Wesley Bull, Interdisciplinary Sculpture, 2022

Wesley Bull is a sophomore majoring in interdisciplinary sculpture at Maryland Institute College of Arts. His skills range from traditional mediums like drawing, printmaking, wood, and metal to digital fabrication. His concentration focuses on a theoretical explanation of the evolution of the universe; by relating the topic of time and space through the context of art as a material (time) and a technique (space).

Skill Building

A series of technical exercises build and demonstrate skills in Rhino, laser cutting, 3D printing, and CNC routing.

Rhino

Laser Cutting

3D Printing

Grasshopper

Chapter 1-4

Chapter 5-6

Data Trees: Chapter 1-4

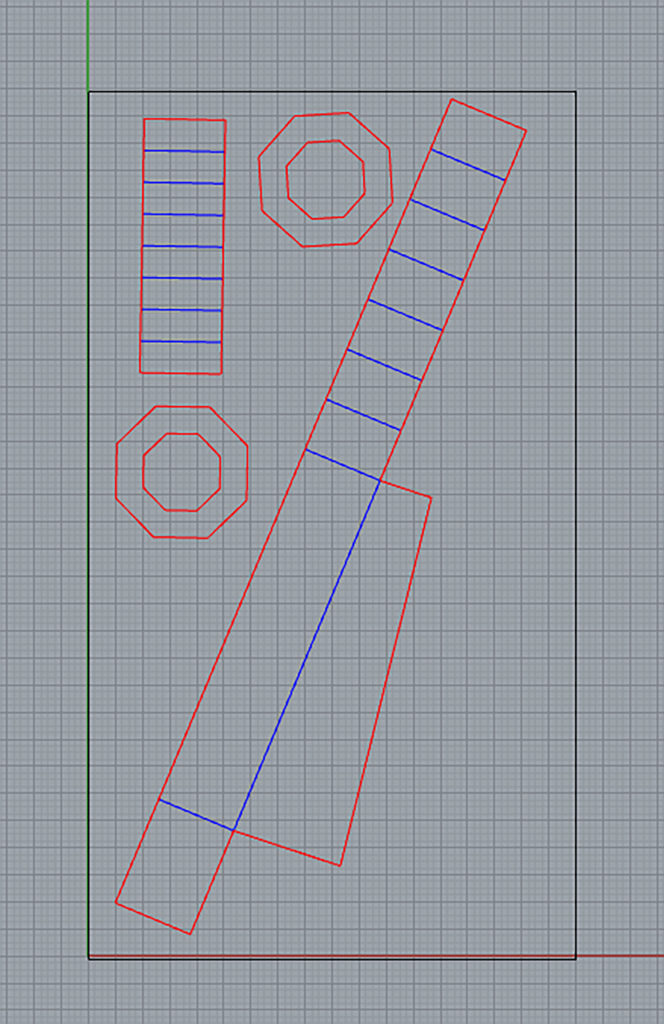

Project I: Laser cutting assignment

