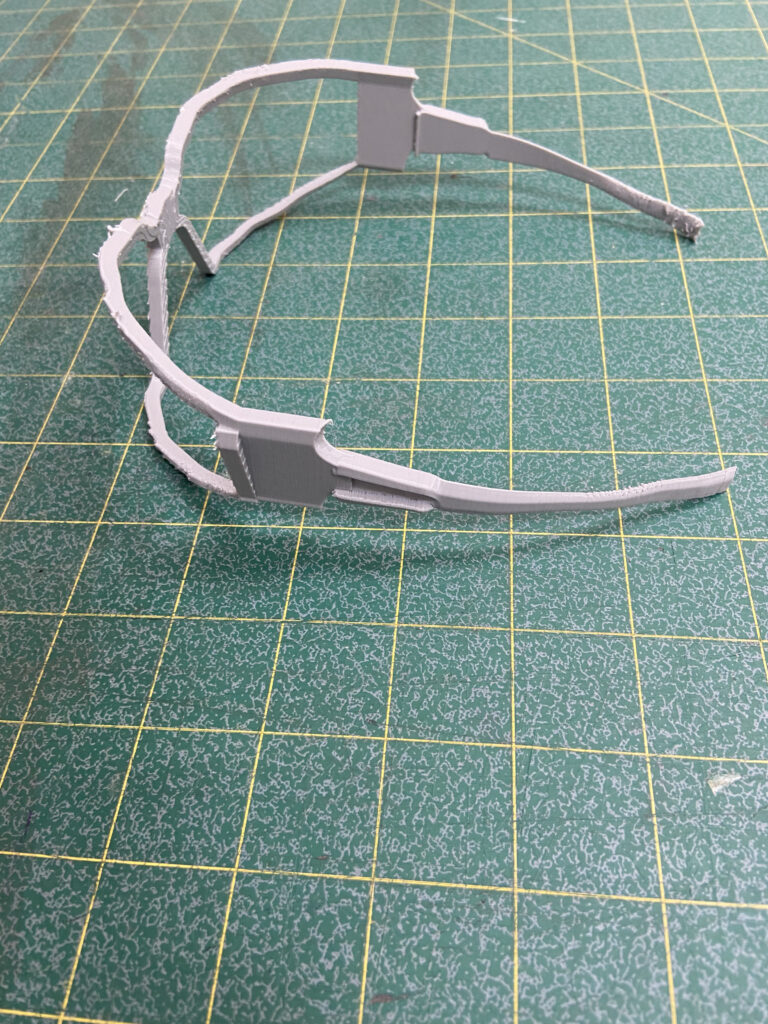

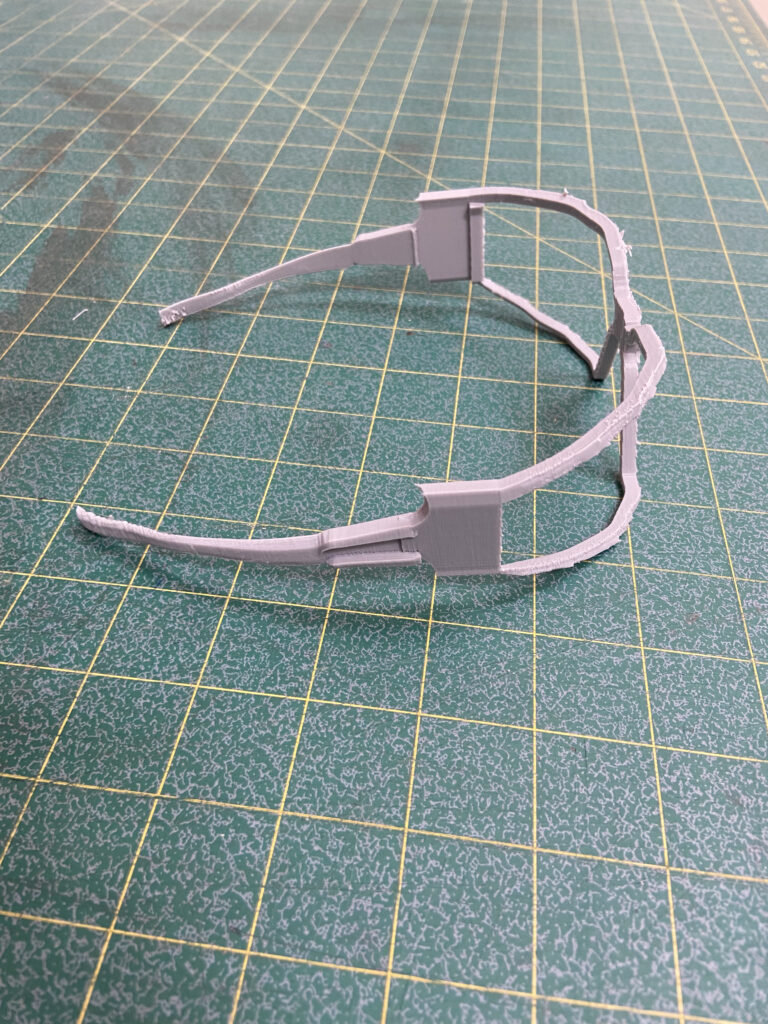

Project II: Alien Claw

This project depicts an alien form holding crystal like structure composed of fiber glass and chicken wire coated in fiber glass resin.

