Possibilities of 3D Print in Clothing and Accessories

Iris Van Herpen

A Dutch fashion designer who always uses 3D print, laser cut, and other digital fabrication technologies in clothes.

YVMIN

A Chinese accessories brand which combines 3D printing technologies in their products.

3D printing is already really mature in fashion area, and it’s also a perfect way for all these brands want to achieve the futuristic feeling in their products. They print extremely detailed, and change the appearance after printing using electroplating to achieve the shiny metal outer layer of the products.

Possibilities of 3D Print Materials

For the previous products in fashion area, they are changed the appearance after printing. However, the materials used for filaments in 3D print also have a huge range of diversities, so by changing the materials, people can get different appearances before printing.

3D Print in Ceramics and Soil

3D print in ceramics is a really common technology for nowadays, and people can use it for ceramic sculpture and architectural models.

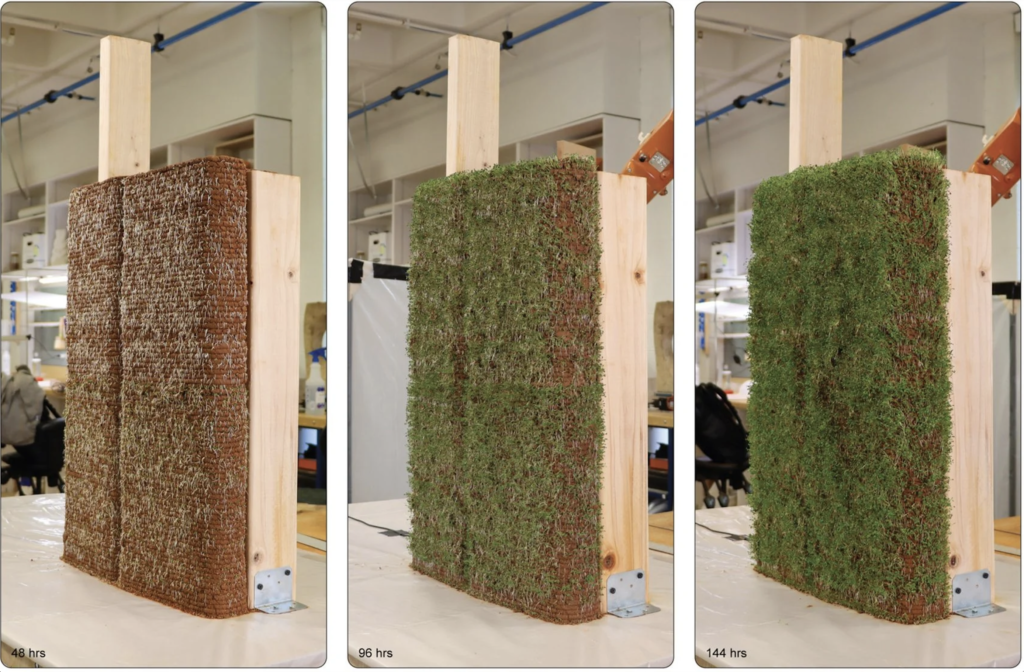

University of Virginia has a research team invented a 3D print machine in soil implemented with seeds, and this machine is based the structure of cement and ceramics 3D print machine.

Their idea is that the plants are no longer layered on the top, but inside the structure of architecture. With this kind of structure, it can reduce the carbon dioxide in the atmosphere, and create sustainable way for materials.

3D Print in Glass

Neri Oxman and her research team created a 3D print machine can use glass as the filaments.

They did a lot of experiments with how the machine can print different forms of glass, and when the lights pass through the different forms, how the shadows will change.

For further development, they explore how the lights affect shadows in a dynamic way.

3D Print in Synthesized Materials

Clay, soil and glass are relatively considered as ready-made materials. The filaments of 3D printing can be more diverse with biological elements.

Tree Column by Blast Studio

The materials they used in this project are mycelium and coffee cups, and it has the function of growing fungi and decomposing coffee cups. They created an algorithm that generates shapes conductive to the growth of the mycelium. The shapes generated reproduce the ideal climate for the growth of fungi by retaining moisture in their interstices and protecting the mycelium from air flow. Thus, the mycelium can develop to its maximum capacity in these warm and humid spaces.

Otrivin Air Lab by ecoLogicStudio

Harvest algae

Bioplastic

3D Printing Filaments

In the lab, they harvest carbon dioxide, purify polluted city air and 3D print plastic-free biodegradable products. At the Otrivin Air Lab, ecoLogicStudio’s biological designers will create a catalog of material samples with a variety of properties that come directly from daily harvests. From bioplastics and bio-rubber to 3D printed algae filaments, they will test various strains of algae, resulting in a beautiful catalog of color gradients. These hand-crafted filaments will be used in a real-time 3D printing process to produce carbon-neutral products.

Citation

- https://www.instagram.com/irisvanherpen/

- https://www.instagram.com/yvmin_official/

- https://www.saic.edu/academics/departments/ceramics/resources

- https://www.dezeen.com/2022/09/05/university-of-virginia-3d-printed-soil-seed-walls/

- https://oxman.com/projects/glass-i

- https://www.youtube.com/c/oxmanofficial

- https://www.blast-studio.com/tree-column

- https://www.ecologicstudio.com/projects/otrivin-air-lab