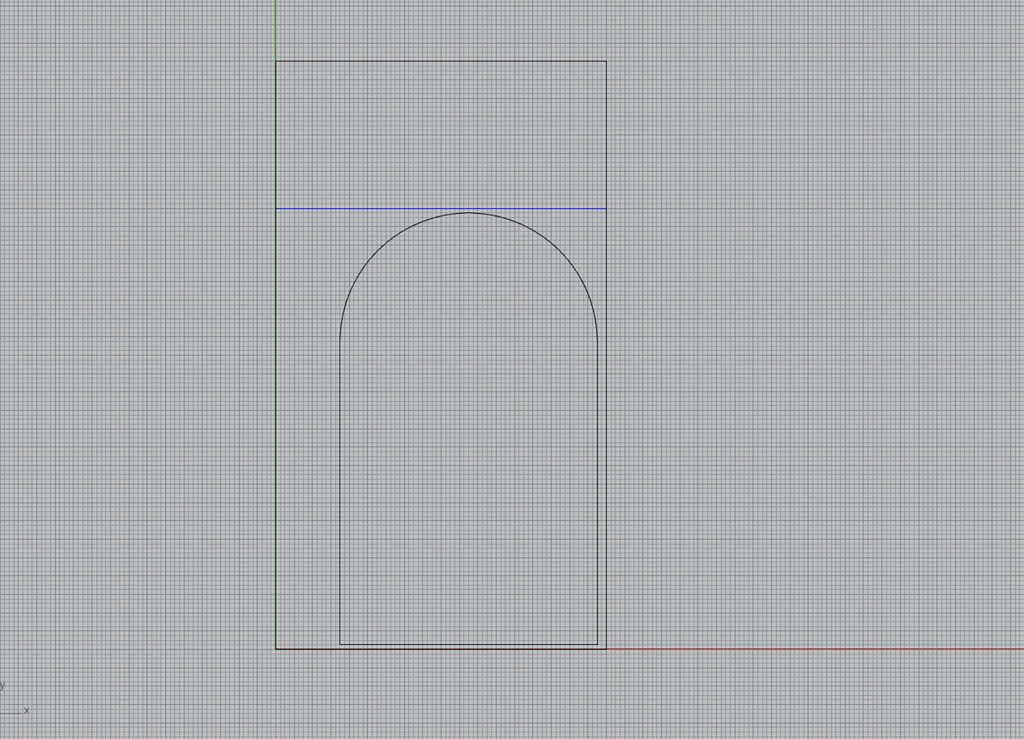

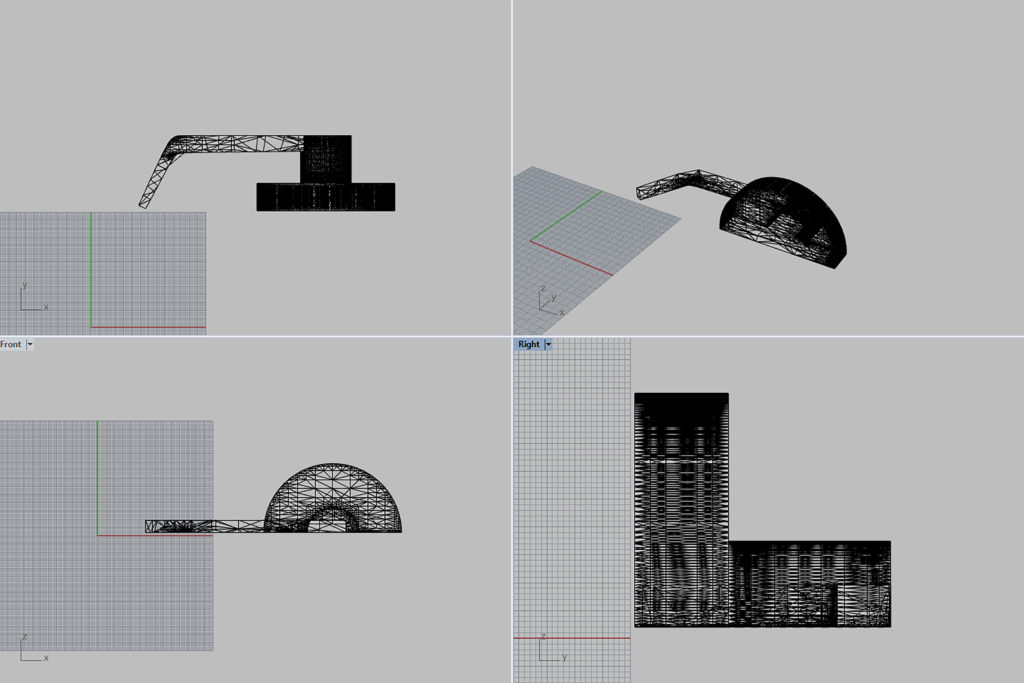

For our first project we were assigned to use a process in rhino to translate our work from 2-D to 3-D, then by using the laser cutter to transform it into physical form from 2-D back to 3-D. We were also asked to incorporate two or more materials; one being soft and one being ridge and to use the engraving technique on the surface of the material. By using the command “extrude” to give 2-D geometry depth and the command” unroll” to the 3-D geometry to create a flattened surface I was able to produce a sculpture of a simple spiral staircase. The support structure of the sculpture is made of cardboard with a wooden pillar in the middle, and the surface of the steps are made on laser engraved Bristol paper.

