Important precursors

Before we talk about 3D printers and the RepRap project specifically, a brief primer on how we got here.

Computer Numeric Control and G-code

It’s worth taking a minor detour to discuss early forms of automated machine control. Of course, our modern 3D printers use G-code, as do many of the other machines in our lab. When you do cursory research on the development of G-code, you will find that yes, G-code originated in the MIT Servomechanisms Laboratory in around 1958, and before that, most folks point to inventors like Eli Whitney as one of the progenitors of the automated milling machine, which often used a hole punch system, which would then evolve into G-code. However, I think considering that the whole story would be doing a disservice to the Jacquard loom, which is an excellent early example of automated machine control. It functions in similar manner, with a punched card to control the movements of the loom, and it’s worth noting that many consider the Jacquard loom to have directly inspired early computing systems like Charles Babbage’s Analytical Engine (one of Babbage’s contemporaries, Ada Lovelace, even said as much). So it’s not a total stretch to suggest that without the Jacquard loom, there may not have been computers to run G-code on.

FFF/FDM

Another important topic is how the FFF/FDM (Fused Filament Fabrication/Fused Deposition Modeling) technique developed. The concept of fusing deposited material together to form a larger whole is hardly new. And the specific approach that most 3D printers use, often referred to as Fused Filament Fabrication (FFF) or Fused Deposition Modeling (FDM), was pioneered by Stratasys in 1988. We often joke about this style of printers being essentially a “robotic hot glue gun”, but truly, the initial prototype created by Scott Crump of Stratasys used a hot glue gun and a “mixture of polyethylene and candle wax”. Stratasys also developed the first “slicer” software, that would take stereolithography (STL) files and determine how the layers would be printed.

So what is RepRap?

The concept of RepRap was first conceived by Adrian Bowyer, a professor of Mechanical Engineering at the University of Bath in the United Kingdom. In 2004, Bowyer published a manifesto online (complete with mentions of Marx and Engels, which is awesome!), describing his vision for the machine, as a “self-replicating machine”, akin to the “Universal Constructor” device proposed by mathematician/physicist John von Neumann in the 1940’s. The purely hardware goal was specifically to create a machine that could make all of its components, other than self-tapping steel screws, brass bushes, lubricating grease, standard electronic chips such as microcontrollers and optical sensors, a standard plug-in low-voltage power brick, and stepper motors.

From a cultural and philosophical standpoint, Bowyer saw the idea of the RepRap as something capable of a form of natural selection/evolution. By making the designs open-source, and included with every machine, in theory, anyone could take the CAD files, make their own modifications, and republish them back into the ecosystem, where the new design would be continually iterated on and continue to evolve.