Process

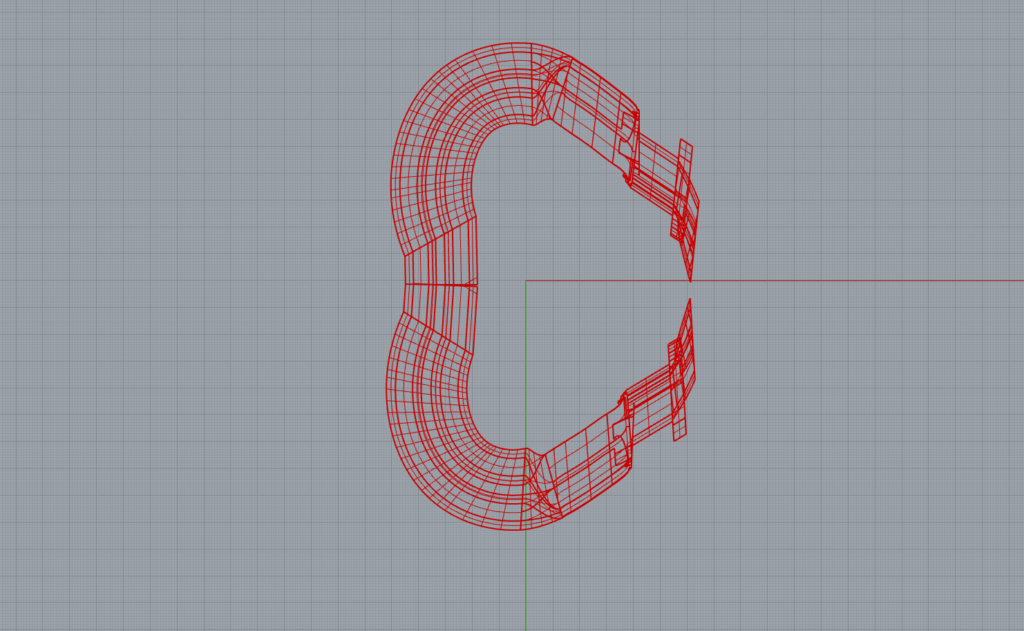

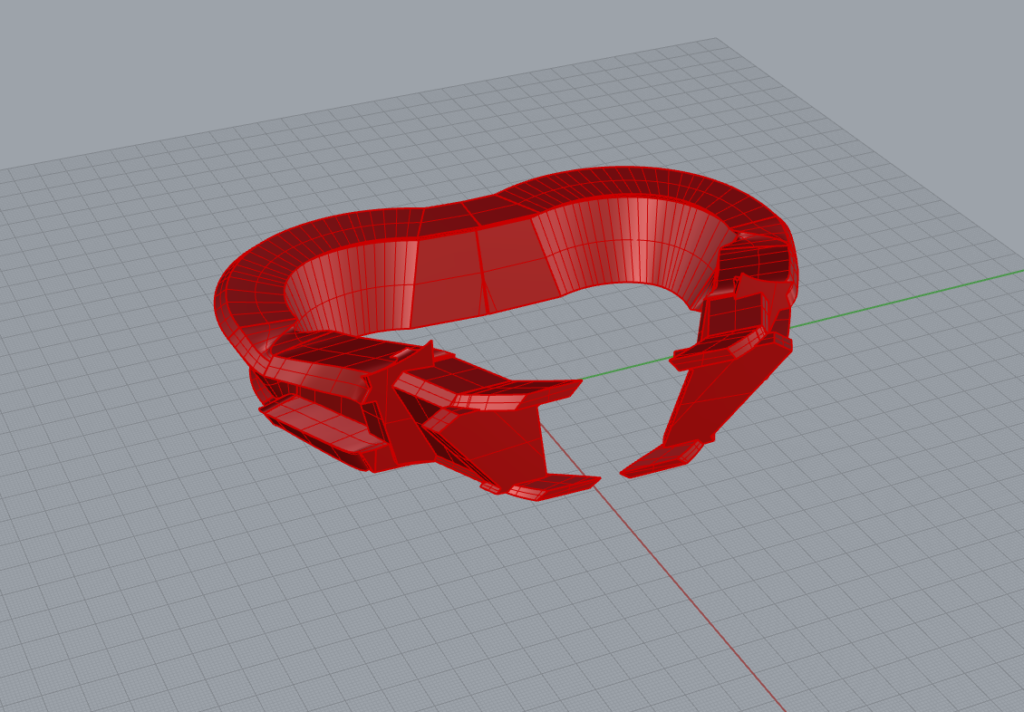

For this iteration of the 3D printing project, I altered my render of my sunglasses into an alien like claw object. I removed most of the components of the sunglasses, only using the temple and frame rims as the primary parts to create this piece. I then created the stand by using the Boolean difference command on the rounded prism shape.