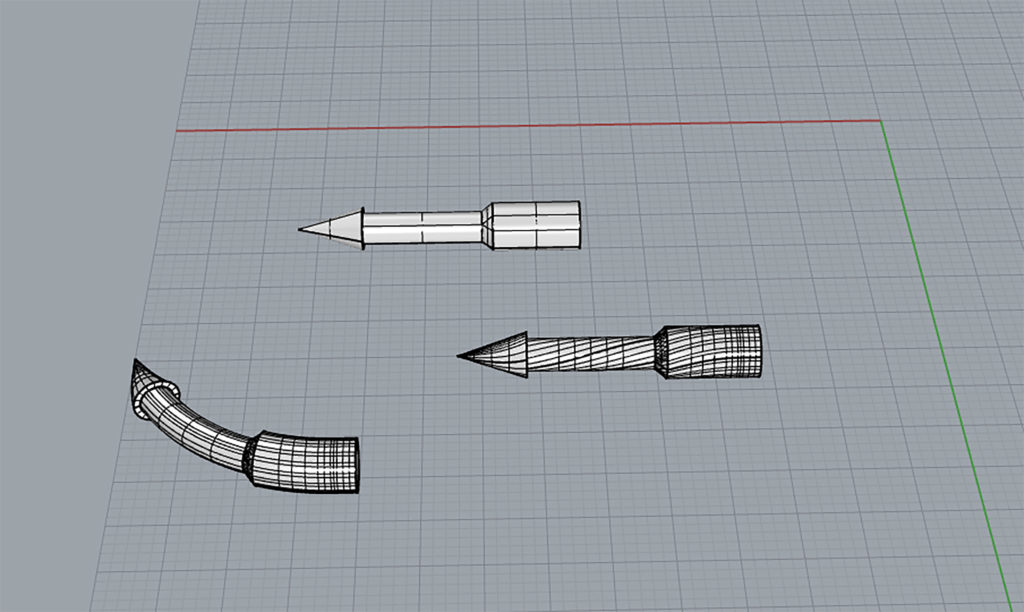

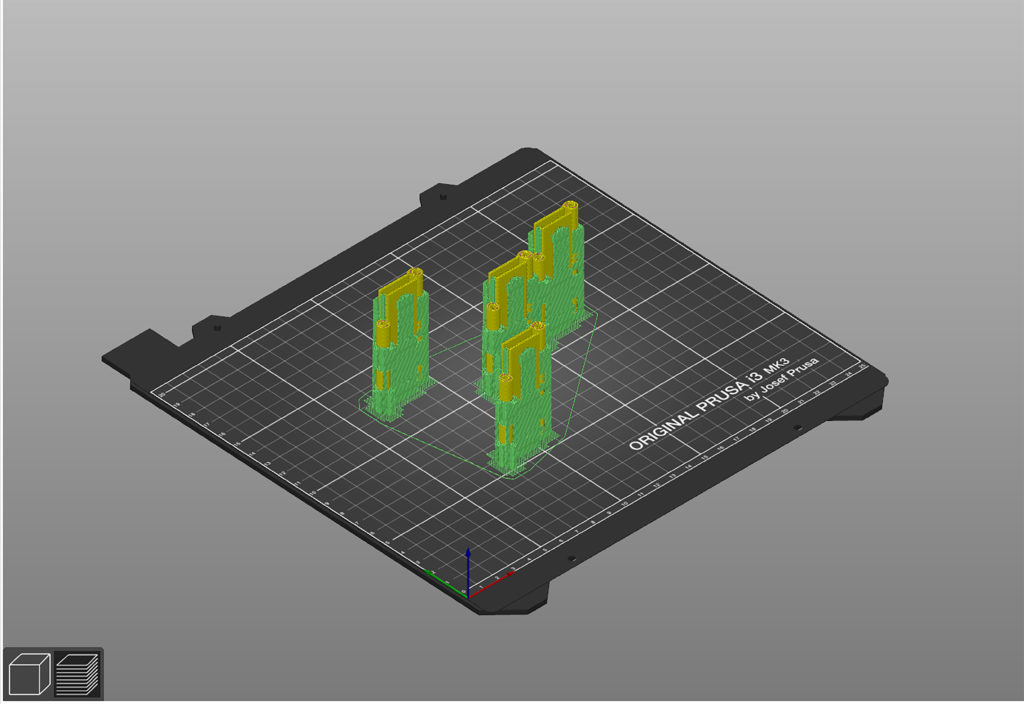

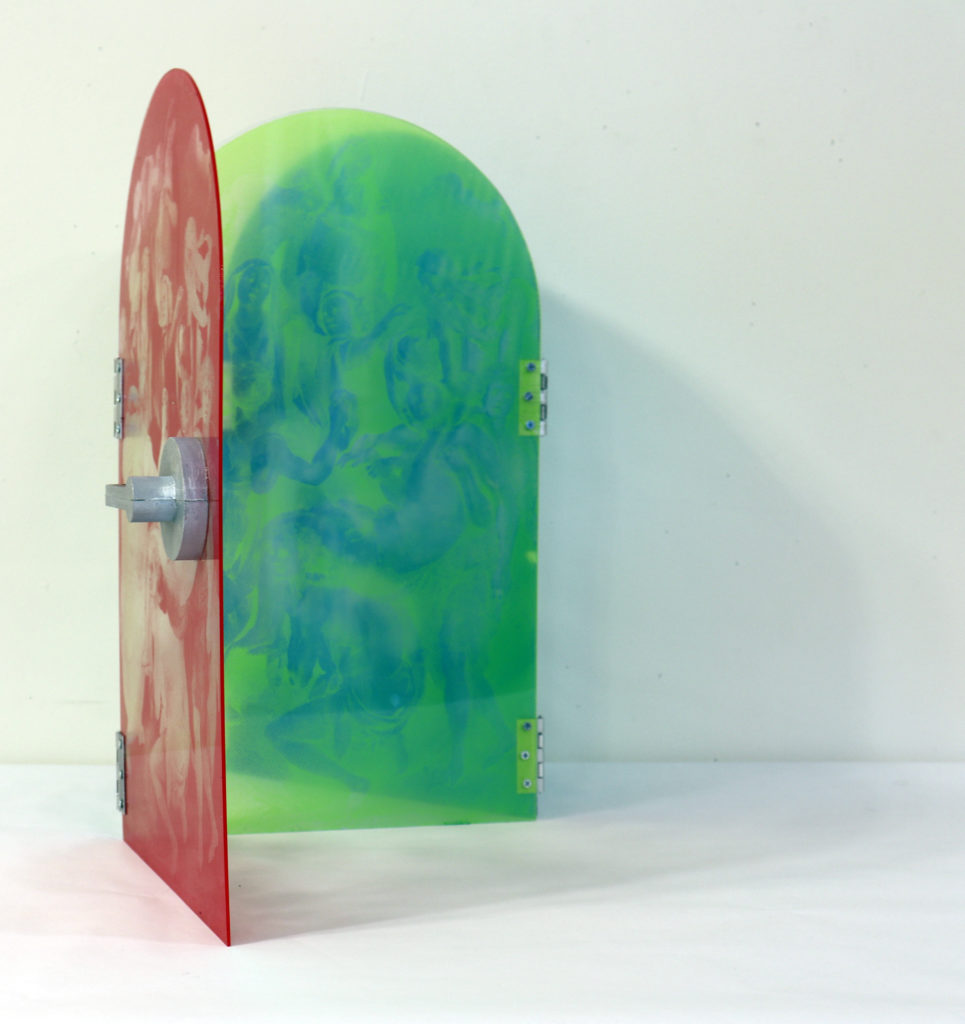

Project II: 3-D printing and modeling assignment

Our assignment for the second project was a two-part task; first, to use rhino to create an accurate 3-D model of an object of our choosing and 3-D print it. Secondly, we were to take our model and manipulate so it becomes incorporated in a found object of our choosing. For my piece, I modeled a 6,3 cm door hinge made of zinc, once I made my prints I incorporated them into a series of acrylic sheets that have been silk-screened on. Each sheet of plastic is split into R, G, B (red, green, blue) channels and printed with CMYK (cyan, magenta, yellow) inks. I attached a 3-D print of a door handle so the audience could interact with the piece by opening and closing the surfaces.