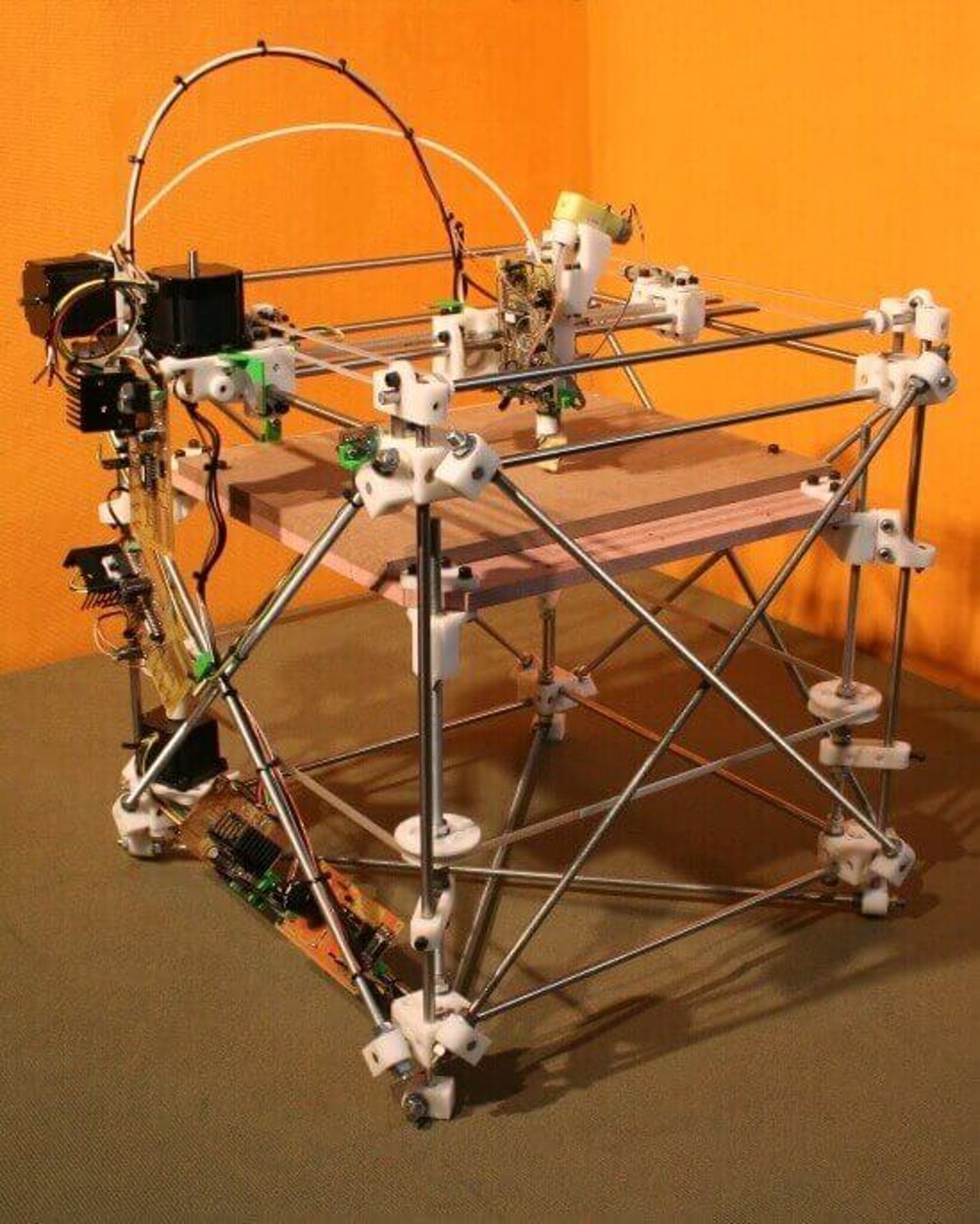

A team consisting of Bowyer and several of his doctoral students began work on the RepRap project in March of 2005, after receiving funding from the UK’s Engineering and Physical Sciences Research Council. By September of 2006, an early version of the RepRap printed the first part identical to its own, which was used as a replacement for the original part created by a commercial-grade 3d printer. The 1.0 release, “Darwin”, launched in 2007. At this point we start to see some additional players on the software side of things, as in addition to RepRap Host (a GUI control for the printer as well as a slicer), Skeinforge (a Python based slicer, that most modern slicer software derives from in some way), enters the scene.

The Darwin and the RepRap ethos were certainly picking up steam at this point, and had become a bit of a sensation in colleges and makerspaces, but it was not without its flaws. Namely, that a Darwin took around 100 hours of print time to print parts to create another Darwin, and that the software/electronics side of things was not particularly user-friendly (especially for beginners).

That would soon change after the 3D printing movement really started in earnest, when Stratasys’ patent on Fused Filament Fabrication expired in 2009. This meant that the technique could be used without having to pay Stratasys for the privilege. 2009 is also the year Adrian Bowyer and other RepRap volunteers helped to found MakerBot, one of the first 3d printer companies based off of RepRap. Love it or hate it, this was a huge turning point for the growth and development of 3d printers.

The RepRap team did make some more improvements of their own, releasing the “Mendel” version of the RepRap in late 2009, and a miniaturized version known as “Huxley” in 2010. But the floodgates have now well and truly opened, and we start to see the creation of some of the 3D printer companies that are now mainstays today, with both Ultimaker and Aleph Objects (Lulzbot) in 2011. And perhaps most notably for us, Prusa, which got its start making remixed versions of the RepRap Mendel, was officially founded in 2012.