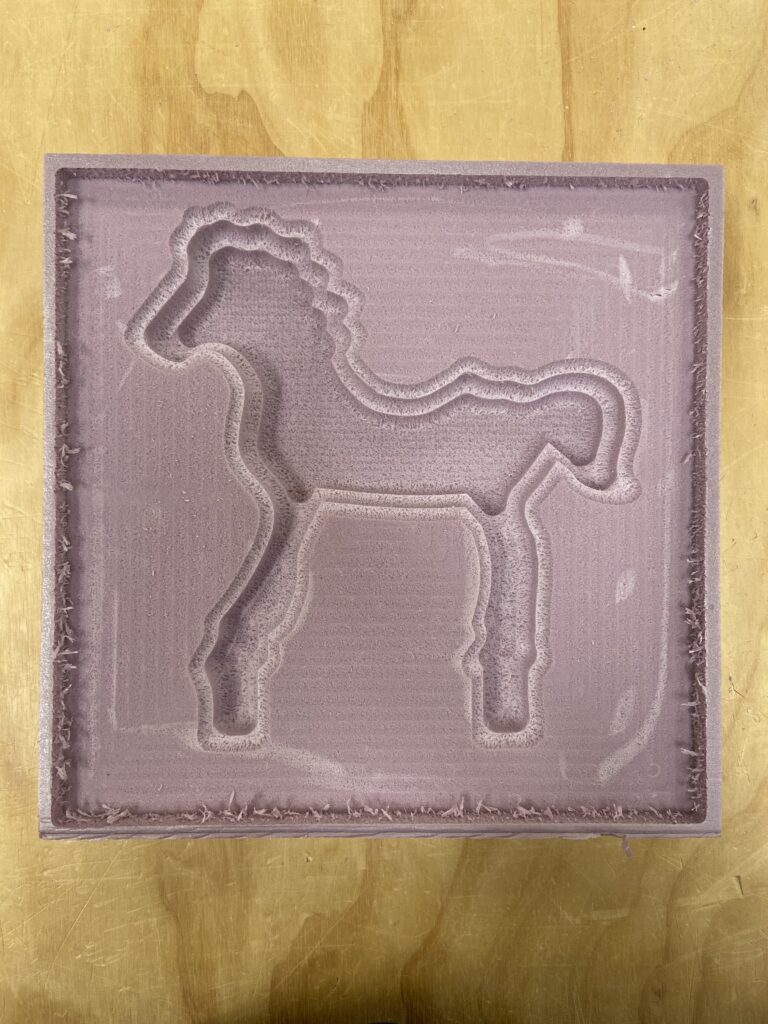

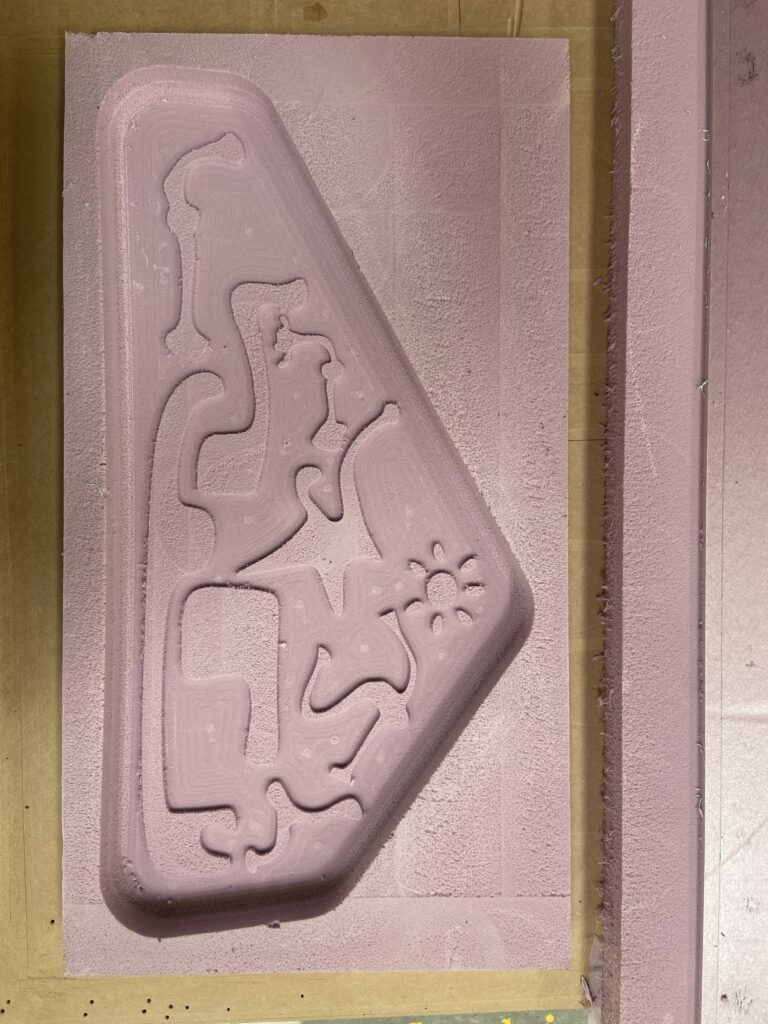

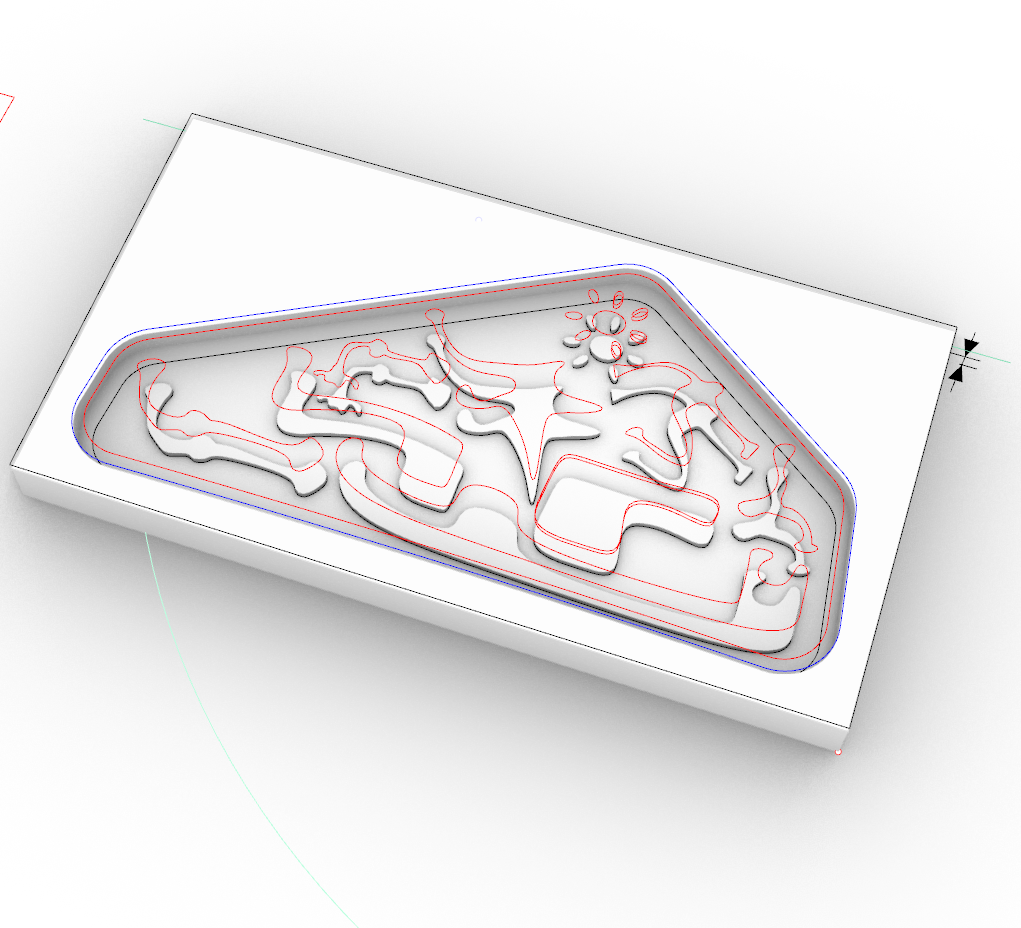

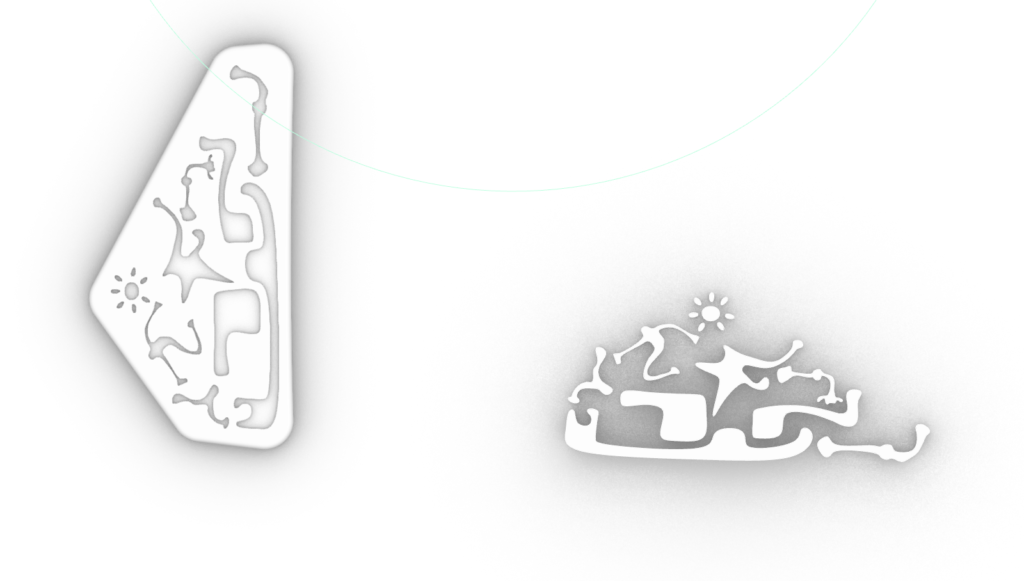

Project III: Garden Tile

For this project, I drafted a series of amoeba-like shapes resembling both figures and landscapes to depict a playful scene under the scene.

Process

I started by creating the initial form in Rhino Cam to then CNC the details in foam. Afterward, we mixed and poured concrete into the mold making sure to keep in moist until demolding. When the concrete dried, we set it up outside to be placed in the garden.

Research

Presentation: How 3D Printing can change the future for Assistive Devices

More Information

additional information and links