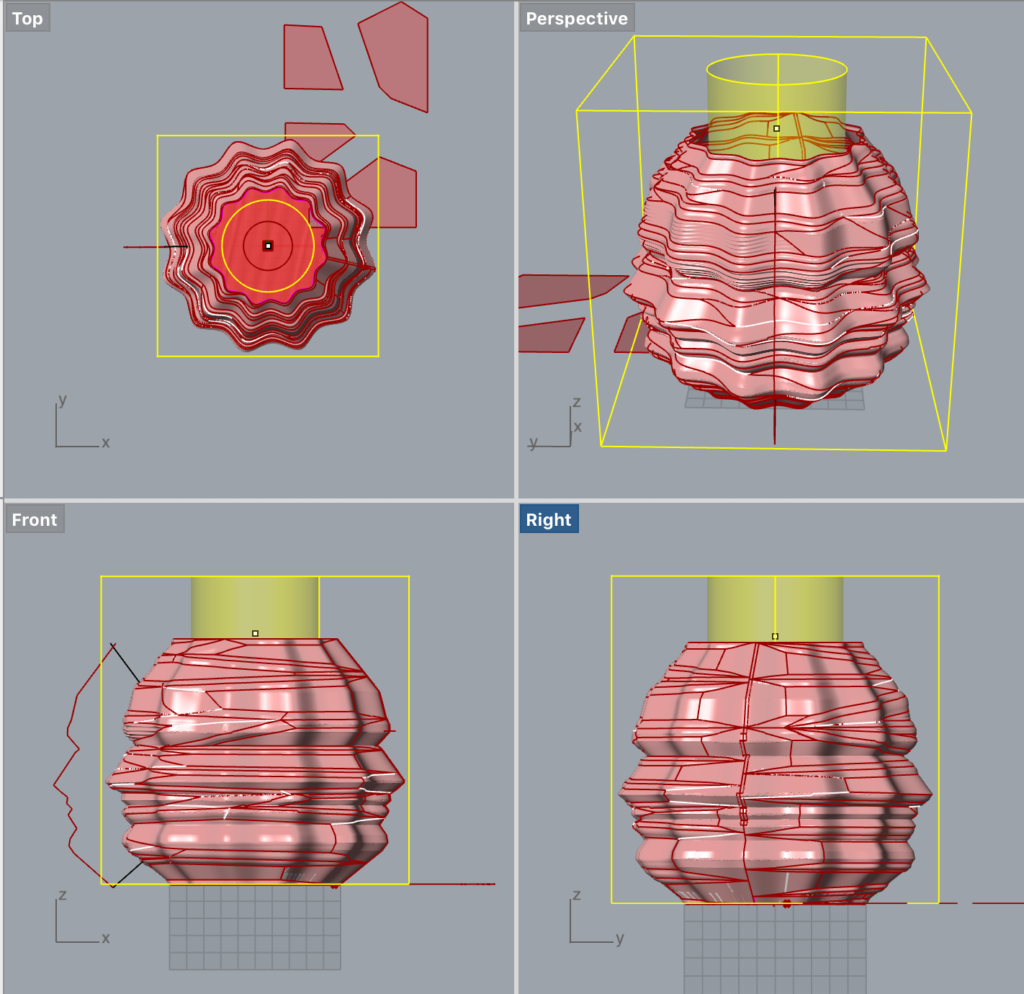

Project III:

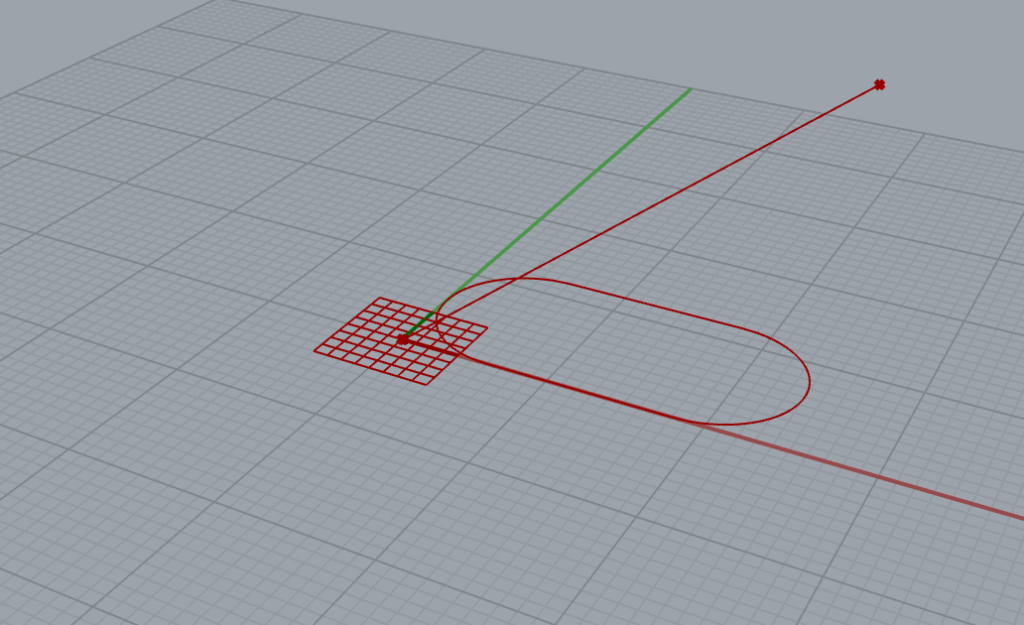

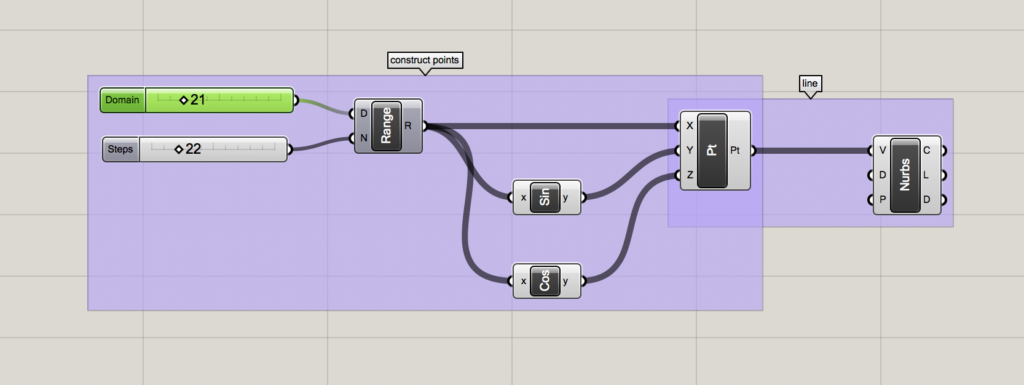

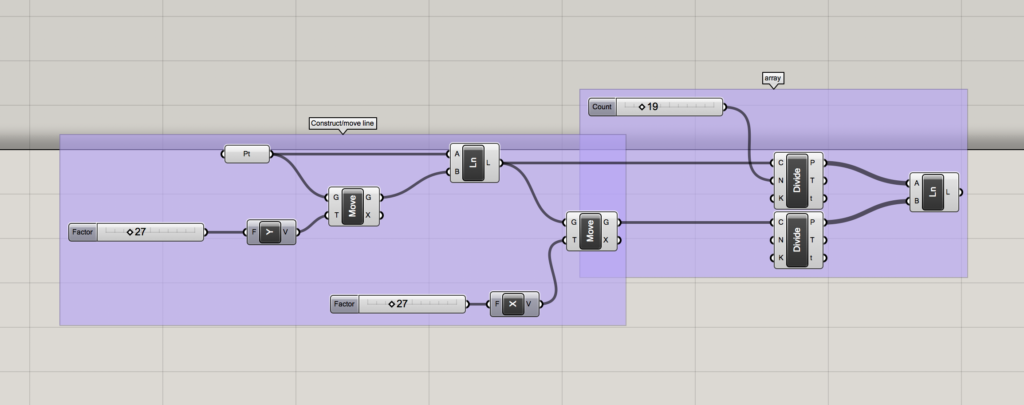

In our final project, we were assigned to use grasshopper to create 3d geometry in collaboration with our classmate’s geometry. This was executed by referencing the previous person’s bottom curve and installing it into your own definition. Then we would proceed to use the slicer component to create Gcode for the 3d printer. We had to reference the previous person’s bottom curve so when everyone’s piece printed they are able to stack one on top of each other. The piece is a collection of all of our class prints standing on top of each other with light installed running down the center of the hollow container. The piece is 9ft tall and made of a flexible white plastic filament and LED lights. My piece is based on a profile image of a human face. It was made in grasshopper by using a rotate command to make it 3d and a project command to install the Voronoi pattern onto the surface.

https://dfabclass.com/intro/wp-content/uploads/2020/02/Wesley_Intro_Dfab_Final.gh

Process

–

Research

The research presentation explains of ways of using digital fabrication in the future of space travel. It explores abstract examples of how these technologies can be implemented and questions our future existence.

More Information

additional information and links