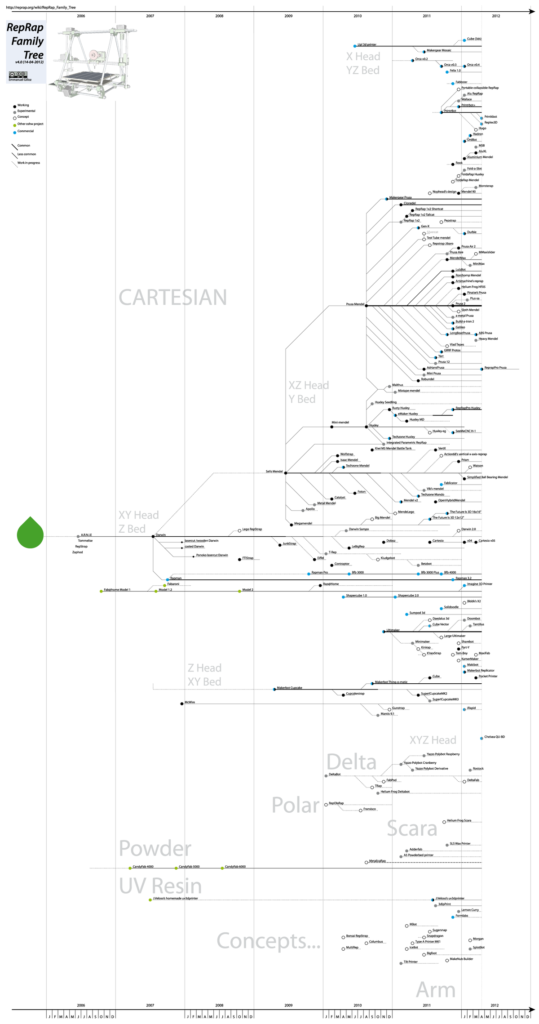

Now, we can start to take a look at the RepRap “family tree”…

RepRap family tree

Here you can see the original Darwin, then the Mendel, Prusa Mendel, Huxley, etc. Also note the MakerBot Cupcake sitting somewhat separately but shown progressing in tandem.

…and here’s the complicated version. No, I don’t know why they decided to format it like this. Yes, I promise it’s actually really fascinating when you can actually read it.

As you can (hopefully) see, this tree denotes some of the different technologies/approaches to 3D printing that evolved separately from or alongside the RepRap project. We’re going to talk about a few of those now.

Different form factors, techniques, and modifications…

SLA/DLP (resin) printers

SLA (Stereolithography) printers, DLP (Digital Light Process), or resin printers, have also been around a while, but until recently, they’ve mostly remained more industry-level machines. But in the past few years we’ve seen more consumer-grade resin printer designs, including this Creality one.

Resin printers are generally superb in terms of precision and surface quality, but they can be annoying to work with, due to the messy and potentially dangerous nature of the resin, and they’re a little limited, especially in the bed size department, as if you go much bigger than something like the printer pictured here, you start to run into issues with the laws of physics.

SLA and DLP are both resin-based, but operate in slightly different ways. SLA uses a laser beam to draw the profile of a layer onto the bottom of the resin vat. DLP projects a complete layer all at once onto the bottom of the resin vat.

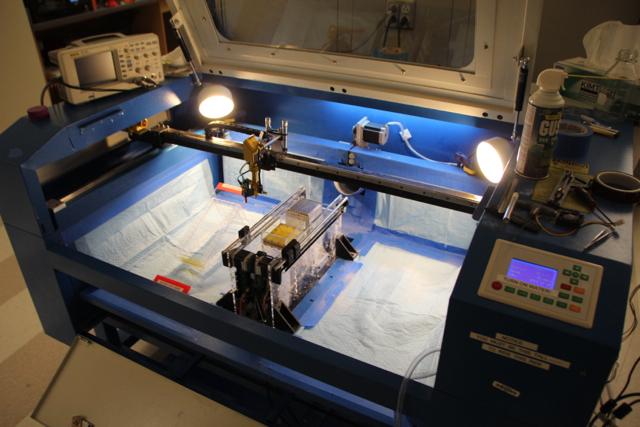

SLS (powder sintering) printers

SLS (Selective Laser Sintering), or powder sintering printers, are extremely cool, and have some neat advantages (again, high precision, and oftentimes the ability to work with more advanced materials, like metals), but are even worse than resin printers in terms of how consumer-friendly they are. They’re messy, have a lot of overhead/management concerns, and currently quite expensive and hard to miniaturize. This photo here is of the OpenSLS project, an open-source attempt to build an SLS machine. I think that casing used to be a laser cutter. It cost around $15,000 to make, which is certainly a success compared to the price of industry versions, but it’s still not exactly a palatable price to most consumers.

