Do you like sushi? While sushi is generally considered to be a healthier alternative to other foods, this futuristic restaurant in Tokyo, Japan is taking things to another level. Sushi Singularity, a Tokyo restaurant by Open Meals (a Japanese company dedicated to facilitating a new food revolution) is offering personalized sushi based on each guest’s health and nutrient needs. They aim to revolutionize sushi by digitizing its ingredients, designs, and flavors.

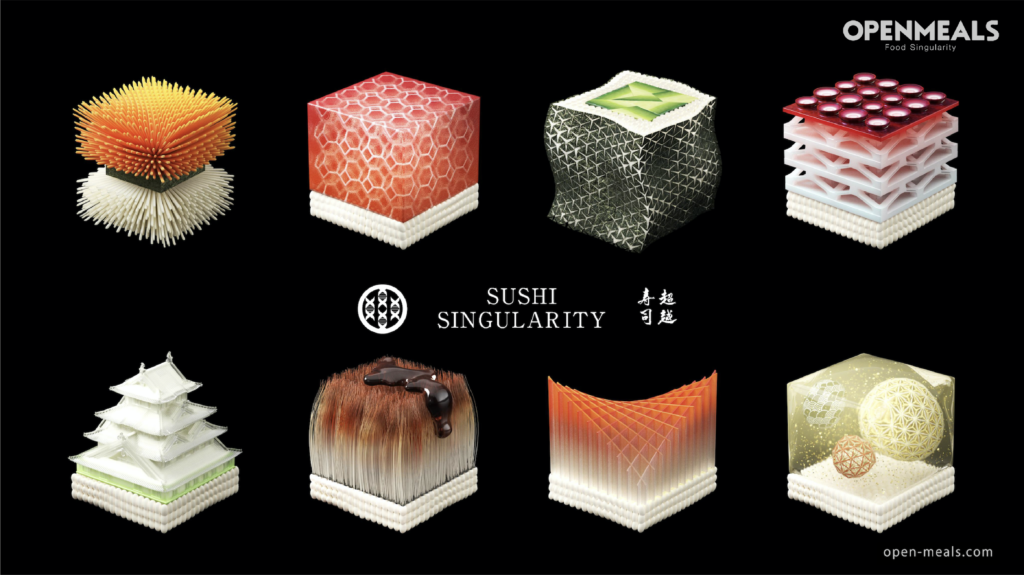

This dining process starts with a health test kit, which is used to collect saliva, urine, and intestine tests from the customer. Once the data is collected, the restaurant will analyze these data and design a nutrient-optimized meal that is customized for this person. This design process is realized through a food operation system and is stored in .cube format, which decomposes the ingredients that make up the dish and reconstructs them in a cube form of a three-centimeter square. There are nine basic elements, including nutrition, flavor, texture, fragrance, temperature, ingredient, ratio, order, and stacking method. And there are three ways to construct sushi: 1) layering, which expresses food by overlapping layers with different textures and flavors; 2) building a wall for soft ingredients to be created within; 3) confining the liquid by covering the whole surface with a thin film. The design can be shared through SFNS (Social Food Network Service). However, this platform is still under development.

After designing, it comes to actually making sushi. Open Meals designed this food fabrication machine that incorporates a variety of technologies. It consists of 13 sections:

- Food Ingredient Cartridges: These will contain sustainable food ingredients such as seaweed and crickets, which are mixed with water, fiber, and enzymes for output.

- Nutrient Cylinders: 14 types of nutrition ingredients in cylindrical cartridges. Foods will be nutritionally optimized based on a Health ID.

- Alginate Fermenter: Produces spherical food through a chemical reaction between sodium alginate and liquid calcium.

- Artificial light farm: Cultivates fresh vegetables in enclosed spaces through use of artificial light such as LEDs.

- Hot water FDM: Items that cannot be formed at room temperature or in air can be realized by outputting them in hot water.

- SLS: Laser-Sintered 3D Printer. Powder-based raw materials are baked into specific shapes using lasers.

- FFM Control Interface: The brain of the entire machine, which combines various data to design and hyper-personalize food.

- Laser FDM: Thermolysis Laminated 3D Printer, The raw material is melted by heat and formed by stacking layers.

- Robot arm: The unit is equipped with an ultra-high precision arm.

- Chilled FDM: Outputs at ultra-low temperatures to realize shapes impossible at room temperature.

- 6-axis NC router: Cuts the material with a multi-axis router, enabling precise, elaborate modeling.

- Fermenter: Cultivates food ingredients in real time through precise management of water temperature and nutrients.

- Light Scattering Analysis: The light scattering technique can be used to analyze the shaped object at the nano-level in a non-destructive and non-contact manner during output, to ensure consistent quality

I would like to emphasize two technologies here, which are SLS (selective laser sintering) and thermolysis laminated 3D printing. In SLS, the metal powder is heated just below its melting temperature through heating coils or infrared lamps and is kept at this temperature throughout the print so the laser can melt the powder easier. Then the print starts, a powder spreader such as a blade or roller creates a thin layer on the build platform and the laser selectively heats up regions of the build area to melt the powder in a defined geometry. This process is repeated. When it is done, the printed object will be surrounded with unmelted powder, which means it does not need any support material. So it’s easy to print weird or complicated designs.

Thermolysis laminated 3D printing can be done in the open air and at room temperature so people can embed things like wires into the print. It works in a way that basically welds numerous layers of the material together to form the shape. The welding head rolls over the sheets and vibrates so that each sheet gets welded to the other. Another advantage of this technology is that you can join dissimilar materials such as copper with aluminum, for the reason that they have different melting points.

Open Meal not only has this one project been developed. They did a project in 2018 called Sushi Teleportation, in which they break down sushi into pixels and print it out via a pixel food printer. Another project is called Cyber Wagashi, in which they 3D print Wagashi based on weather data, including the particular day, wind speed, atmospheric pressure, and temperature. We cannot deny that this company is very innovative and bold, but in terms of actual implementation, it is not promising for the fact that 3D printing technology has not yet reached a super level that is accurate and efficient enough to print food, not to mention food that you can actually eat. However, I still believe that at some point in the very far future, There will be a qualitative change in the way humans eat.

List of sources:

- N.d., “Restaurant Sushi Singularity”, Team Open Meals Japan Patent Pending, https://www.open-meals.com/sushisingularity/index_e.html

- Dr. D-Flo, “What is Selective Laser Sintering (SLS) 3D Printing?”, YouTube, https://www.youtube.com/watch?v=848x-5rKhNk

- Deloitte Insights, “Sheet lamination: Ultrasonic consolidation”, Additive Manufacturing for Business, LinkedIn, https://www.linkedin.com/learning/additive-manufacturing-for-business/sheet-lamination-ultrasonic-consolidation

- N.d., “Sushi Teleportation”, Team Open Meals Japan Patent Pending, https://www.open-meals.com/sushiteleportation/index_e.html

- N.d., “.CUBE”, Team Open Meals Japan Patent Pending, https://www.open-meals.com/cube/index_e.html

- N.d., “Cyber Wagashi”, Team Open Meals Japan Patent Pending, https://www.open-meals.com/cyberwagashi/index_e.html