Delta printers

Delta printers are a bit of an oddball design offshoot from the traditional linear XYZ axis designs, like Cartesian and CoreXY. As you can see, they use three arms to move the toolhead from one point to another by adjusting the angles of the arms.

The delta design used to be known for having a few advantages over the traditional approach, namely a taller build height, as well as speed. They’re still around today, but these days those advantages are getting smaller and smaller compared to modern traditional designs, and they have always had some significant cons, mostly that they can be much less straightforward to tune correctly to get decent results.

Infinite Z/”treadmill” printers

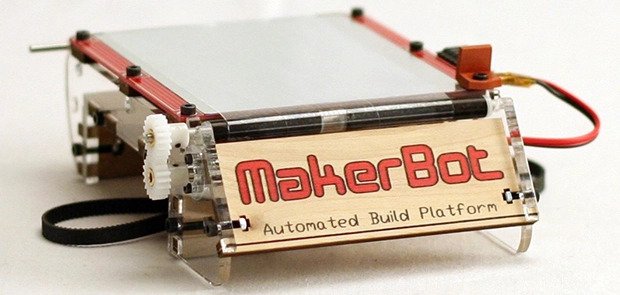

The idea of creating an infinite Z axis on a 3D printer is not new. While most recently, Naomi Wu and Creality have launched the 3DPrintMill printer, MakerBot had the ABP (Automated Build Platform) almost as long as they’ve been making their own 3d printers. It had a lot of problems, and the idea didn’t really catch on, but with the 3DPrintMill, there seems to be some renewed interest, as it fills a very particular niche for people who really benefit from such a large (theoretically infinitely large) work area, folks like prop makers, set designers, signmakers, etc.

Dual/multi extrusion printers

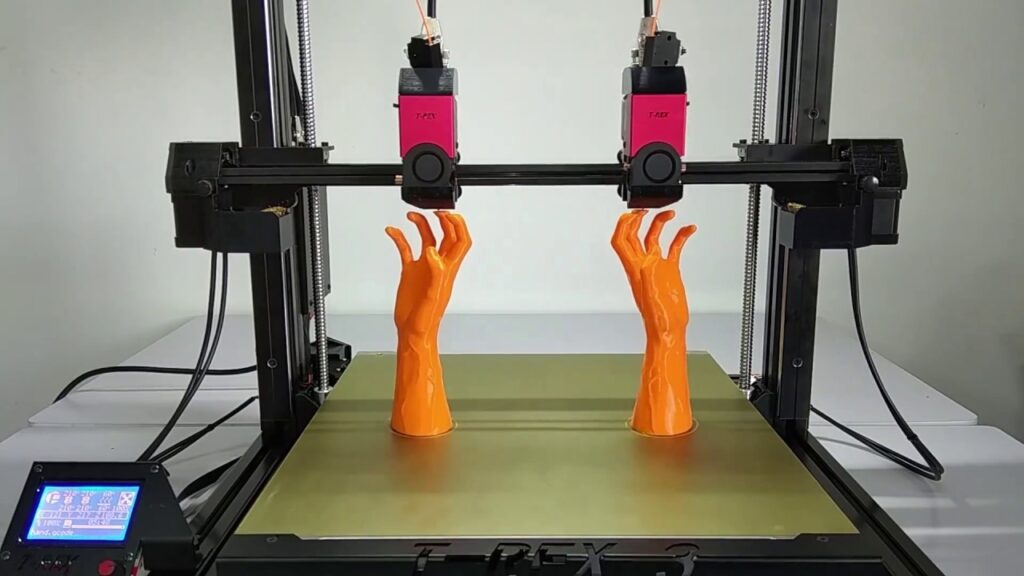

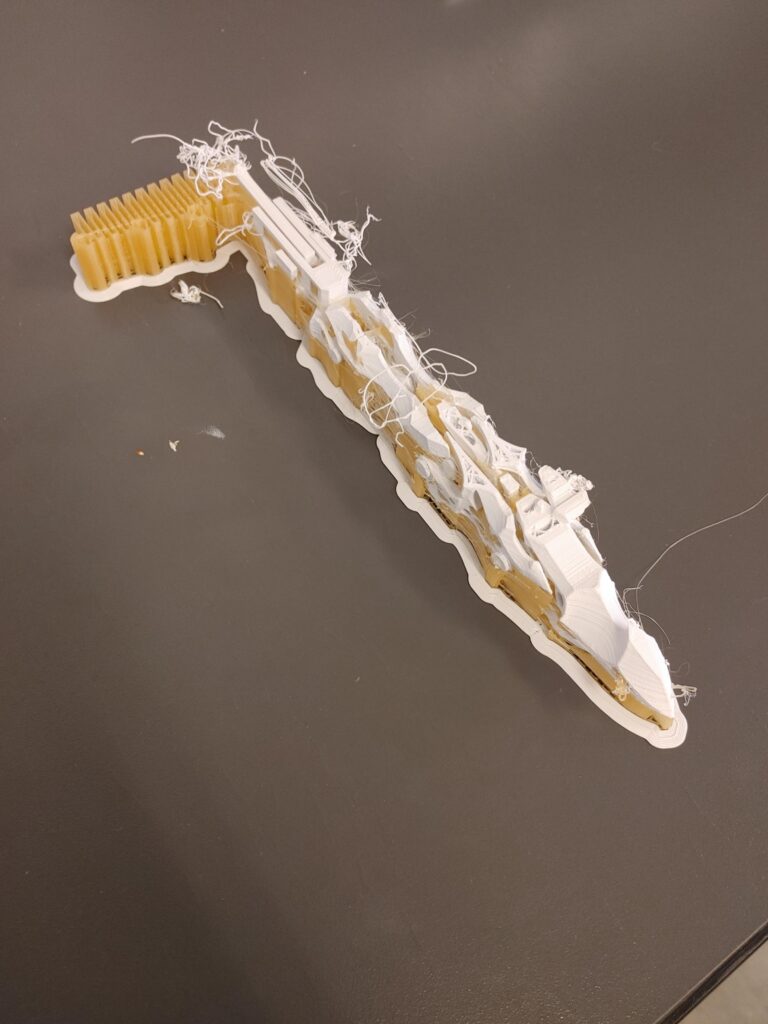

Dual extrusion printing is, as the name suggests, printing with two extruders at once, allowing for the use of multiple colors or multiple materials at once.

Dual extrusion can be accomplished with a new/modified toolhead that puts two nozzles on the same toolhead, or by having two separate toolheads that can move independently, which is often referred to as IDEX (Independent Dual Extruder). The printer pictured here takes the IDEX approach, which has some benefits, but also a notable drawback, which is easy to spot if you take a look at the image above: by having two independent toolheads that move on the same axis, you’re effectively cutting your build volume in half.

Multiple colors is nice and all, but I think the real potential here lies in being able to print with stuff like water-soluble PVA filament as your support material, so you can run prints that would otherwise be almost completely impossible to print without leaving support material behind.

As I’ve learned, it can be…a bit finicky.

In summary

The roots of RepRap run deep, and it’s more than fair to say that the project was the catalyst for the explosion of the 3D printing hobby and market. Nearly every 3D printer we use today owes at least something to the RepRap project.

Things to think about?

1: How successful do you feel the RepRap project was, either in terms of hardware or in terms of culture/ethos?

2: Not to ask y’all to predict the future, but, what areas of 3D printing seem like they hold the most promise to you/where do you think 3D printing tech is going in the future?

3: As 3D printers become move closer and closer to the realm of a straight up consumer product (you can buy a cheap one for less than $200 on Amazon, and it’s not half bad), rather than something just for hobbyists, there’s less and less of a need to start from scratch/tinker as much with a 3D printer these days. Is it possible that that’s somewhat stifling creativity?

Works cited

Fused Deposition Modeling (FDM) | WhiteClouds – WhiteClouds. (2021, October 10). Retrieved from https://www.whiteclouds.com/3dpedia/fdm

Wealth Without Money – RepRap. (2021, August 16). Retrieved from https://reprap.org/wiki/Wealth_Without_Money

The Official History of the RepRap Project. (2021, November 19). Retrieved from https://all3dp.com/history-of-the-reprap-project

Our Story | Original Prusa 3D printers directly from Josef Prusa. (2022, May 08). Retrieved from https://www.prusa3d.com/page/our-story_875

OpenSLS – An Open Source Project Creates a Sub-$15K Selective Laser Sintering 3D Printer – 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. (2021, October 17). Retrieved from https://3dprint.com/5104/opensls-sls-3d-printer

3D Printering: A Call For An Open Source Automated Build Platform. (2014, December 05). Retrieved from https://hackaday.com/2013/10/23/3d-printering-a-call-for-an-open-source-automated-build-platform